Polygonal packaging box

A packaging box and polygonal technology, applied in the field of packaging boxes, can solve the problems of low mechanical strength, small shock resistance, and increased transportation costs, and achieve the effects of dark storage, reduced use costs, and convenient display of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

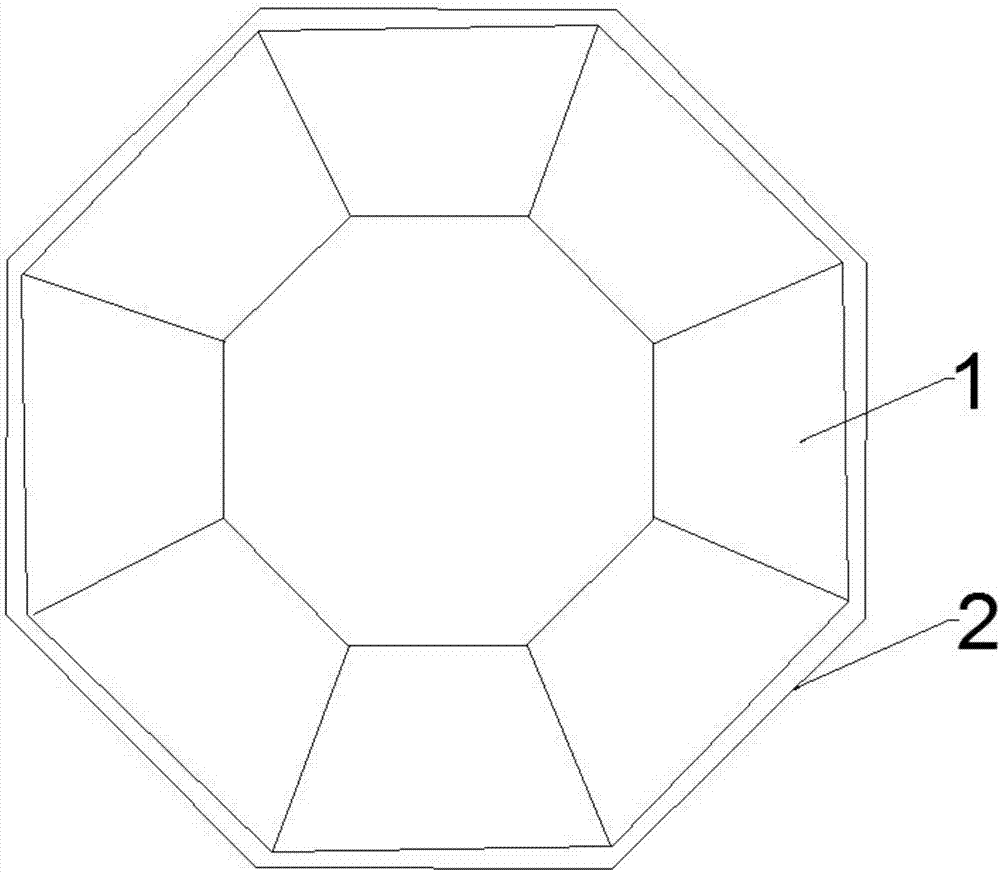

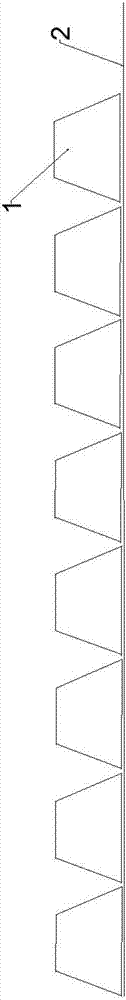

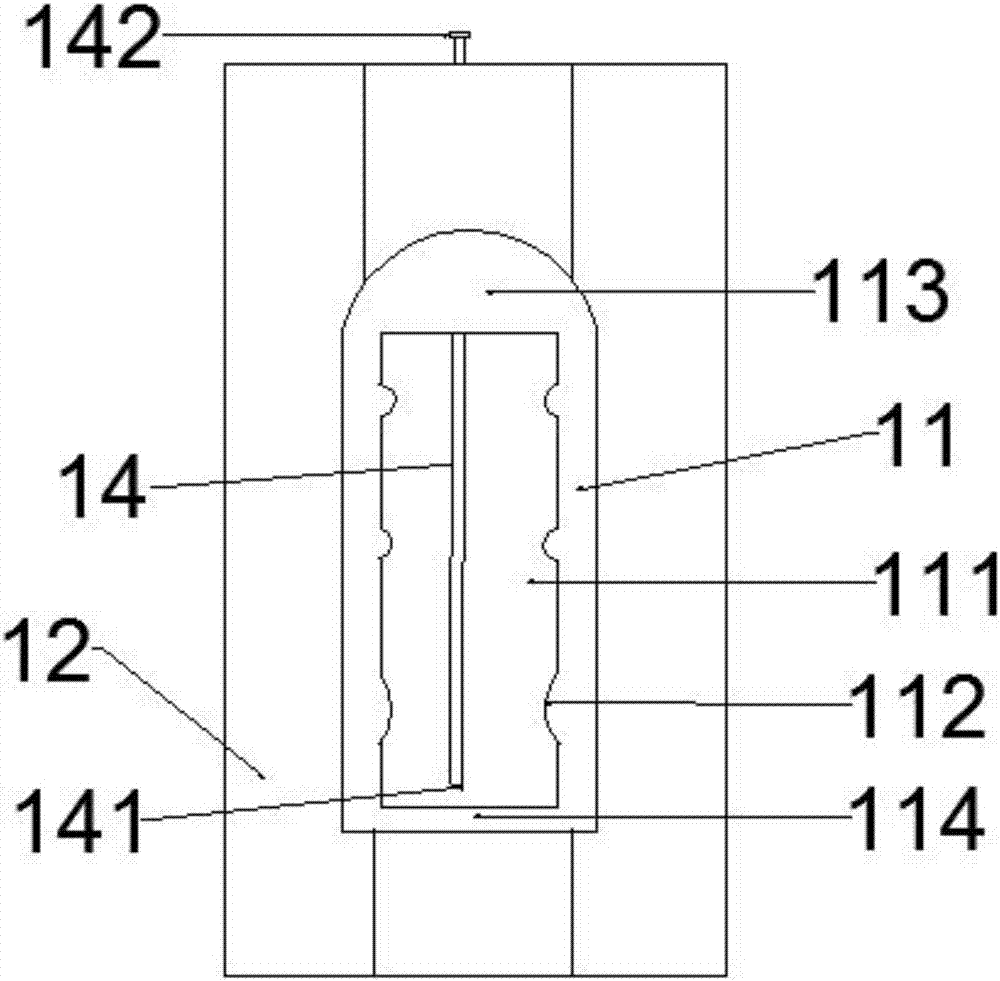

[0036] Such as Figures 1 to 3 As shown, a polygonal packaging box includes a small box body 1 and a connecting piece 2 . The small box body 1 includes a fixing part 11 and an outer cavity 12 surrounded by cardboard. The top and bottom of the outer cavity 12 are both trapezoidal; ; The fixing member 11 is provided with an inner cavity 111 for fixing the product, and the side wall of the inner cavity 111 is provided with a limiting body that can produce elastic deformation. The limiting body can not only fix the product, but also play a buffering role. When the packaging box encounters severe vibrations, the products are not easy to collide with each other and cause damage; the fixing part 11 is provided with a semicircular structure 113 near the upper part of the inner cavity 111, which is convenient for taking the product and will not draw fingers; the fixing part 11 is close to the inner cavity The part below the body 111 is provided with a platform structure 114, which is ...

Embodiment 2

[0038] As shown in Embodiment 1, the only difference is that a lifting column 3 is also included. When the adsorption body 21 arranged on the connecting sheet 2 is overlapped, a cavity is formed in the middle of the packaging box due to the gathering of the small box body 1; as Figure 5 As shown, the top of the lifting column 3 is provided with a handle 31 passing through the cavity, and the bottom end is provided with a chassis 32, the area of the chassis 32 is larger than the area of the cavity, so that the lifting column 3 can lift the polygonal packaging box. The height of the lifting column 3 is equal to the width of the connecting piece 2, and the packaging boxes are not easily deformed when stacked up and down during loading and transportation.

Embodiment 3

[0040] As shown in Embodiment 2, the only difference is that a guide hole 13 is provided on the top of the small box body 1, which communicates with the inner cavity 111 of the fixing member 11; The diameter of the guide hole 13 ranges from 0.5 to 1.0 cm. When displaying samples, a sample bottle with a conduit 14 can be placed in the inner cavity 111 of the fixture 11. When customers try it out, they can directly take a small amount of products through the conduit 14, which is convenient and can meet special products, especially essential oils. Requirements for storage away from light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com