Heating kiln for restoring polluted soil

A technology for polluting soil and heating kiln, applied in the field of heating kiln, can solve the problems of soil loss and easily damaged soil properties, and achieve the effects of uniform heating, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

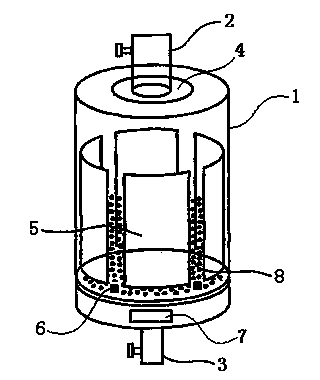

[0012] Reference figure 1 As shown, a heating kiln for remediation of contaminated soil includes a kiln body 1. One end of the kiln body 1 is provided with a feed port 2 and the other end is provided with a discharge port 3, and contaminated soil 8 enters the plant through the feed port. Inside the kiln body 1, the inlet 2 and the outlet 3 are arranged on the end surface of the kiln body 1 to rotate through a rotary bearing 4, and the inner side wall of the kiln body 1 is evenly provided with With four heating tiles 5, four temperature sensors 6 are evenly distributed on the inner end wall of the bottom of the kiln body 1, and a temperature display 7 is also provided on the kiln body 1.

[0013] Preferably, the temperature display 7 is one of an LED digital tube, an LCD liquid crystal screen, and a quartz analog screen.

[0014] Principle of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com