Sleeving method between steel wire rope and molten metal

A technology of molten metal and steel wire rope, which is applied in the field of steel wire rope molten metal socketing and steel wire rope socketing, which can solve the problems of low strength and achieve the effect of eliminating grease, simple and easy socketing method, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be explained in detail below in conjunction with the accompanying drawings.

[0023] A steel wire rope molten metal socketing method according to an embodiment of the present invention comprises the following steps:

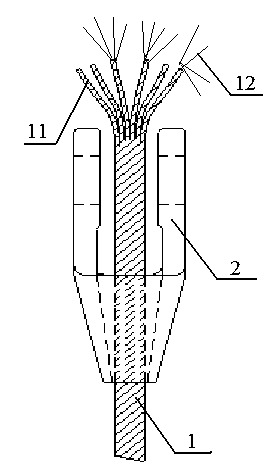

[0024] Step 1, such as figure 1 Pass one end of the wire rope 1 through the joint 2 as shown in . Steel wire rope 1 is made up of rope strand 11, and rope strand 11 is made up of steel wire 12;

[0025] Step 2, opening the strand 11 and the steel wire 12 at one end of the steel wire rope 1 passing through the joint 2 in sequence;

[0026] Step 3, cold-bending and degreasing the steel wire 12;

[0027] Step 4, insert the cold-bent steel wire 12 into the joint 2 and add metal to form the sling.

[0028] The steel wire rope molten metal sheathing method of the present invention is simple and easy to implement, effectively eliminates the grease of the steel wire rope, makes the steel wire rope fully connected with the molten meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com