Operating mechanism of miniature circuit breaker

A technology of a small circuit breaker and an operating mechanism, which is applied in the field of components of circuit breakers, can solve the problems of easy falling, short service life, inconvenient maintenance, etc., and achieves the effects of low position accuracy requirements, reduced friction, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

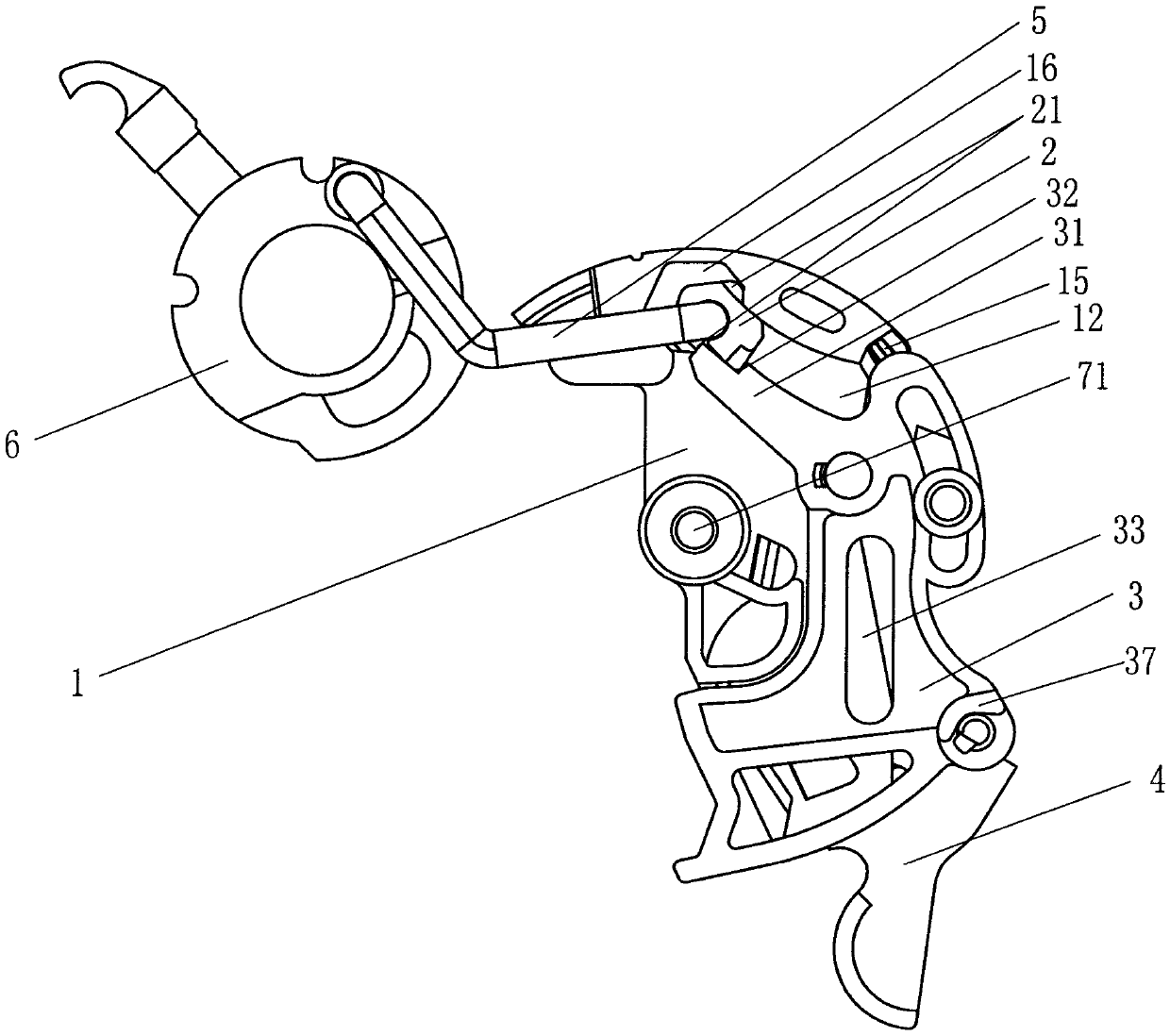

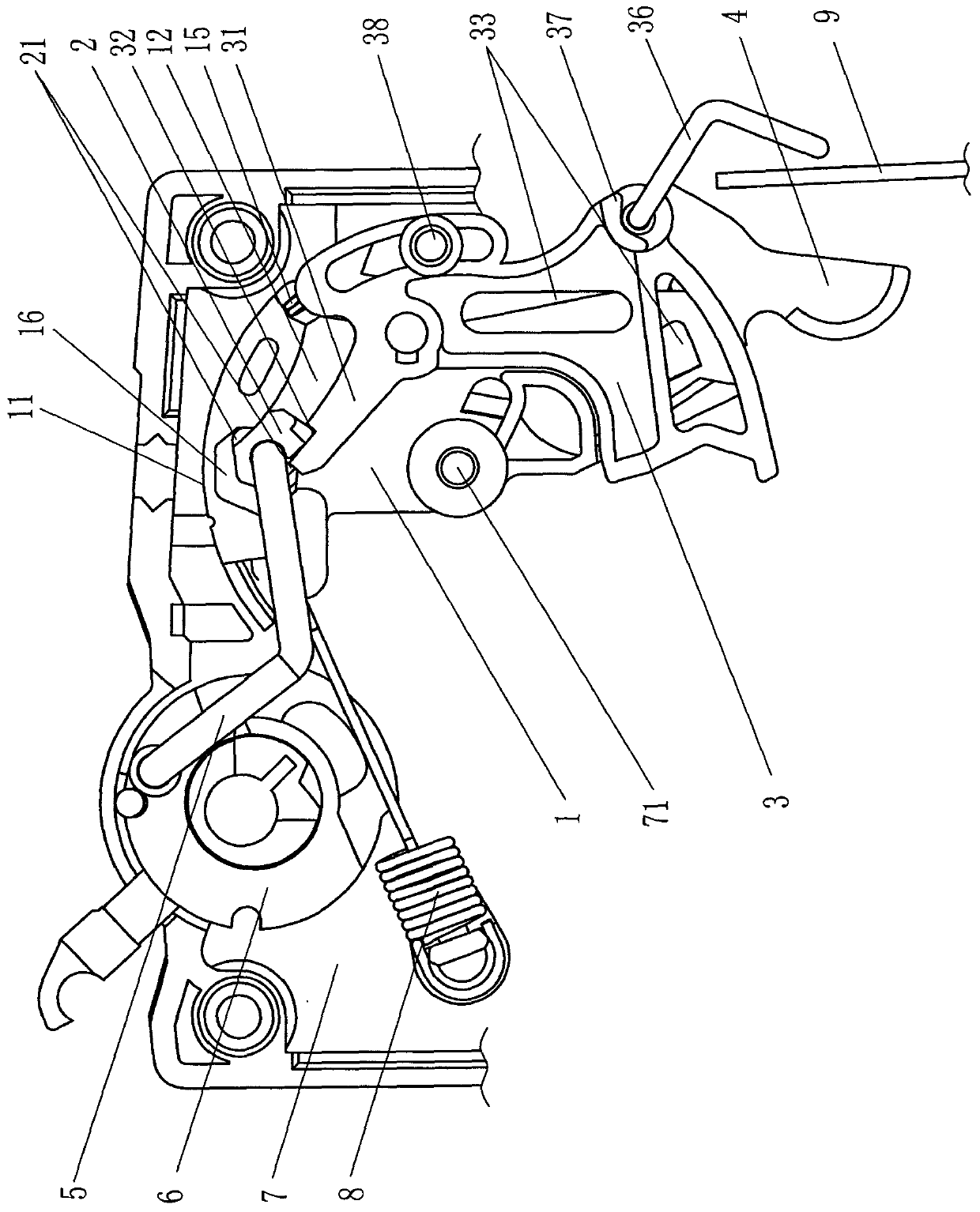

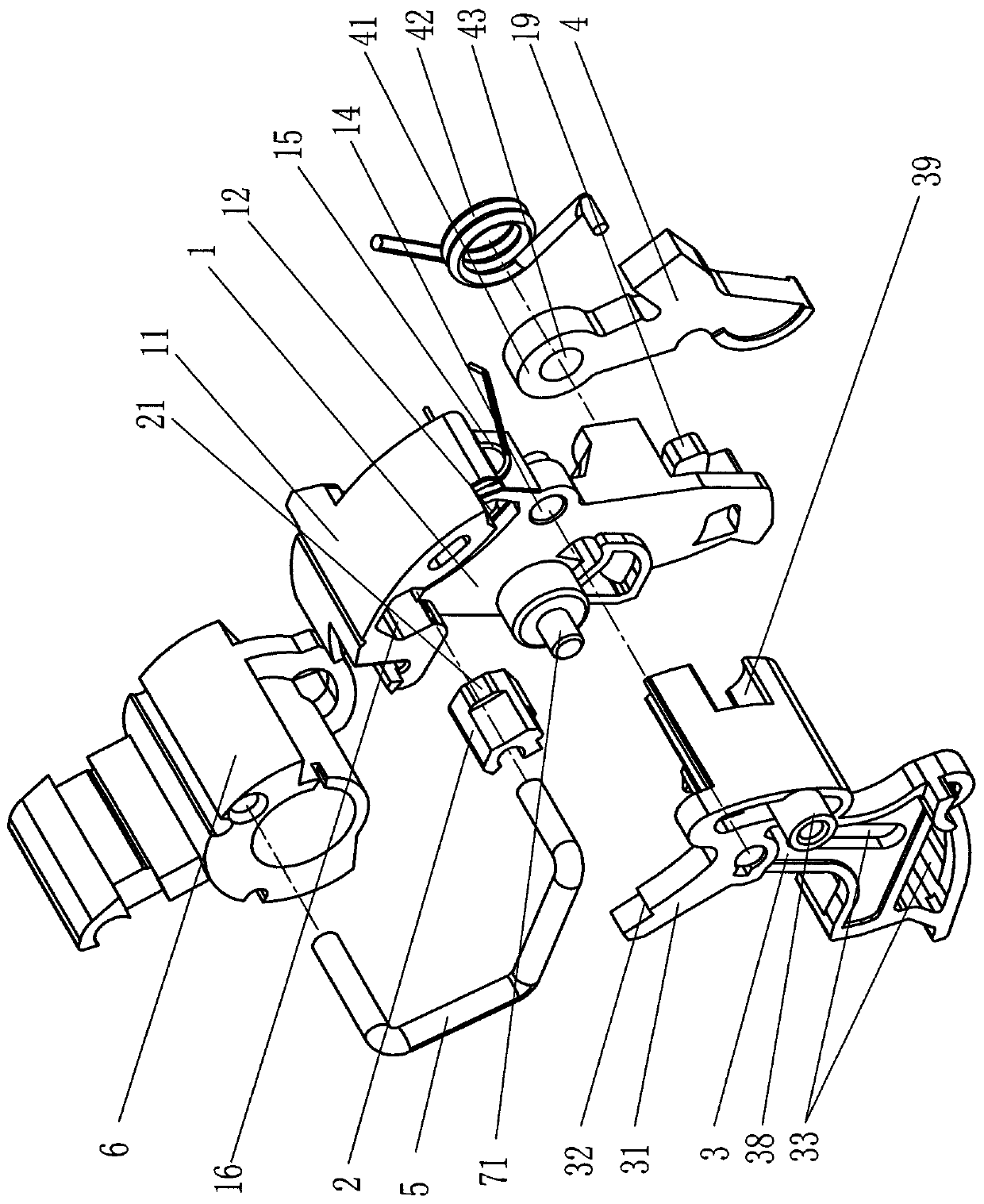

[0022] Such as Figure 1-7 As shown, the embodiment of the present invention is an operating mechanism of a small circuit breaker, including a contact bracket 1, a jumper 2, a lock 3, a moving contact 4, a U-shaped rod 5, a handle 6, and the upper end of the contact bracket 1 A switch indicating surface 11 is formed, a central hole is formed on the inner side of the middle part of the contact bracket 1, and a central shaft 71 for being hinged on the circuit breaker housing 7 is inserted in the central hole. The other end is connected on the shell 7. The upper part of the contact bracket 1 forms an arc-shaped jumper groove 12, the upper side of the jumper 2 is an arc surface 23 that matches the upper groove wall of the jumper groove 12, and the groove wall of the jumper groove 12 forms a limiting groove 13. The jumper groove 13 on the upper side wall of the jumper is close to the handle 6 to form a jumper installation position 16 suitable for the maximum cross-sectional area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com