Pre-detecting method and controlling method for pressure refueling

A pre-detection and pressure technology, applied in the field of machinery, can solve the problems of reduced safety, lack of pre-detection control function, no pre-detection control, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

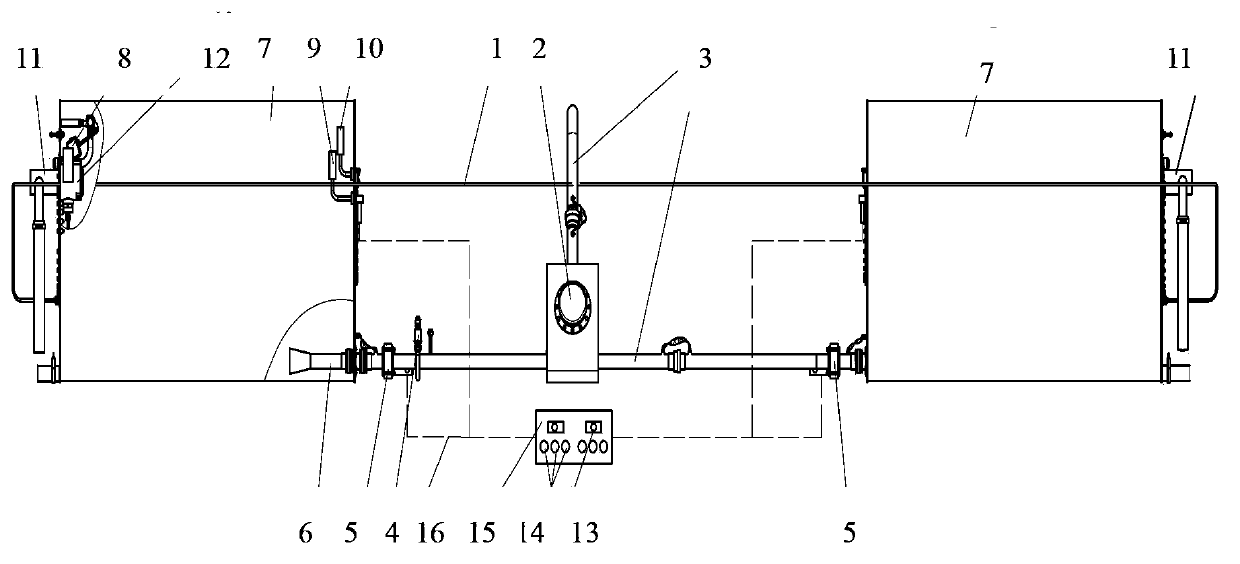

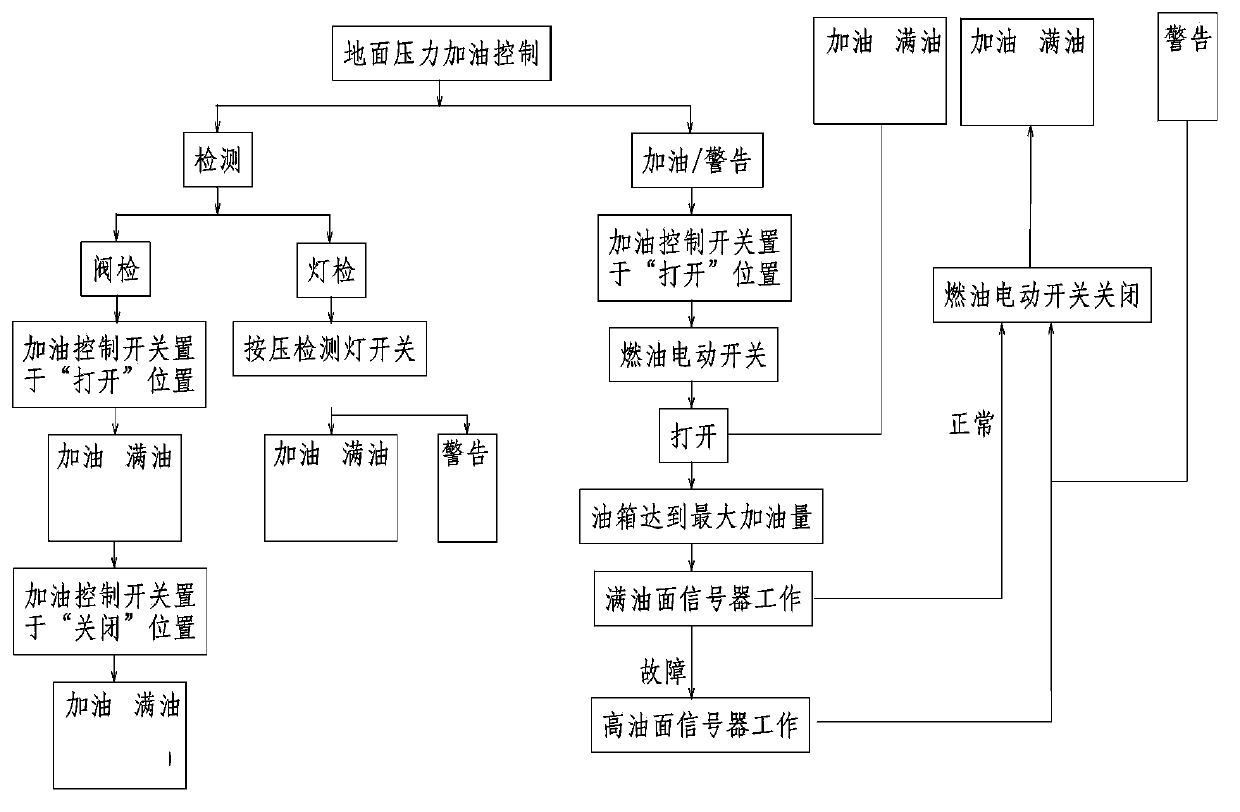

[0021] Combine below figure 1 , figure 2 To illustrate the working situation of the present invention:

[0022] The pre-testing method and control method of the pressure refueling system is a design method in which the theoretical design of the on-board pressure refueling system is simulated on the ground in advance. The length and the volume of the fuel tank are different from the design on the aircraft. The ground test can test whether the actual function of the pressure refueling system meets the various indicators required by the design.

[0023] The ground test structure of the pressure refueling system matched with the pre-detection method and control method of pressure refueling of the present invention is as follows: figure 1 As shown, it mainly includes a set of control pipeline 1, a refueling joint 2, a set of refueling pipeline 3, a vacuum valve 4, two fuel electric switches 5, two nozzles 6, two metal fuel tanks 7, two Float valve 8, two full oil level annuncia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com