A kind of polypropylene composite material with good appearance and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of polypropylene composite material and its preparation, can solve the problems of increasing tiger skin patterns and affecting the appearance of parts, and achieves the effects of enhanced compatibility, low cost and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

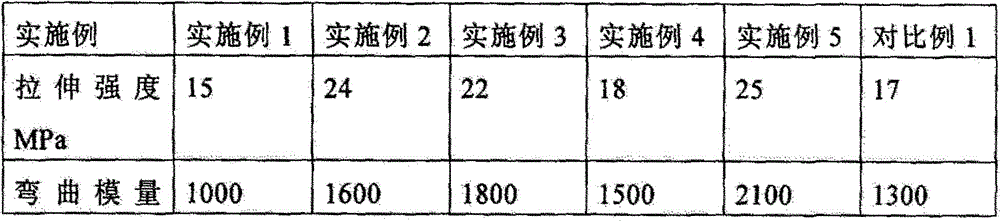

Examples

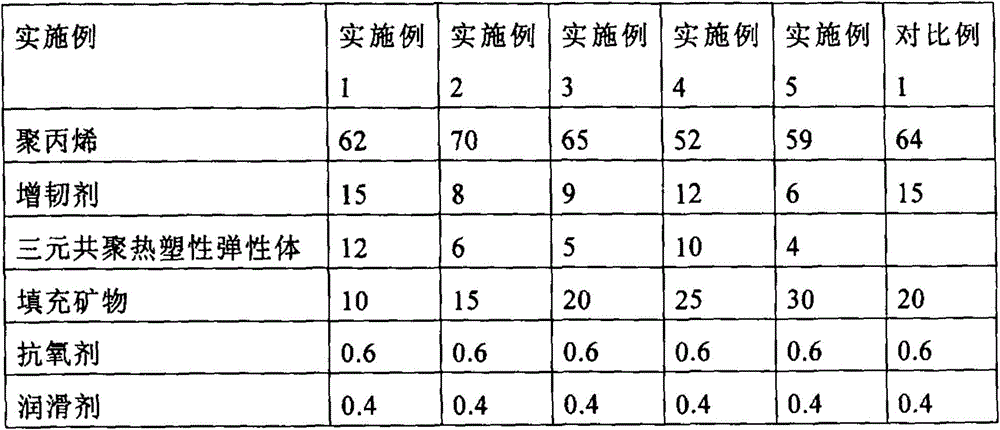

Embodiment 1

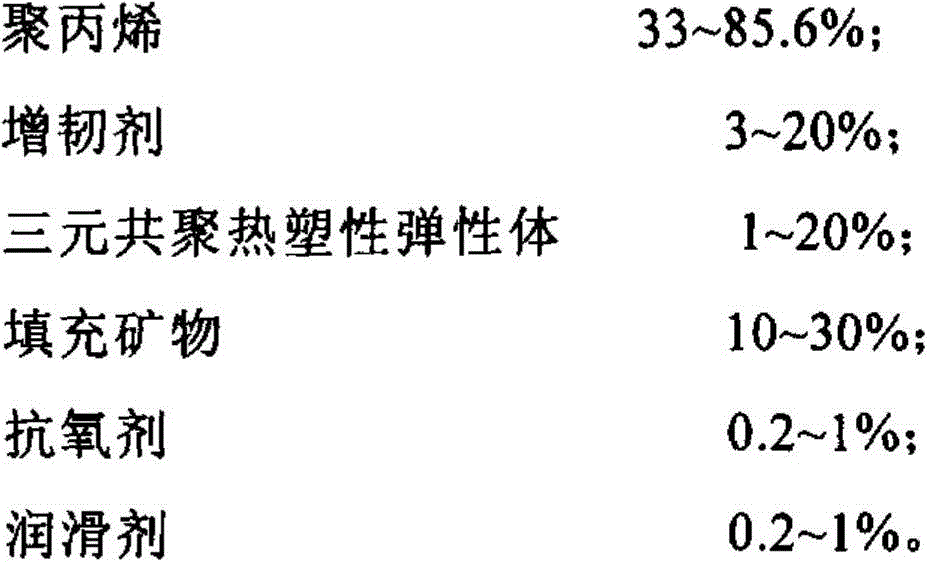

[0028] Prepare raw materials according to the following components and weight percent content:

[0029] Copolymerized polypropylene 62%;

[0030] Ethylene-octene copolymer 15%;

[0031] Ternary copolymerized thermoplastic elastomer 12%;

[0032] Wollastonite 10%;

[0033] Antioxidant 0.6%;

[0034] Lubricant 0.4%;

[0035] Put all the raw materials together into a high-speed mixer and mix for 2-5 minutes, and discharge; then put the mixed material into a twin-screw extruder to extrude and granulate to obtain a polypropylene composite material with good appearance. Wherein, the process temperature is 200° C., and the screw speed is 400 rpm.

Embodiment 2

[0037] Prepare raw materials according to the following components and weight percent content:

[0038] Copolymer polypropylene 70%;

[0039] Ethylene-octene copolymer 8%;

[0040] Ternary copolymerized thermoplastic elastomer 6%;

[0041] Calcium carbonate 15%;

[0042] Antioxidant 0.6%;

[0043] Lubricant 0.4%;

[0044] Put all the raw materials together into a high-speed mixer and mix for 2-5 minutes, and discharge; then put the mixed material into a twin-screw extruder to extrude and granulate to obtain a polypropylene composite material with good appearance. Wherein, the process temperature is 190° C., and the screw speed is 300 rpm.

Embodiment 3

[0046] Prepare raw materials according to the following components and weight percent content:

[0047] Copolymerized polypropylene 65%;

[0048] Ethylene-octene copolymer 9%;

[0049] Ternary copolymerized thermoplastic elastomer 5%;

[0050] Talc powder 20%;

[0051] Antioxidant 0.6%;

[0052] Lubricant 0.4%;

[0053] Put all the raw materials together into a high-speed mixer and mix for 2-5 minutes, and discharge; then put the mixed material into a twin-screw extruder to extrude and granulate to obtain a polypropylene composite material with good appearance. Wherein, the process temperature is 180° C., and the screw speed is 350 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com