Inverter AC waveform control method and control circuit

A technology of inverting AC and control methods, which is applied in the direction of irreversible DC power input conversion to AC power output, AC power input conversion to DC power output, electrical components, etc. , high voltage spikes and other problems, to achieve the effect of improving anti-interference ability, reducing arc noise, and reducing overvoltage spikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention are described in detail below:

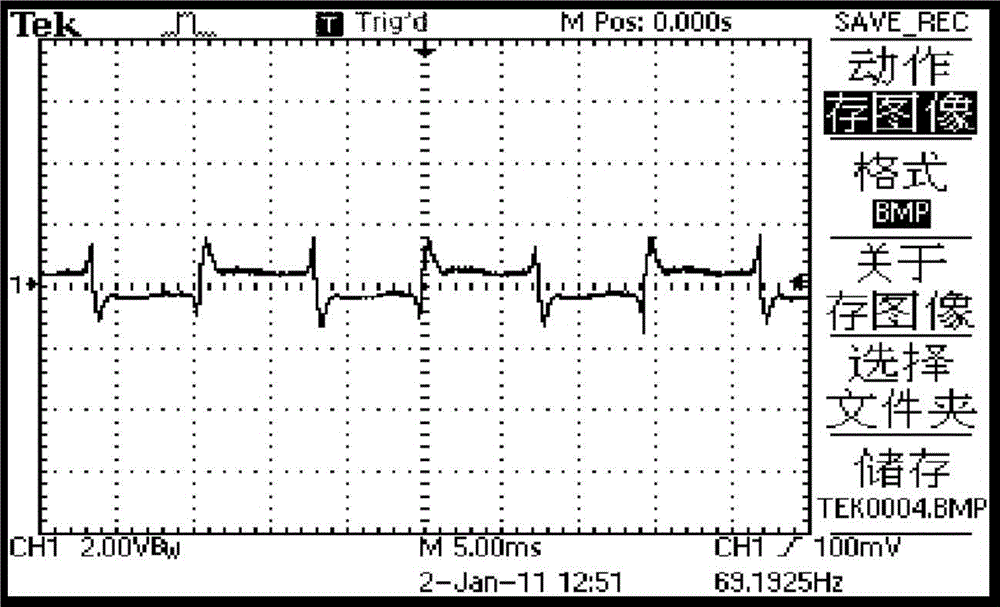

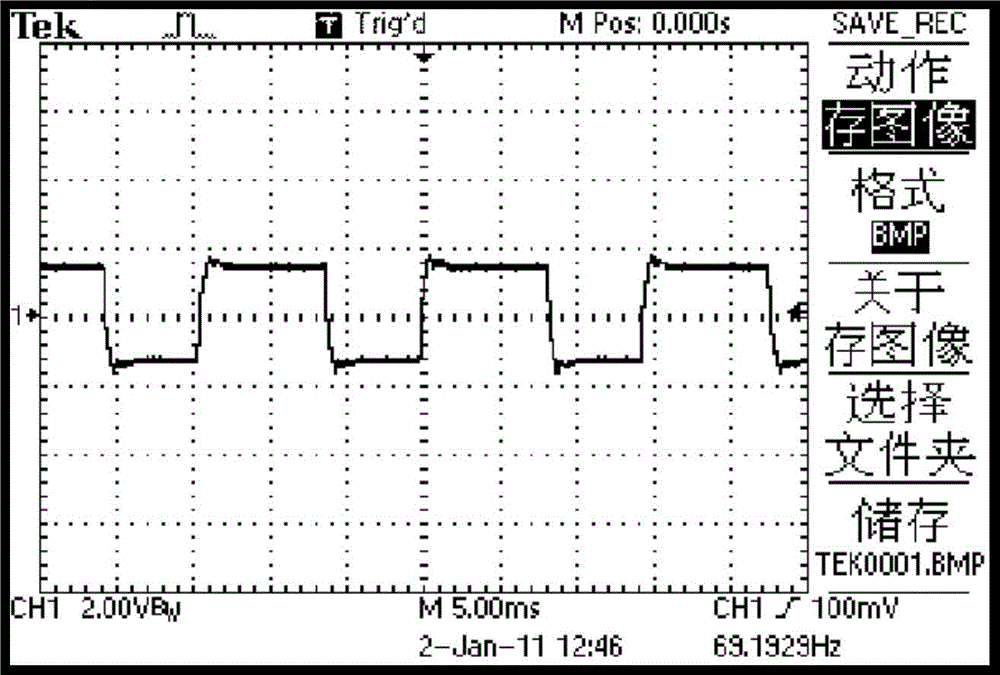

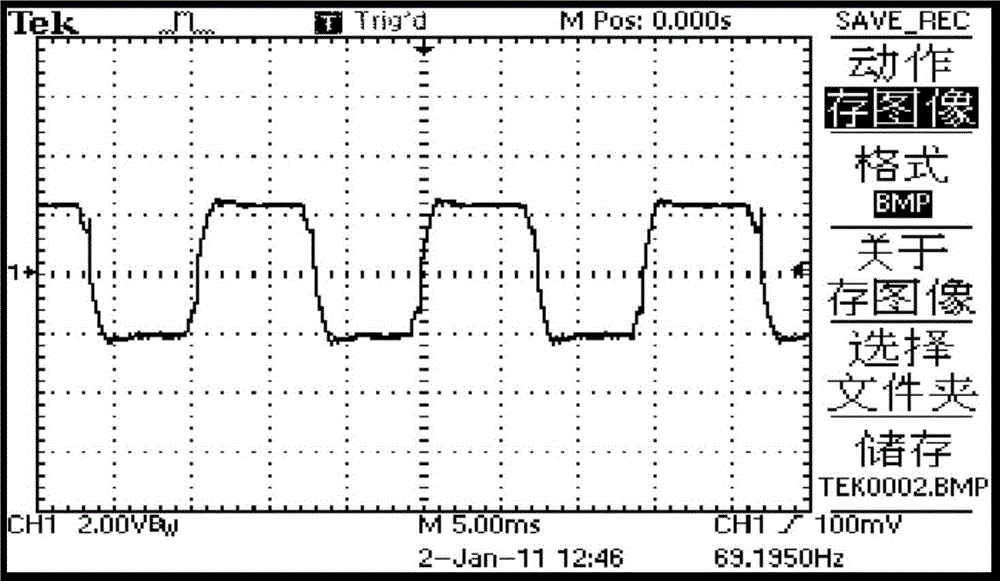

[0046] Such as figure 1 As shown, the inverter AC waveform control circuit of the present invention includes a logic sequence circuit 10 , a waveform control circuit 20 and a secondary inverter circuit 60 . The working circuit of the welding machine with the inverter AC waveform control circuit described in the embodiment of the present invention also includes a pulse width modulation circuit 30, a primary inverter circuit 40, a high-frequency transformer step-down and rectification circuit 50 and an output terminal.

[0047] Such as figure 2 As shown, the logic sequence circuit 10 has an inverter trigger signal output terminal OUTA, OUTB and a wave control pulse signal output terminal BK. The inverter trigger signal output terminals OUTA, OUTB are connected to the input terminal of the secondary inverter circuit 60 . The wave control pulse signal output terminal BK is connected to the input termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com