Crowd control barrier

A crowd, barrier technology, applied in the field of said belt-to-spool connection, able to solve problems such as spring damage, disassembly and reassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] best practice

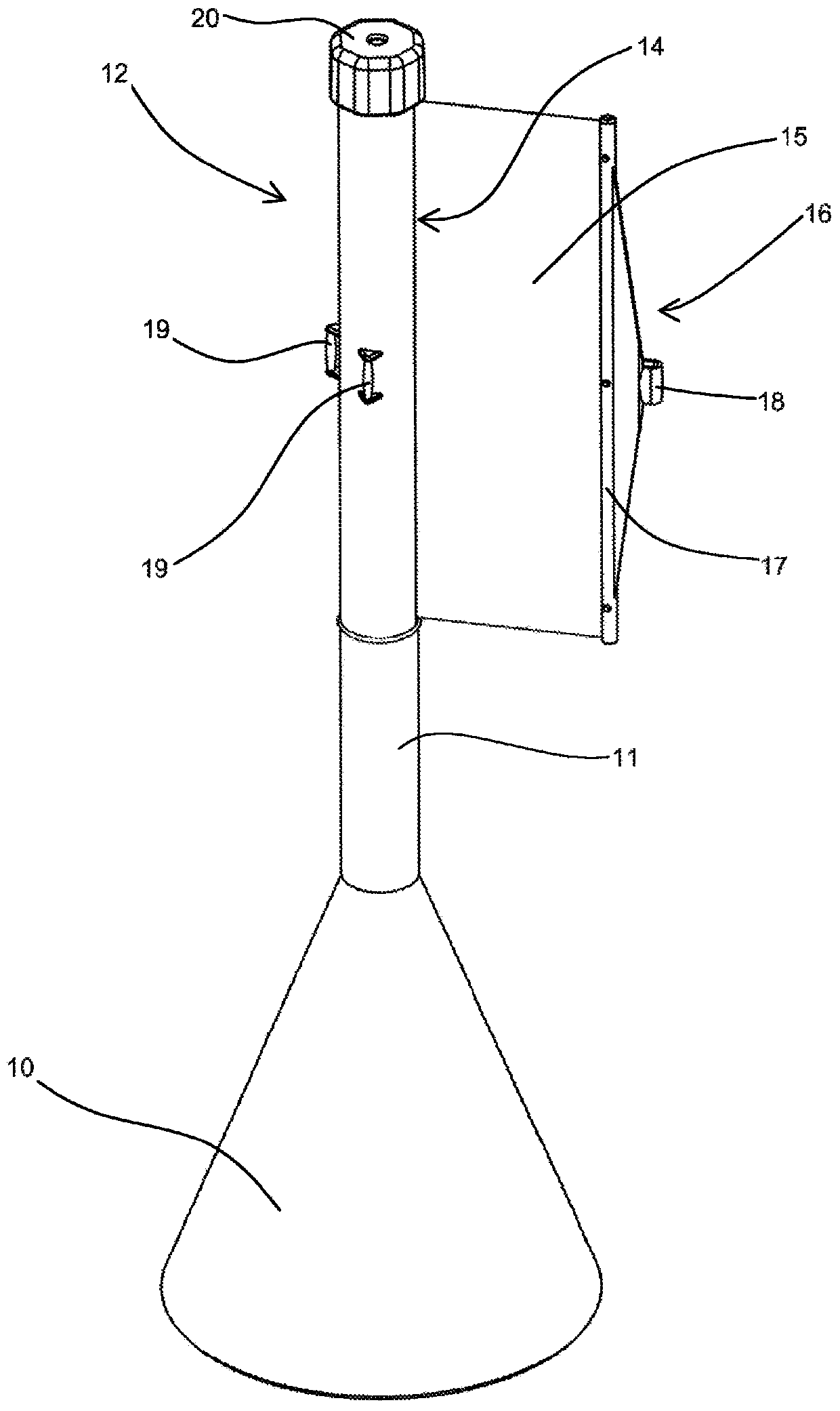

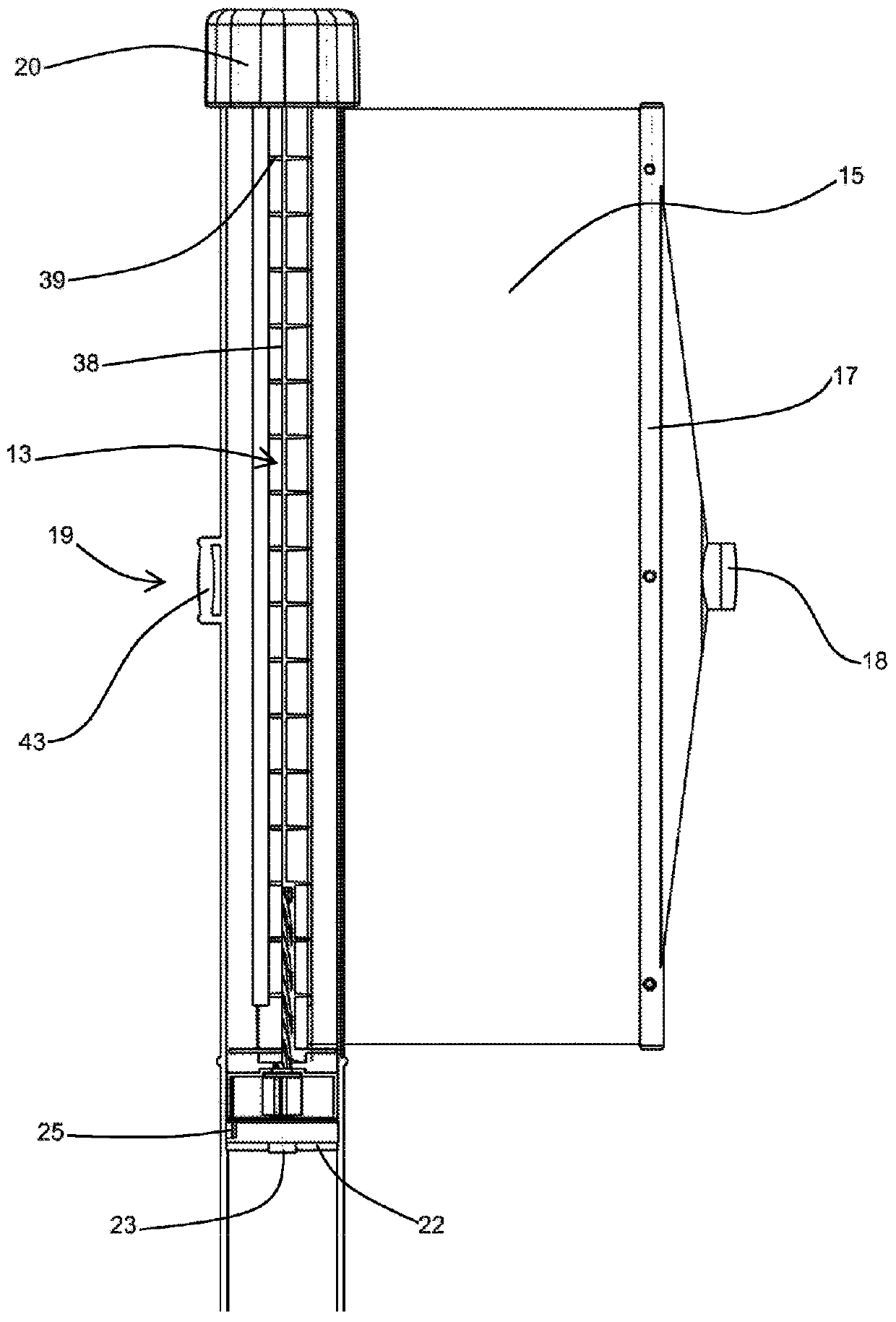

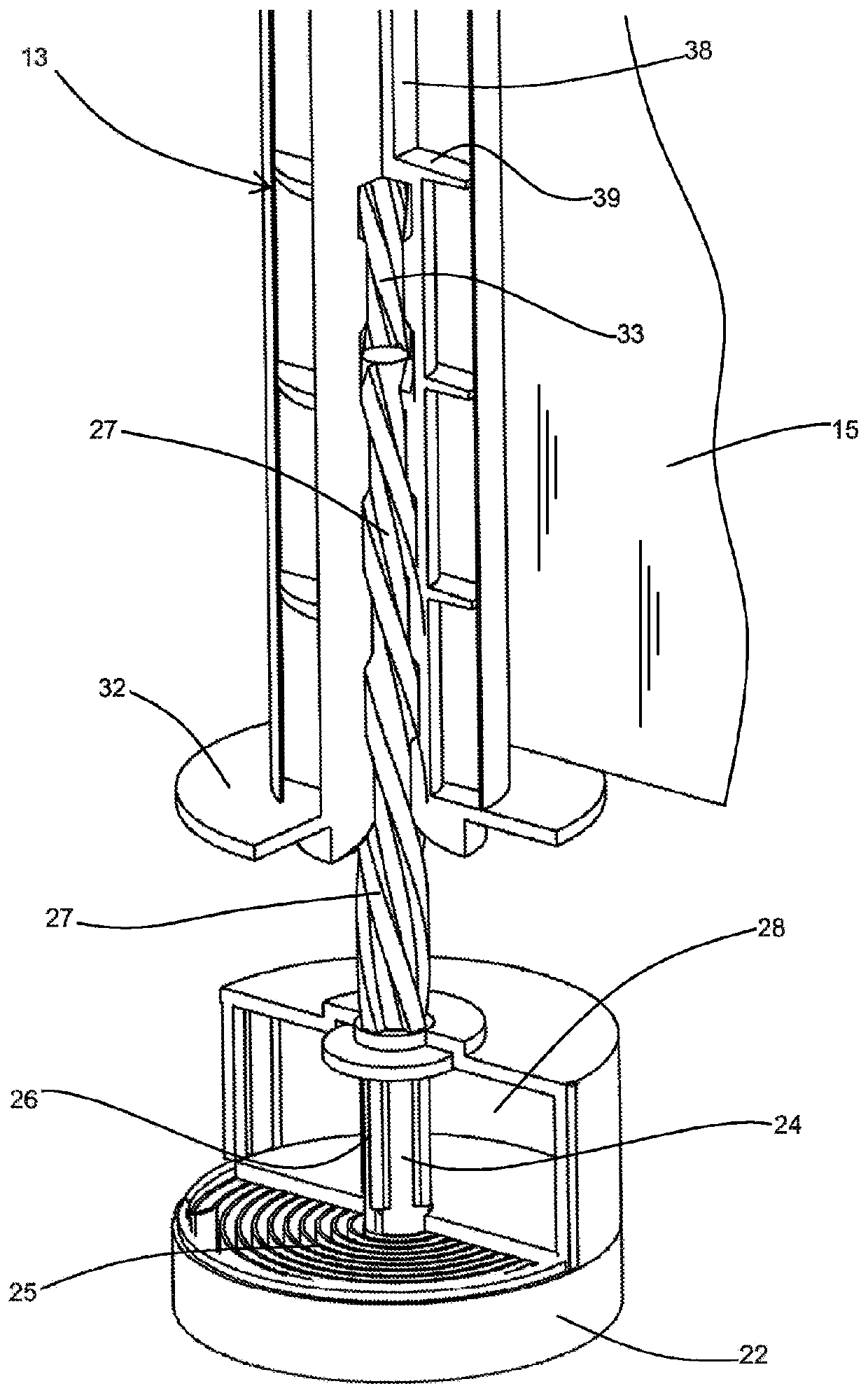

[0034] figure 1 is a general view of an embodiment of a barrier post incorporating aspects of the invention. The column comprises a generally conical base 10 from the top of which a tube 11 protrudes upwards. The upper region 12 of the tube 11 is structured as follows: The holder assembly for the spool 13 ( figure 2 ), an axial slot 14 is formed through the wall of the upper region of the tube, and a tape or film 15 wound on a bobbin 13 may extend through the slot. The free end 16 of the strap 15 is secured to a rod 17, including a clip 18 to allow said rod to be connected to some other support, such as another similar post. For this purpose, three retaining lugs 19 are provided at intervals around the upper region 12 of the tube, to which clips 18 of a strap of another barrier column can be fastened. The open upper end of the upper region 12 of the tube 11 is closed with a cap 20 between which there is a bayonet connection allowing the cap to be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com