Centering mechanism

A technology of centering mechanism and rack shaft, applied in metal processing machinery parts, clamping, supporting and other directions, can solve the problems of small bearing force, complex overall structure, large space occupation, etc., achieve small errors, simple overall structure, Easy to center effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

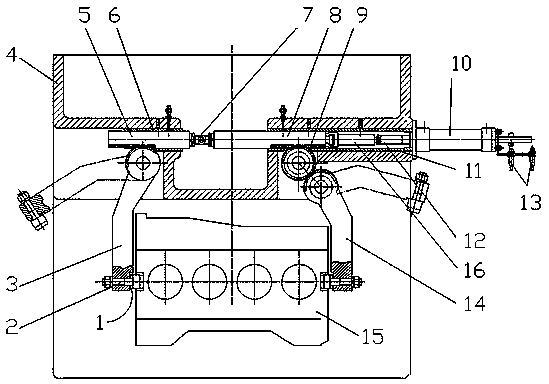

[0010] Such as figure 1 Shown: 4 is a frame, on which an axially movable rack shaft is installed on the frame 4, the rack shaft includes a second rack shaft 8 that is in phase with the connecting shaft 16, and the second rack shaft 8 connects with the connecting head 7 The first rack shafts 5 are connected. A guide sleeve is provided between each rack shaft and the frame 4, and the guide sleeve includes a first guide sleeve 6 and a second guide sleeve 11, the first guide sleeve 6 is located between the first rack shaft 5 and the frame 4, and the second guide sleeve The sleeve 11 is located between the second rack shaft 8 and the frame 4 . The connecting shaft 16 is connected with the end of the piston rod 12, and the oil cylinder 10 matched with the piston rod 12 is fixedly connected with the frame 4 and connected with the hydraulic control device. Each of the above-mentioned rack shafts is processed with a part of the rack on the shaft, and the rack part is exposed from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com