Control device and method for low vortex shaft ultrasonic cleaning equipment of aero-engine

An aero-engine, ultrasonic cleaning technology, applied in non-electric variable control, cleaning methods and utensils, cleaning methods using liquids, etc. Such problems as cleaning requirements for similar parts and blisk parts to achieve the effect of improving service life and reliability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] An embodiment of the invention will be further described below in conjunction with the accompanying drawings.

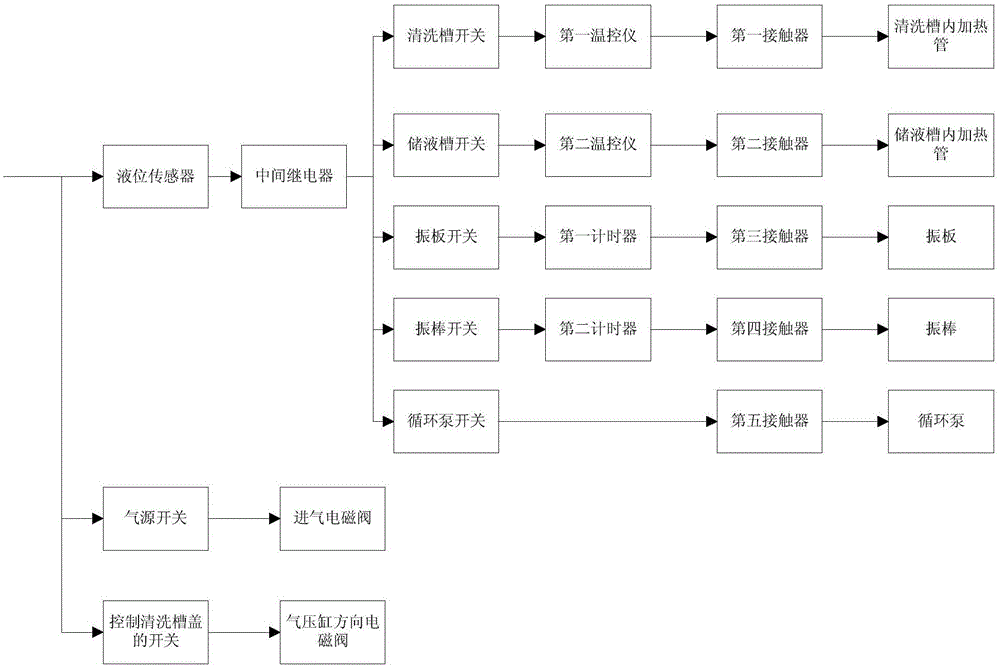

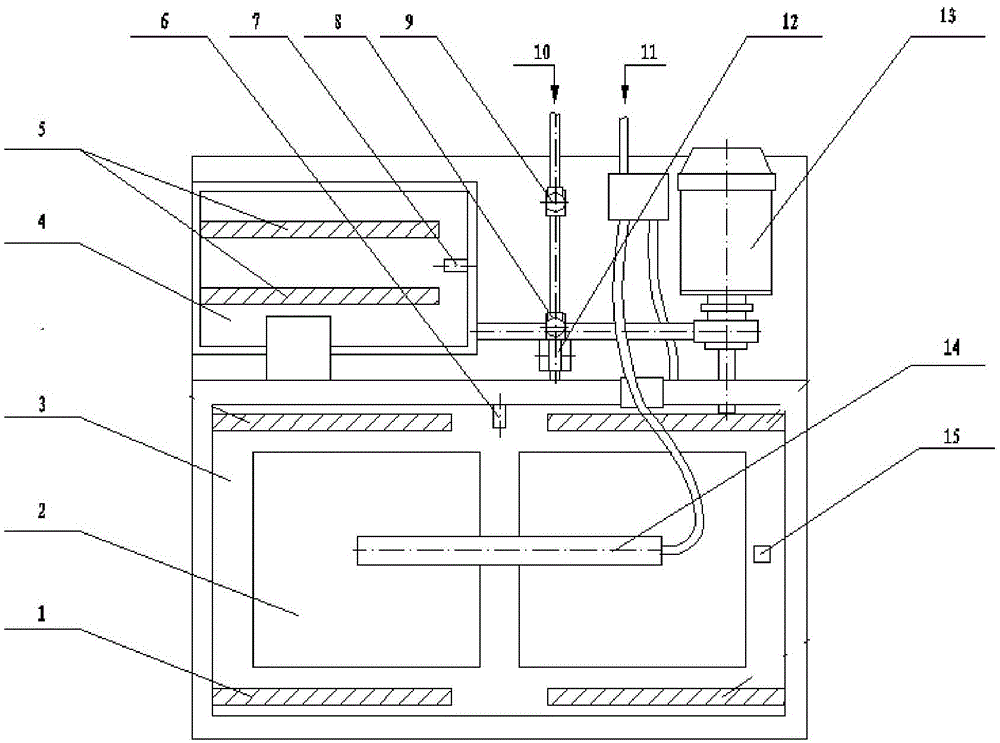

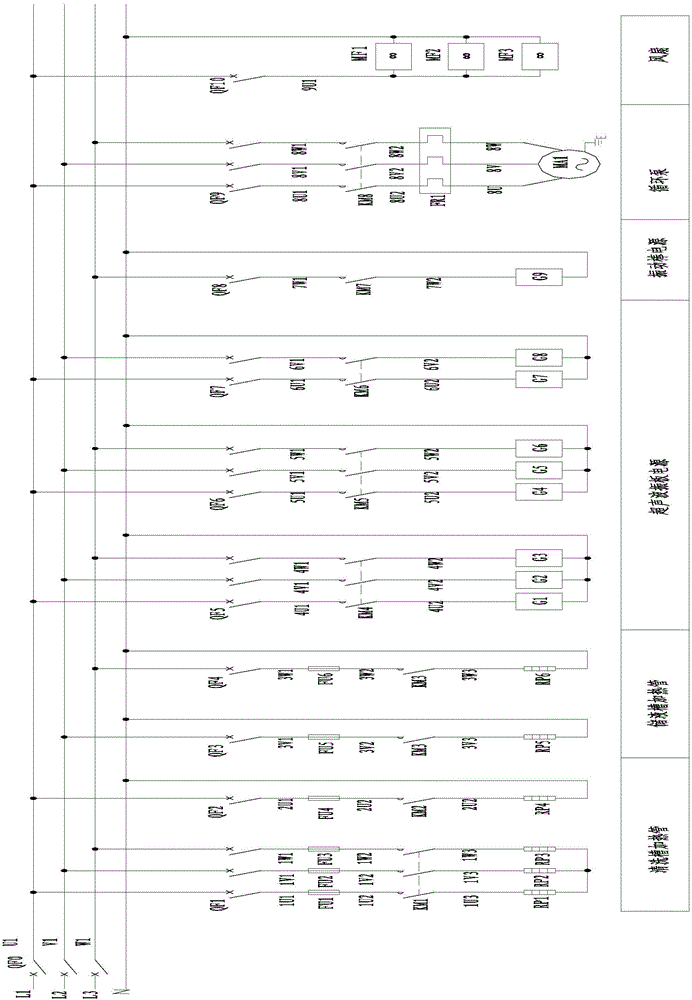

[0030] Such as figure 1 As shown, a control device for an aero-engine low vortex ultrasonic cleaning equipment includes a liquid level sensor, an intermediate relay, a first temperature controller, a second temperature controller, a first temperature sensor, a second temperature sensor, a first timer timer, second timer, first contactor, second contactor, third contactor, fourth contactor, fifth contactor, intake solenoid valve, pneumatic cylinder direction solenoid valve, cleaning tank switch, liquid storage tank Switches, vibrating plate switches, vibrating rod switches, circulating pump switches, gas source switches and switches used to control the cleaning tank cover; in the embodiment of the present invention, the liquid level sensor adopts the 0KD-1075S model; the intermediate relay adopts the RY4S-U model; The cleaning tank switch, liquid storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com