Full-automatic high-efficiency ELISA plate washing machine

A fully automatic, plate washer technology, used in drying solid materials, chemical instruments and methods, drying solid materials without heating, etc., can solve the problems of cross infection, the effect is not very good, the efficiency is not too high, etc., to prevent cross Infection, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

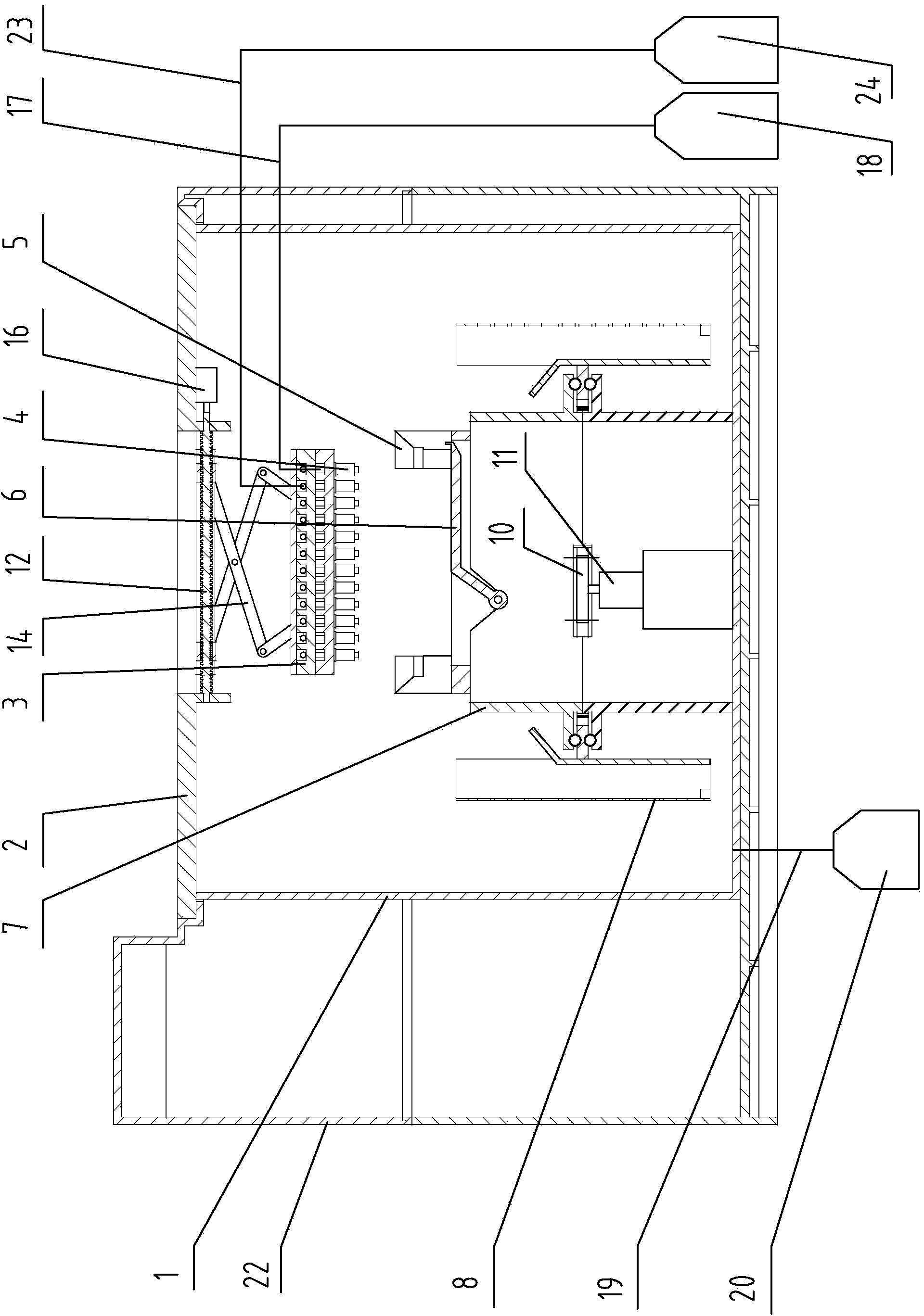

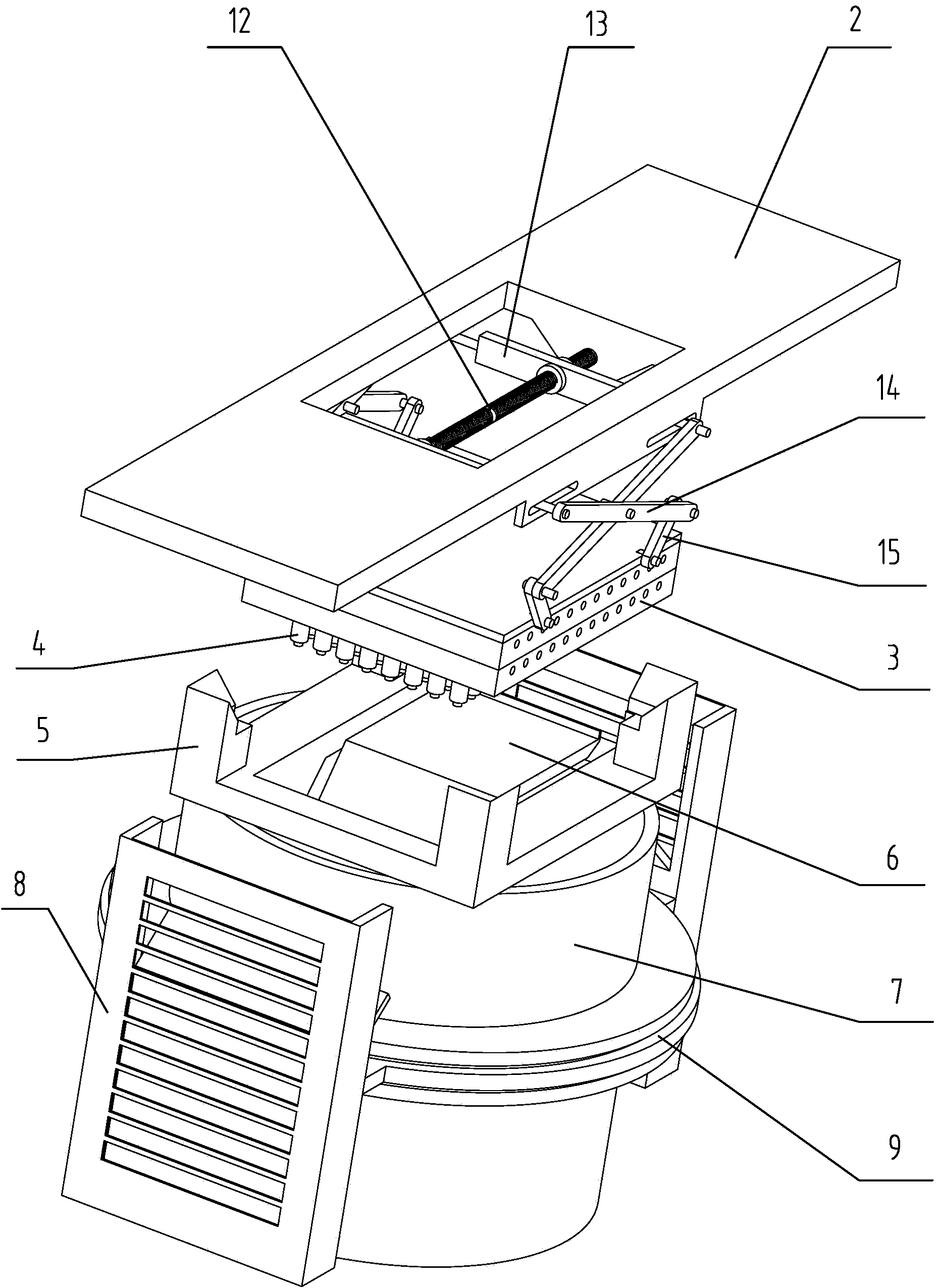

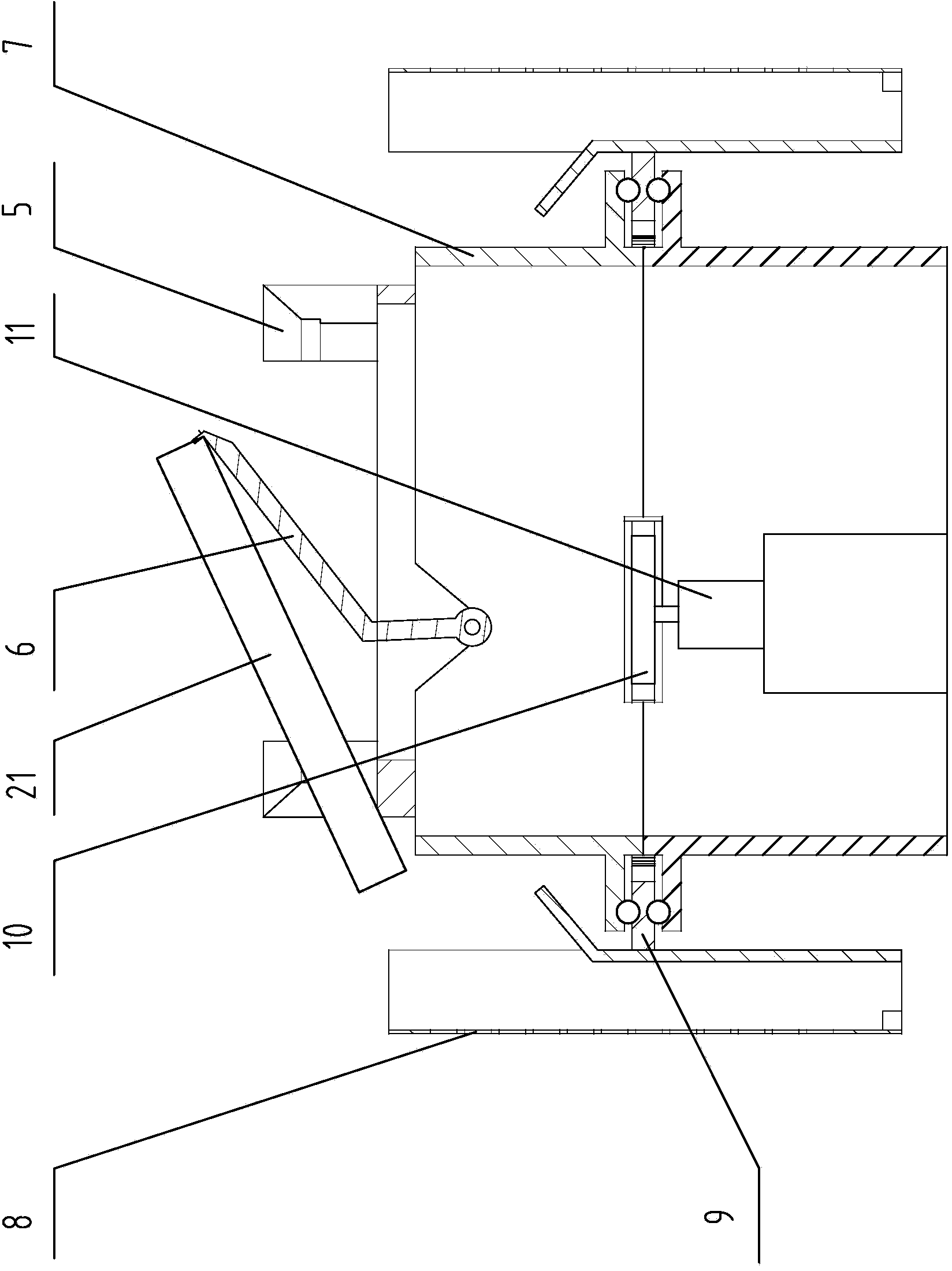

[0023] The technical solutions of the present invention will be further described below with reference to the embodiments shown in the accompanying drawings.

[0024] The fully automatic and high-efficiency enzyme labeling plate washer of the present invention is mainly composed of a barrel 1, a lifting device, a cleaning device, a supporting and transferring device for the enzyme labeling plate and a dehydrating device.

[0025] The barrel 1 is installed on the outer shell 22 , and the lifting device, the cleaning device, the microplate support and transfer device and the dehydration device are arranged in the barrel 1 from top to bottom.

[0026] like figure 1 , figure 2 As shown, the lifting device includes a square hanging plate 2 and a lifting mechanism, the hanging plate 2 is arranged on the barrel mouth of the barrel 1 , and the lifting mechanism is installed at the bottom of the hanging plate 2 .

[0027] The lifting mechanism is composed of a screw rod 12, a moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com