Fluid filter

A fluid filter and filter technology, applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance, heavy workload, troublesome disassembly and assembly, etc., to reduce the workload and difficulty, reduce the use of materials, facilitate replacement and cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

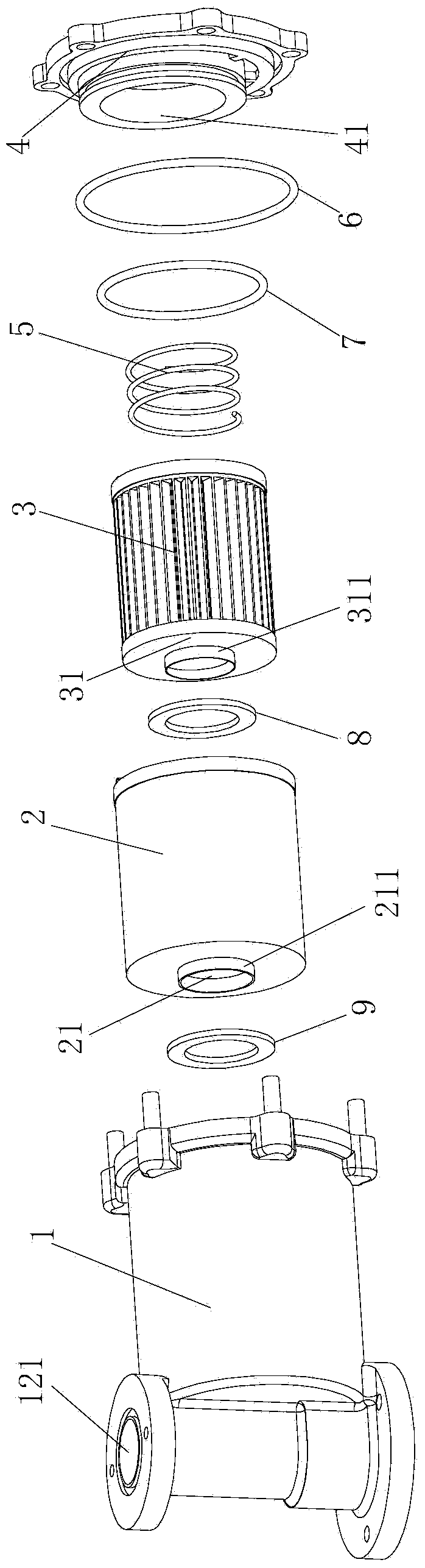

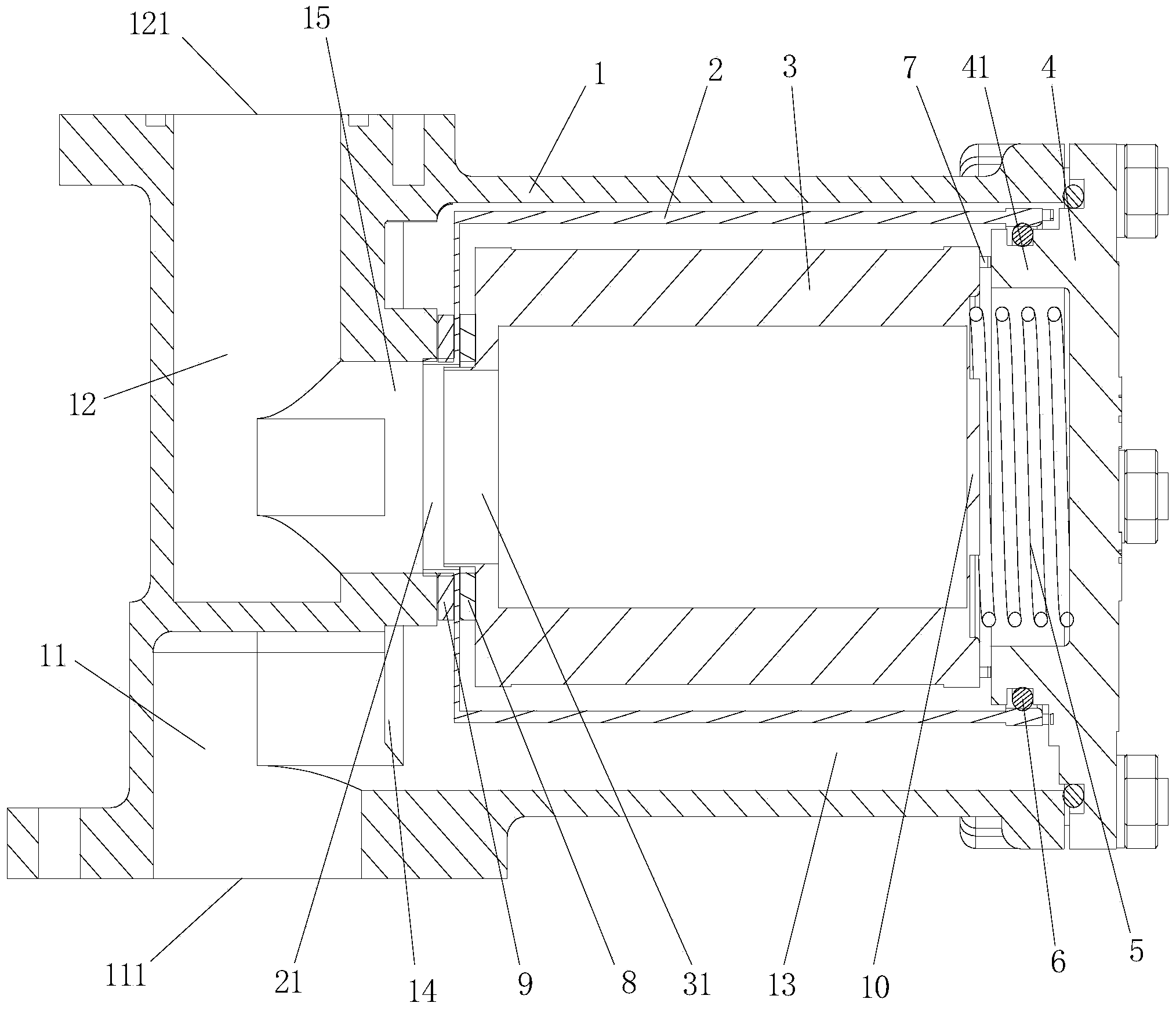

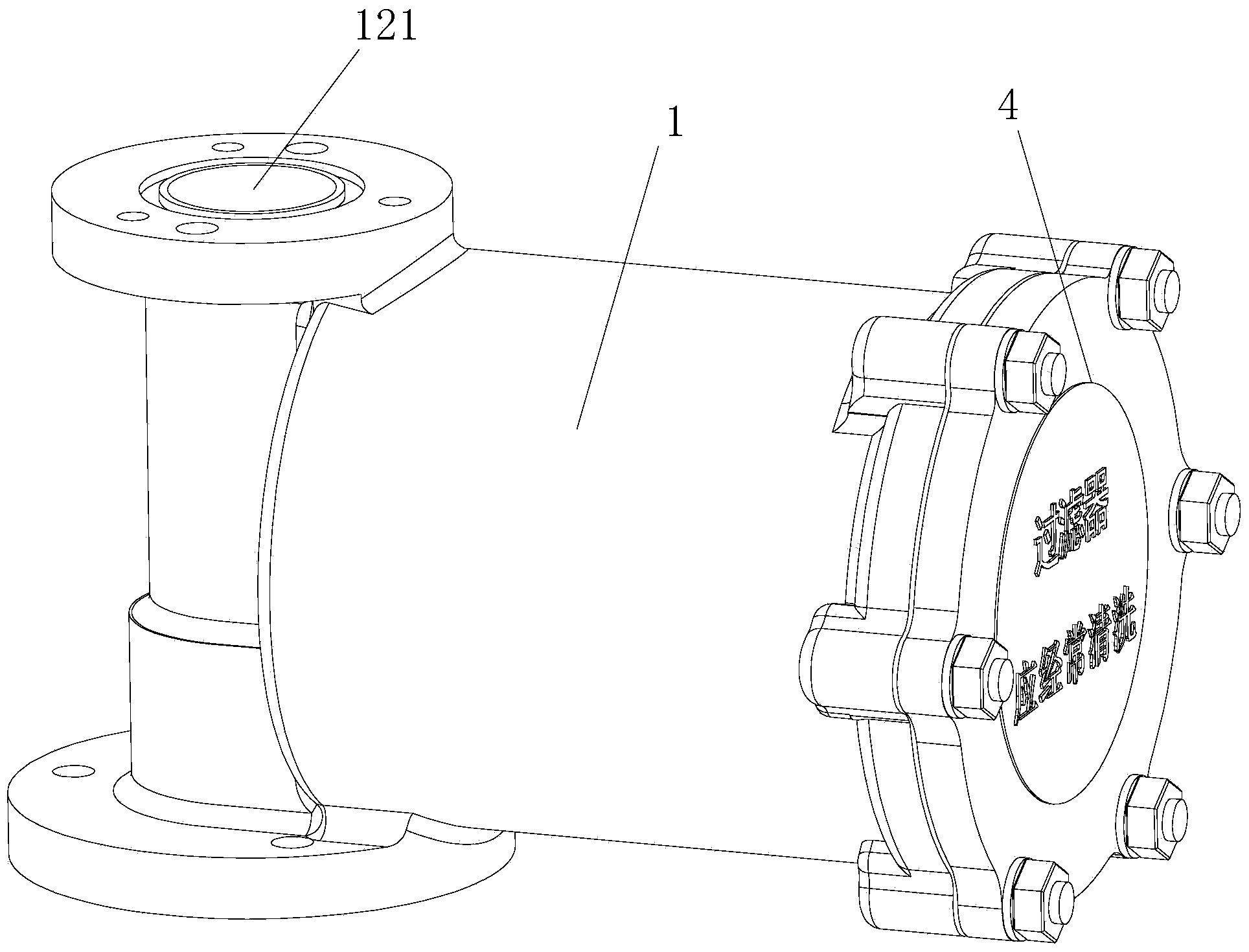

[0026] Such as Figure 1 to Figure 3 A fluid filter shown includes a filter body 1, a primary filter element 2 and a secondary filter element 3, the filter body 1 is provided with an inlet channel 11, an outlet channel 12 and a filter cavity 13, the inlet The channel 11 and the outlet channel 12 are connected through the filter cavity 13 ; the primary filter element 2 is installed in the filter cavity 13 , and the secondary filter element 3 is installed in the primary filter element 2 .

[0027] In order to further reduce the fluid flow, one end of the filter body 1 is provided with a connection port I14 and a connection port II15, the inlet channel 11 communicates with the filter cavity 13 through the connection port I14, and the filter cavity 13 communicates with the filter cavity 13 through the connection port II15. The outlet channel 12 is connected, and the other end of the filter body 1 is provided with an end cover 4; one end of the first-stage filter element 2 is provi...

Embodiment 2

[0037] This fluid filter is the same as Embodiment 1 except the following technical features: the first-stage filter element 2 is a wire mesh filter element, and the second-stage filter element 3 is a water-absorbing filter element. The secondary filter element 3 can be selected according to different requirements of customers. When the secondary filter element 3 is a water-absorbing filter element, the secondary filter element 3 adopts a paper filter element, which has good water absorption effect and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com