Automatic discharging device

A blanking device and automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of heavy labor load and low efficiency of the operator, and achieve the effect of improving feeding efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

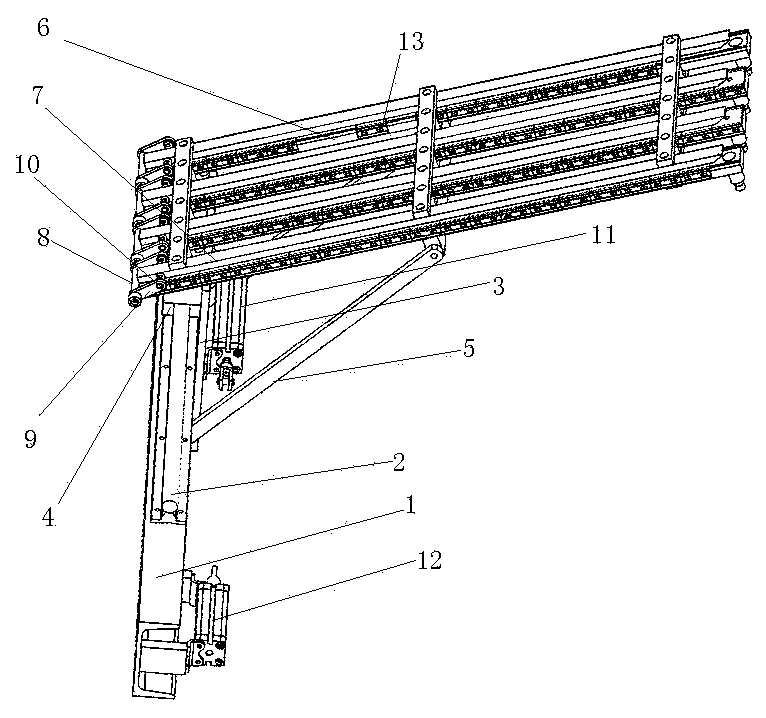

[0011] See figure 1 As shown, an automatic blanking device includes a base 1, a slide rail 2 is set on the base 1, a support plate 3 is slidably connected to the slide rail 2 through a slide seat 4, a support frame 5 is set on the support plate 3, and a support frame 5 is set on the support frame 5. A plurality of inclined linear guide rails 6, the upper end of each linear guide rail 6 is provided with a baffle plate 7 parallel to the linear guide rail 6, and a stopper 8 is provided at the outlet of the lower end of the linear guide rail 6; the stopper 8 is a cylindrical stopper, and the two ends of the stopper 8 Connect the connection plate 9, the connection plate 9 is connected to the baffle plate 7 through the rotating shaft 10; the inclination angle of the linear guide rail 6 is 30 degrees to 60 degrees, if it is too large or too large, the feeding speed is too fast or too slow, which affects the normal operation; on the support frame 5 Four linear guide rails 6 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com