Shield machine starting device with adjustable seal

A shield machine and adjustable technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as massive water gushing, gushing, and subsidence, and achieve the effects of enhancing sealing capabilities, reducing construction risks, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

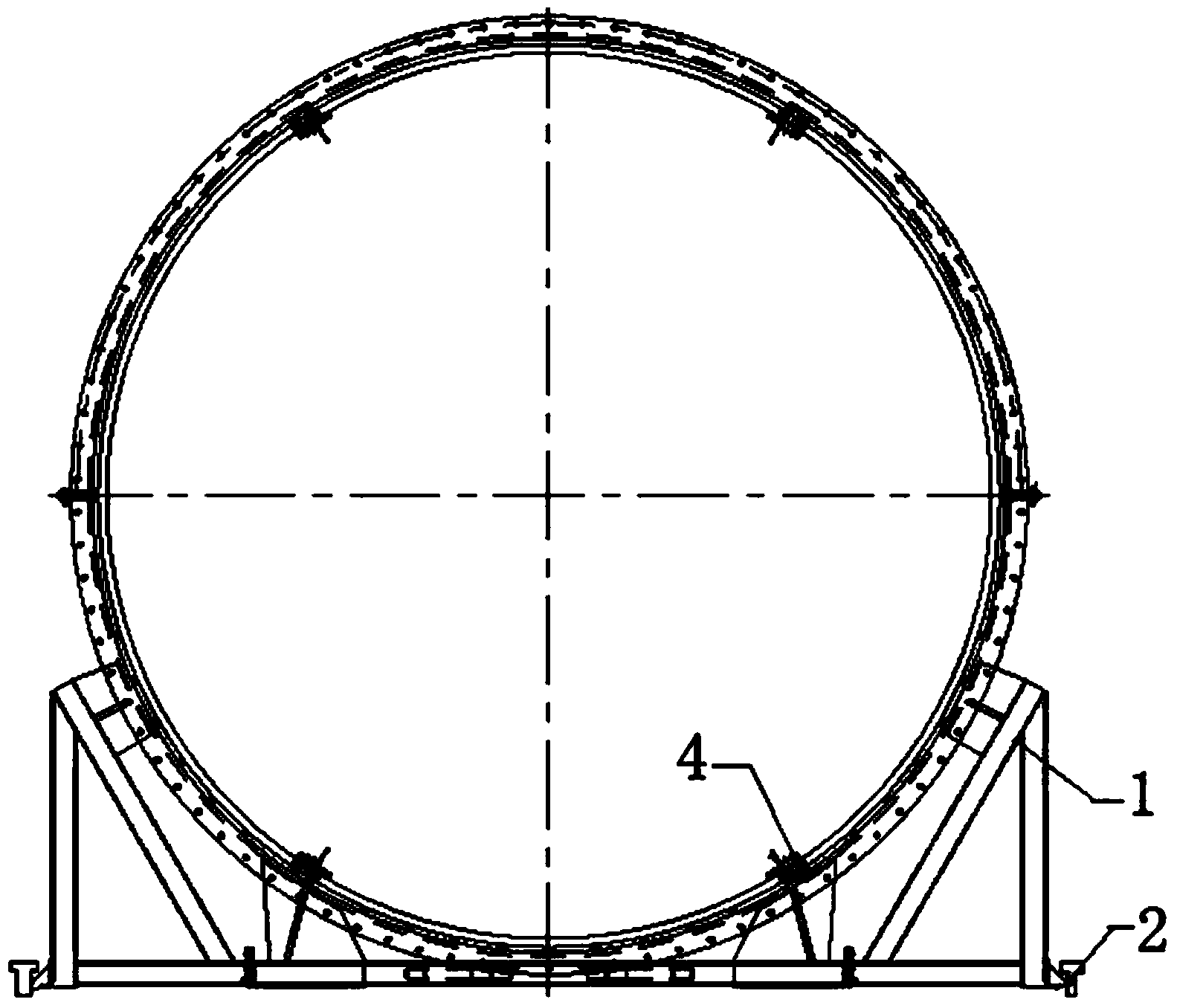

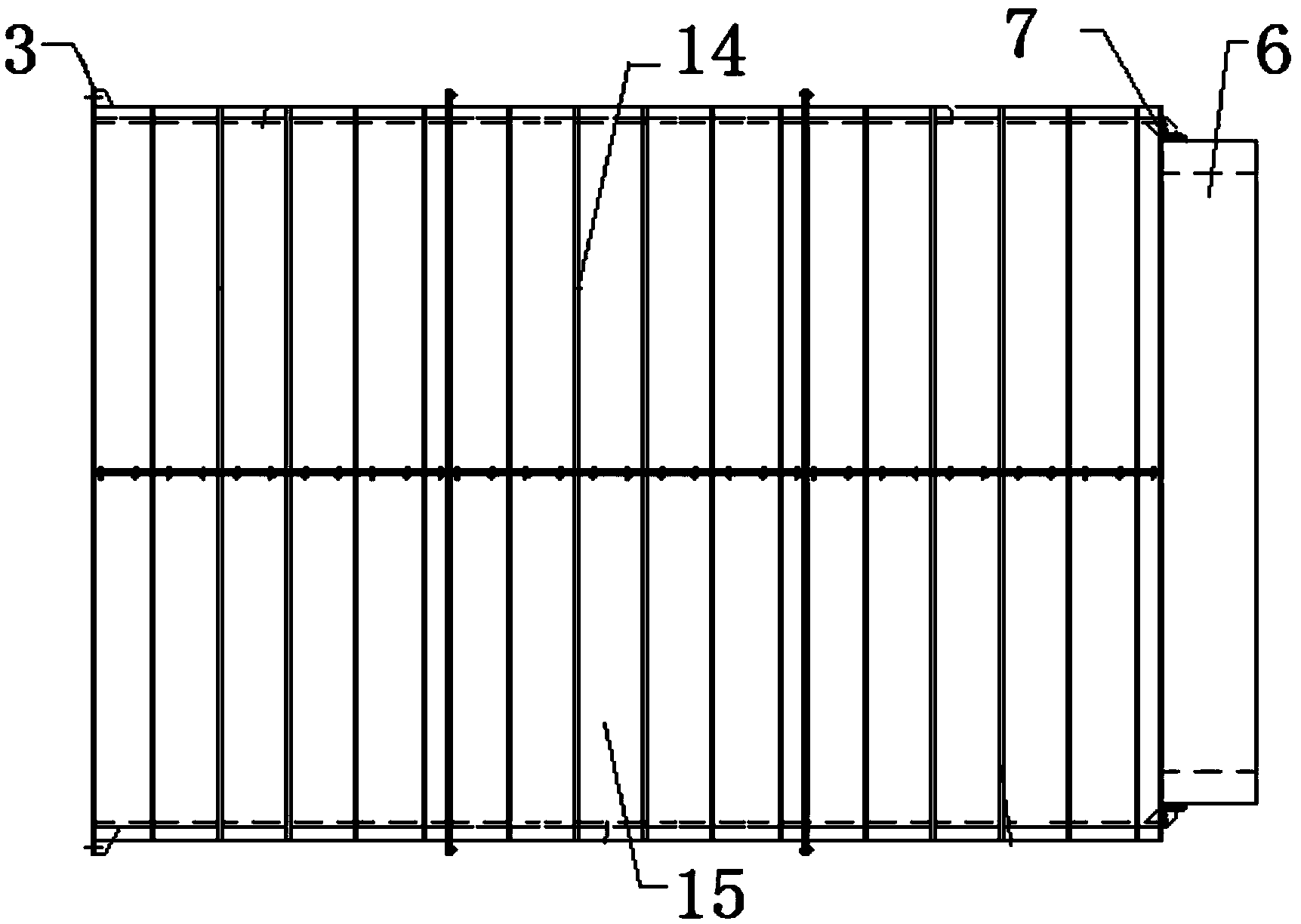

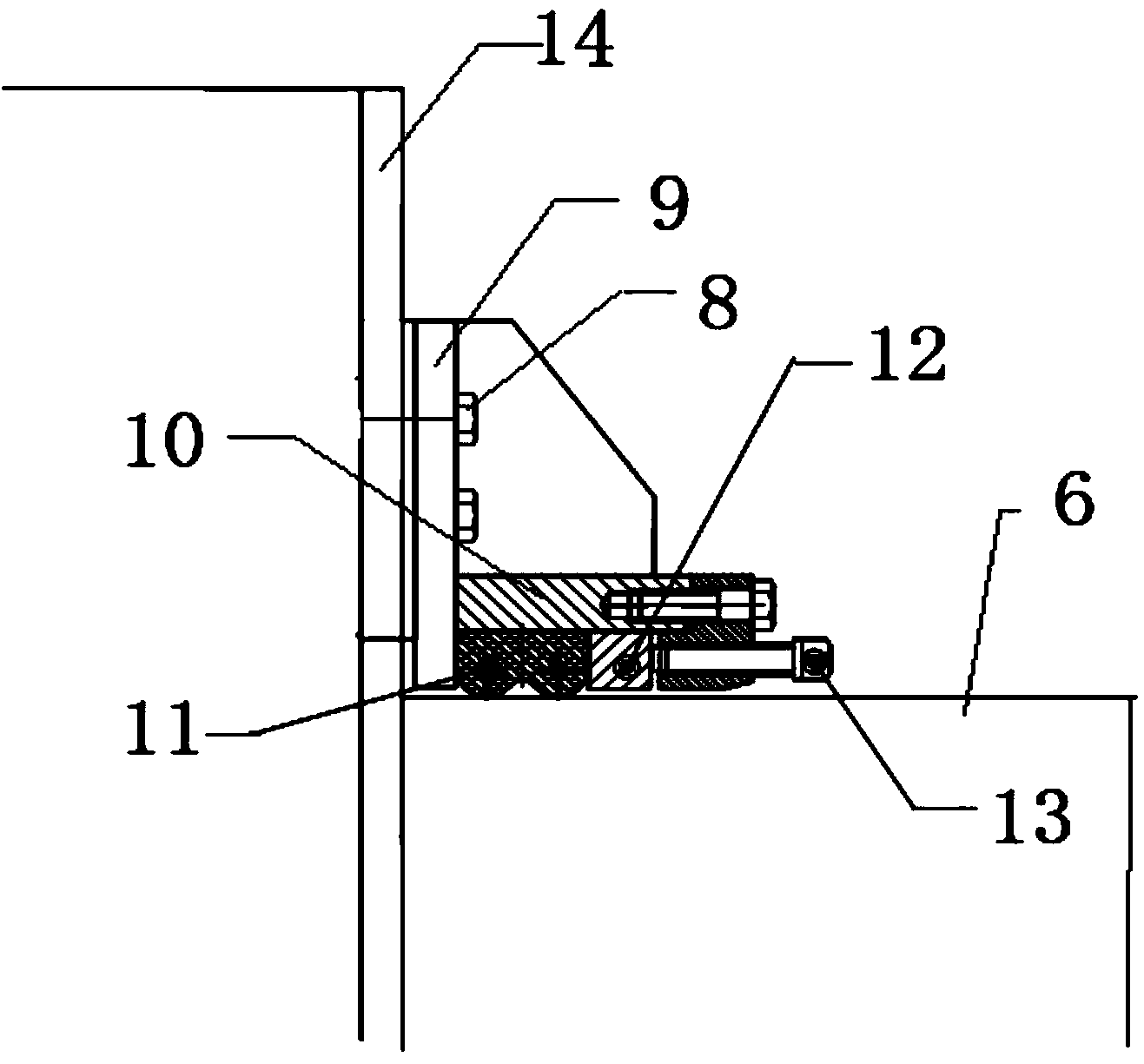

[0016] Such as Figure 1 to Figure 4 As shown, the launching device of the shield machine equipped with adjustable seals according to the present invention includes an underframe 1 on which a cylinder is arranged, and both sides of the underframe 1 are provided with pre-embedded steel plate connecting plates for the launching shaft. The connecting plate of the pre-embedded steel plate of the originating shaft can be connected with the pre-embedded steel plate of the originating shaft through the fixing bolt 2, and can be fixed with the pre-embedded steel plate in the originating shaft; The shield machine support device is provided on the surface, and the shield machine support device is used to reduce the friction between the shield body and the cylinder of the shield machine. Positioning groove, the anti-roll positioning groove of the shield machine cooperates with the positioning pin 5 set on the shield machine, and the positioning pin 5 can be pushed out of the shield body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com