Large-capacity pulse type power lithium-ion battery and preparation method thereof

A lithium-ion battery, pulse-type technology, applied in the field of lithium-ion batteries, can solve the problems of affecting battery life, low energy density, battery damage, etc., to achieve improved energy storage capacity, high energy density and power density, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

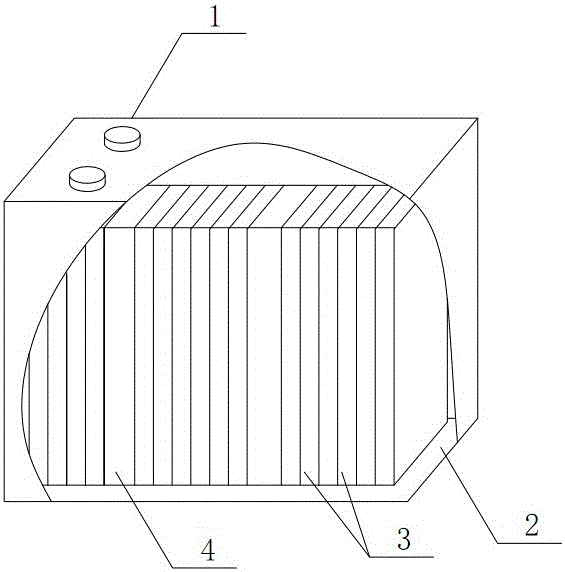

[0041] A large-capacity pulse-type power lithium ion battery, comprising a casing 1, a battery core, and an electrolyte 2 contained in the casing 1. The battery core includes a plurality of lithium battery electrodes 3, and the battery core also includes an electric double layer adsorption electrode 4. The electric double layer adsorption electrode 4 is inserted between the lithium battery electrodes 3 at intervals.

[0042] The battery of the present invention is further explained as: an electric double layer adsorption electrode 4 is inserted every 5-15 lithium battery electrodes 3.

[0043] The battery of the present invention is further explained as: the lithium battery electrode 3 and the electric double layer adsorption electrode 4 are connected in parallel.

[0044] The battery of the present invention is further explained as: the lithium battery electrode 3 and the electric double layer adsorption electrode 4 include positive and negative substrates, and the slurry coated on ...

preparation example 1

[0048] (1) Preparation of lithium ion electrode slurry:

[0049] The weight composition of the positive electrode slurry: 90% lithium iron phosphate, 2.5% super-P, 1% sodium hydroxymethyl cellulose, 6.5% styrene butadiene rubber;

[0050] The weight composition of the negative electrode slurry: graphite 92%, super-P 1%, sodium hydroxymethyl cellulose 1% and styrene butadiene rubber 6%;

[0051] (2) Preparation of electric double layer adsorption electrode slurry

[0052] The weight composition of the positive electrode slurry: 90% three-dimensional layered porous carbon, 0.5% multi-walled carbon nanotubes, 1.5% sodium hydroxymethyl cellulose and 8% styrene butadiene rubber;

[0053] The weight composition of the negative electrode slurry: three-dimensional layered porous carbon 85%, KS-6 graphite 10%, sodium hydroxymethyl cellulose 1.0%, styrene butadiene rubber 4.0%;

[0054] (3) Sheet making: transfer the prepared positive and negative slurry to the positive and negative substrates wit...

preparation example 2

[0060] (1) Preparation of lithium ion electrode slurry:

[0061] The weight composition of the positive electrode slurry: 93% lithium cobaltate, 3% acetylene black, 0.5% sodium hydroxymethyl cellulose, 3.5% styrene butadiene rubber;

[0062] The weight composition of the negative electrode slurry: mesocarbon microspheres 96%, super-P 1%, sodium hydroxymethyl cellulose 0.5% and styrene butadiene rubber 2.5%;

[0063] (2) Preparation of electric double layer adsorption electrode slurry

[0064] The weight composition of the positive electrode slurry: 93% three-dimensional hierarchical porous carbon, 2% multi-walled carbon nanotubes, 1% sodium hydroxymethyl cellulose and 4% styrene butadiene rubber;

[0065] The weight composition of the negative electrode slurry: 89% three-dimensional layered porous carbon, 8.2% KS-6 graphite, 0.8% sodium hydroxymethyl cellulose, 2.0% styrene butadiene rubber;

[0066] (3) Sheet making: transfer the prepared positive and negative slurry to the positive and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com