Automatic material discharging mechanism of bush press-in machine

A technology of automatic discharging and pressing machine, applied in the field of pressing machine, can solve the problems of increasing the fatigue strength of operators, occurrence of safety accidents, hidden dangers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

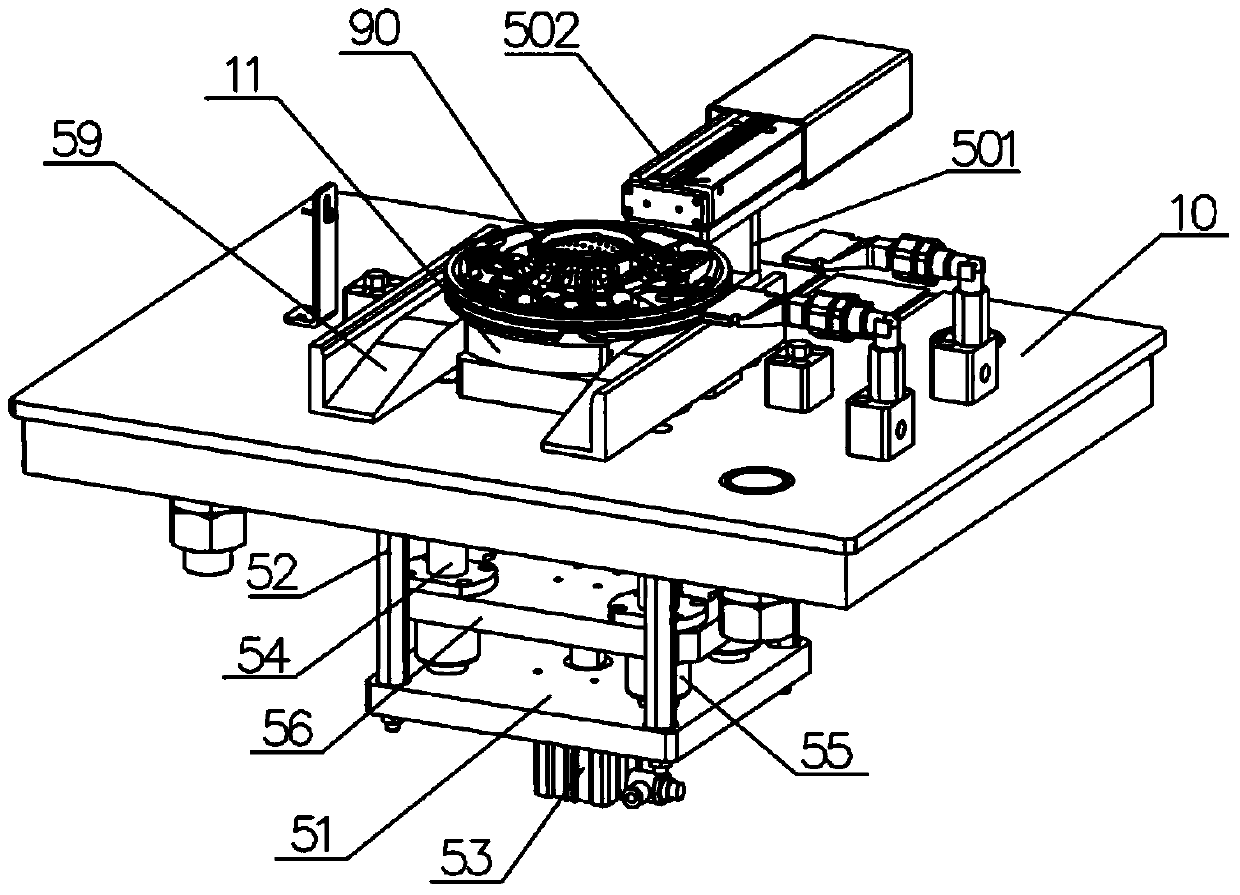

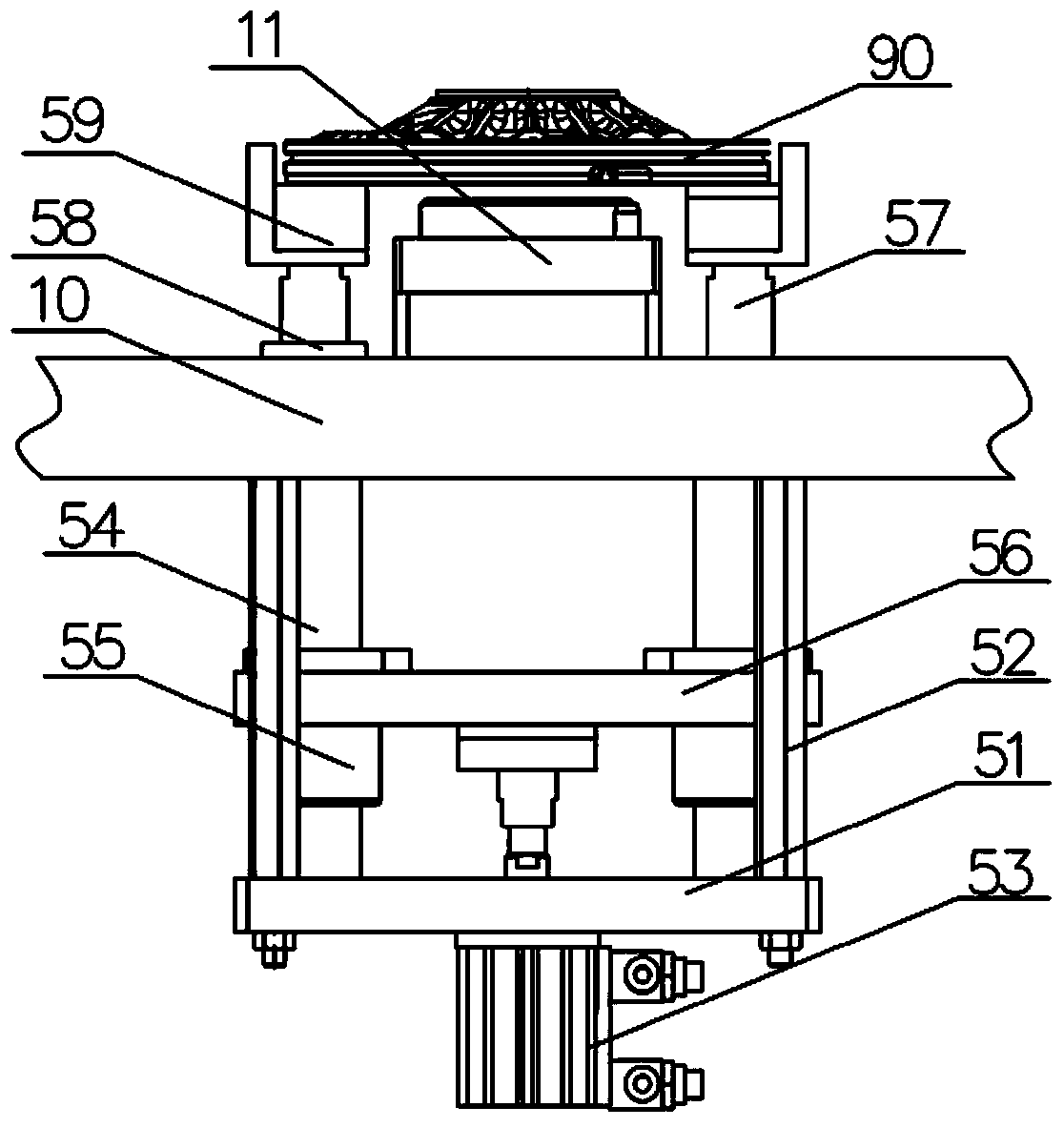

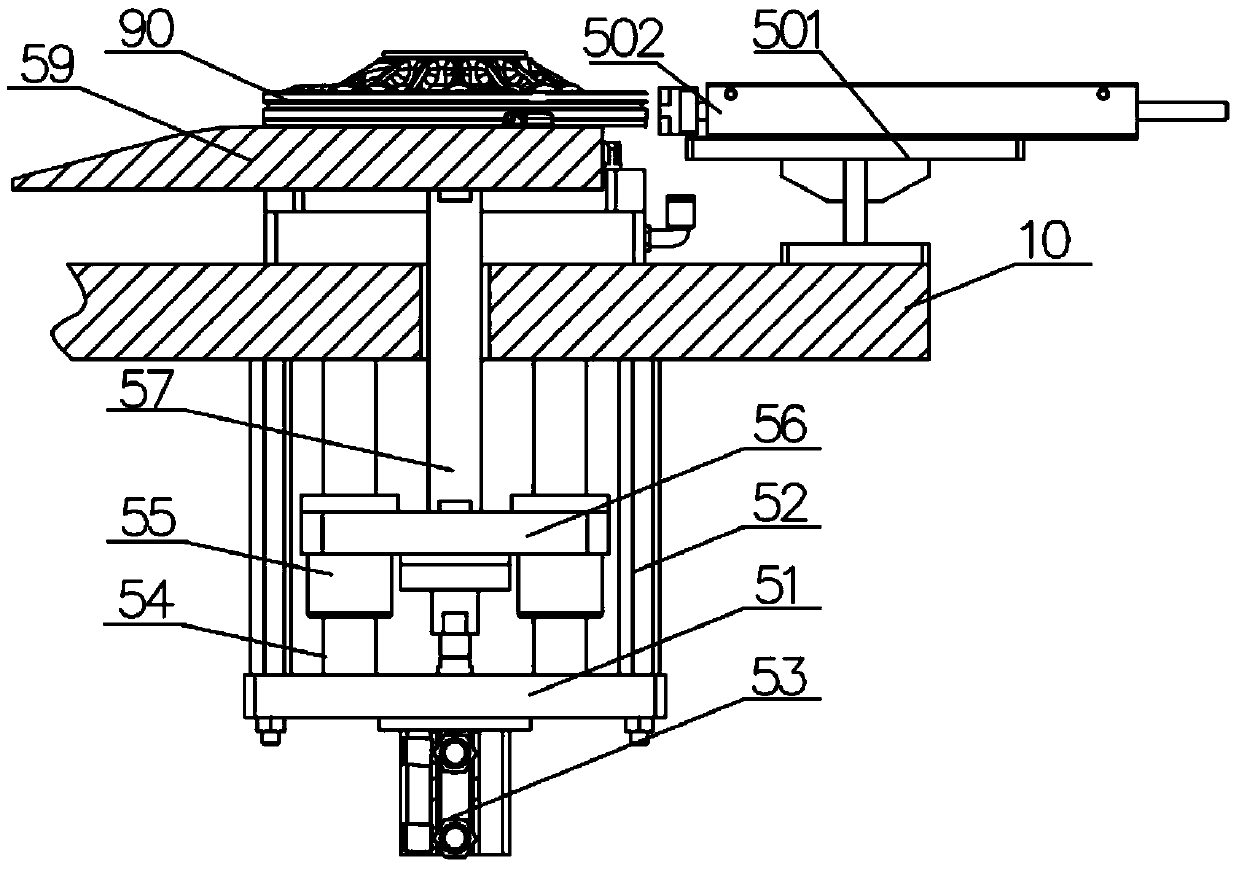

[0016] Example: see figure 1 , 2 , 3, the automatic discharge mechanism of the bushing press-in machine includes the workbench 10 of the frame, the workbench 10 is fixed with a workpiece placement platform 11, and the lower end surface of the workbench 10 is fixed with some hexagonal columns 52, hexagonal The column 52 is fixed on the base plate 51, and the lower end surface of the base plate 51 is fixed with a thin cylinder 53, and the piston rod of the thin cylinder 53 passes through the base plate 51 and is fixed on the lifting bracket plate 56, and the lifting bracket plate 56 is fixed with a linear bearing 55. A guide shaft 54 is sleeved on the bearing 55, and the two ends of the guide shaft 54 are respectively fixed on the workbench 10 and the base plate 51; An L-shaped discharge plate 59 is fixedly connected through the workbench 10, and the L-shaped discharge plate 59 is respectively located on the left and right sides of the workpiece placement table 11, and a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com