Coupling method for vibrating table and shielding box body

A vibrating table and box technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of unsuitable finger reeds and conductive rubber pads, wear of conductive rubber pads, and reduced shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

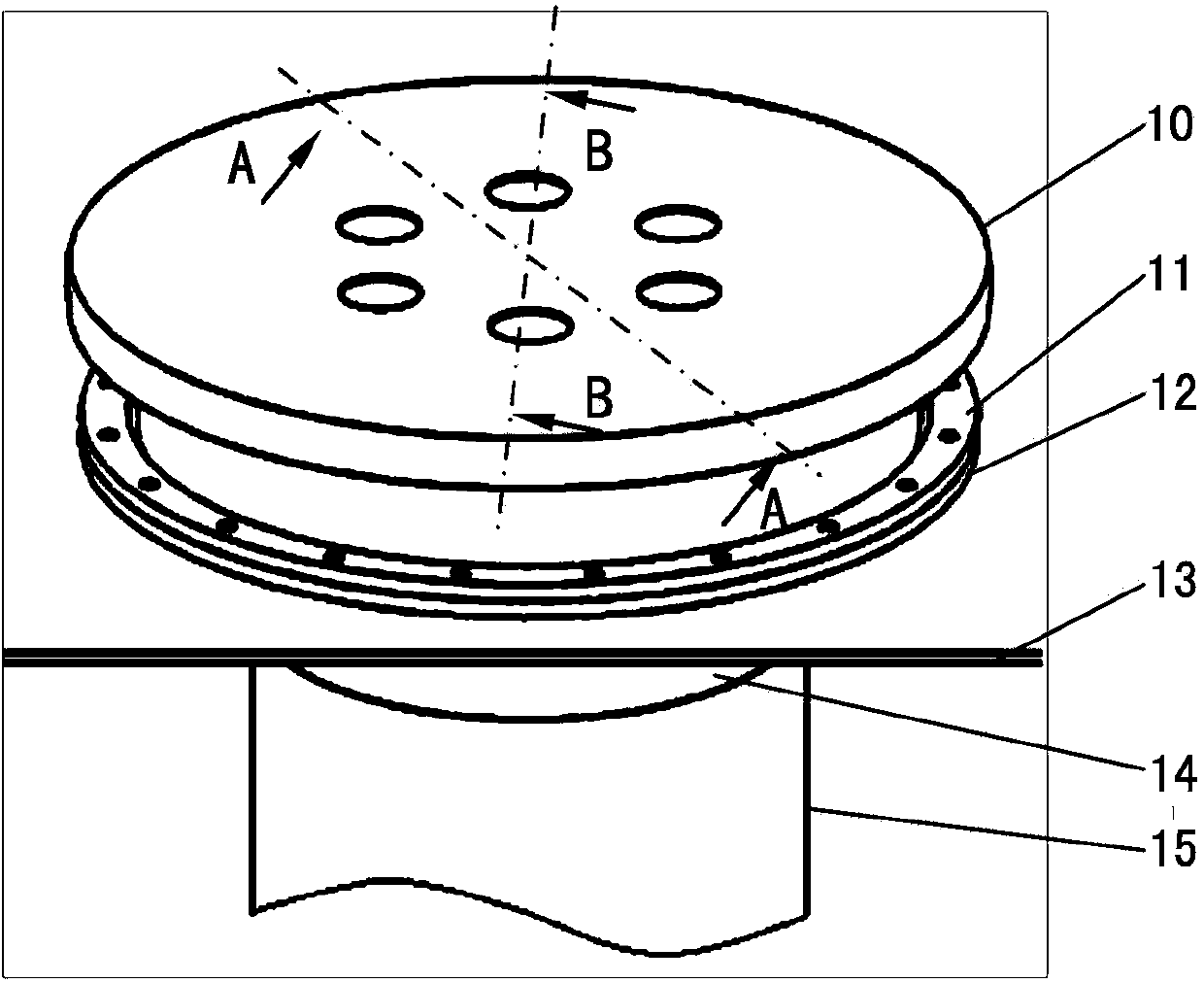

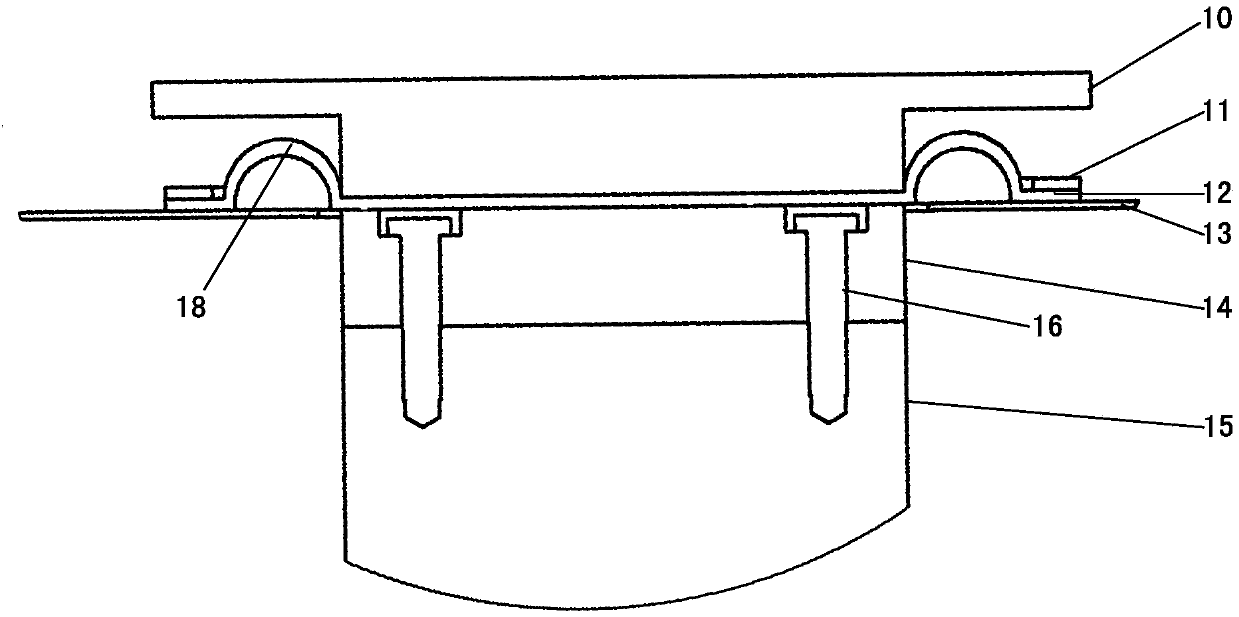

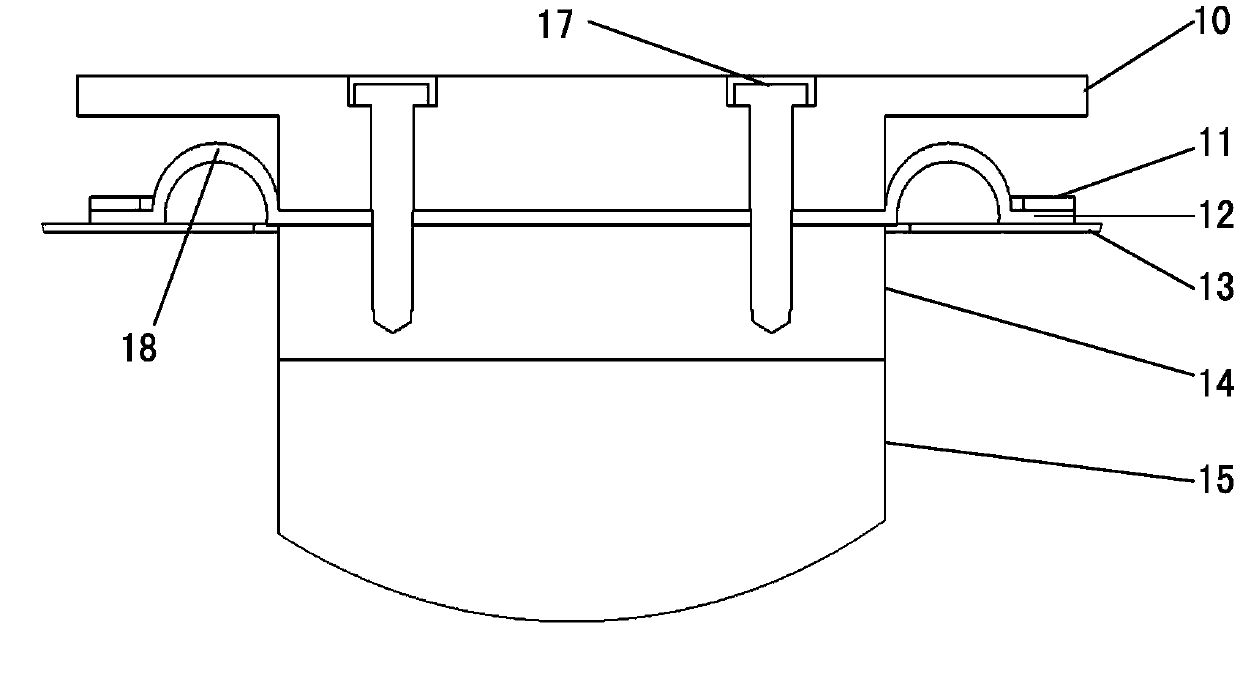

[0035] Such as Figure 1-Figure 3 As shown, holes are opened at the connection between the shielding box 13 and the vibrating table according to the size of the vibrating table moving coil 15, and enough allowance is left to meet the shaking of the vibrating table moving coil 15 in the radial direction; The tooling made of dielectric materials with good mechanical properties is divided into upper and lower parts. The upper part 10 is located inside the shielding box 13 and is used to fix the test piece. The lower half 14 is located outside the shielding box 13 and fixed with bolts 16. On the moving coil 15 of the vibrating table, the upper and lower parts of the frock are connected by bolts 17, and the conductive rubber film 12 is sandwiched between the upper and lower parts of the frock to play a shielding role.

[0036] The conductive rubber film has both sealing and shielding properties, and is an excellent shielding material. However, the elasticity of the conductive rubbe...

Embodiment 2

[0038] On the basis of the above embodiments, further, a method for connecting a vibrating table and a shielding box is provided, including the following steps:

[0039] Step 1: set a hole at the connection between the shielding box 13 and the vibrating table according to the size of the vibrating table moving coil 15, and the opening is also provided with a predetermined margin that can satisfy the shaking of the vibrating table moving coil 15 in the radial direction;

[0040] Step 2: add tooling on the moving coil 15 of the vibrating table, and divide the tooling into an upper part 10 and a lower part 14, the upper part 10 is arranged inside the shielding box 13 for fixing Test piece; the lower half 14 is set and fixed on the vibrating table moving coil 15, and is set outside the shielding box 13;

[0041] Step 3: Arranging a conductive rubber film between the upper half 10 and the lower half 14 for shielding.

[0042] Further, the predetermined margin is 5mm-50mm, preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com