Press for preventing test piece from moving in pressing and splicing process

A test piece and bonding technology, which is applied in the field of test piece pressure bonding machinery, can solve problems such as difficult sample quality and bonding failure, and achieve the effects of improving bonding quality and efficiency, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The press for preventing the test piece from moving during pressure bonding according to the present invention will be further described below through embodiments and in conjunction with the drawings.

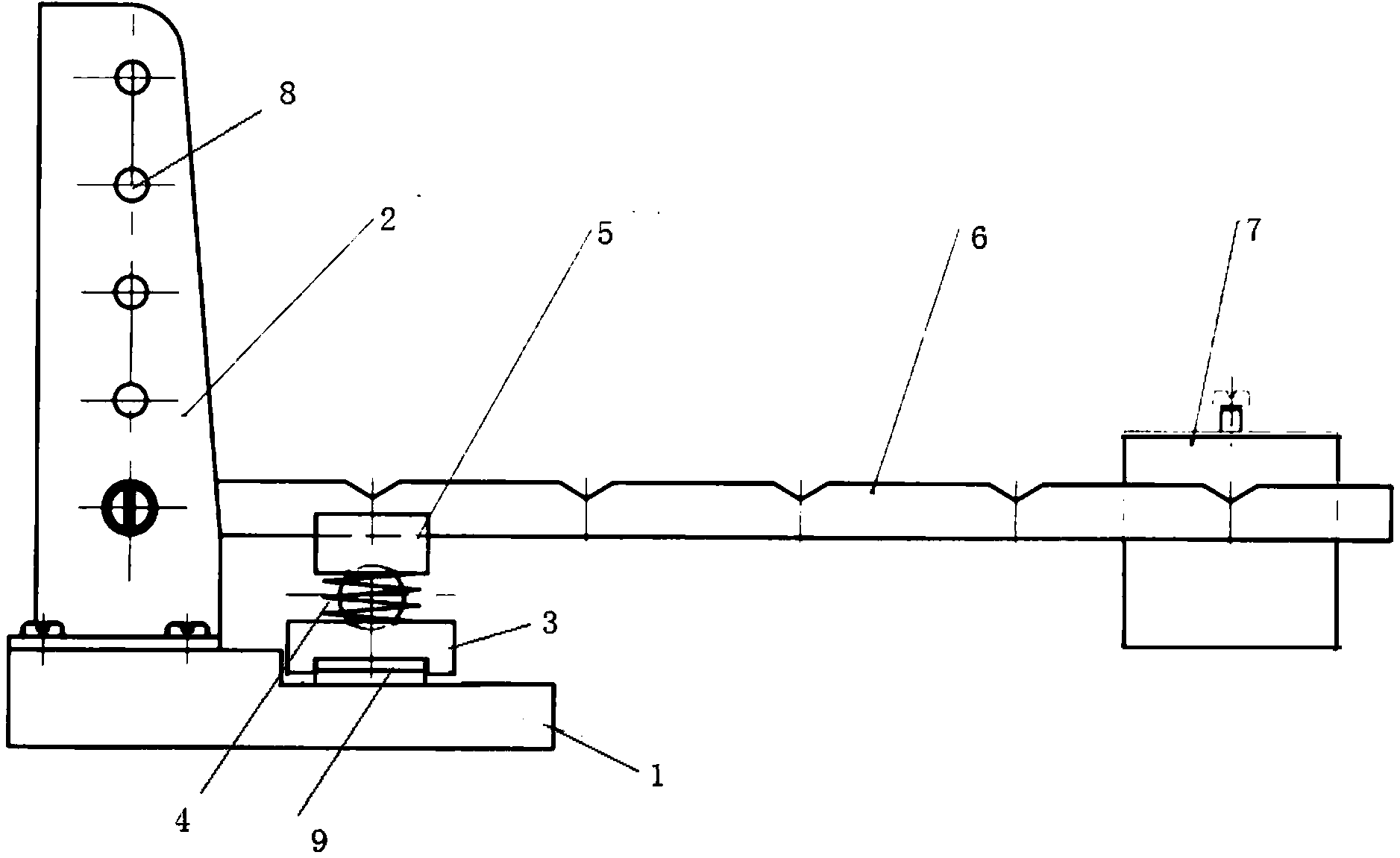

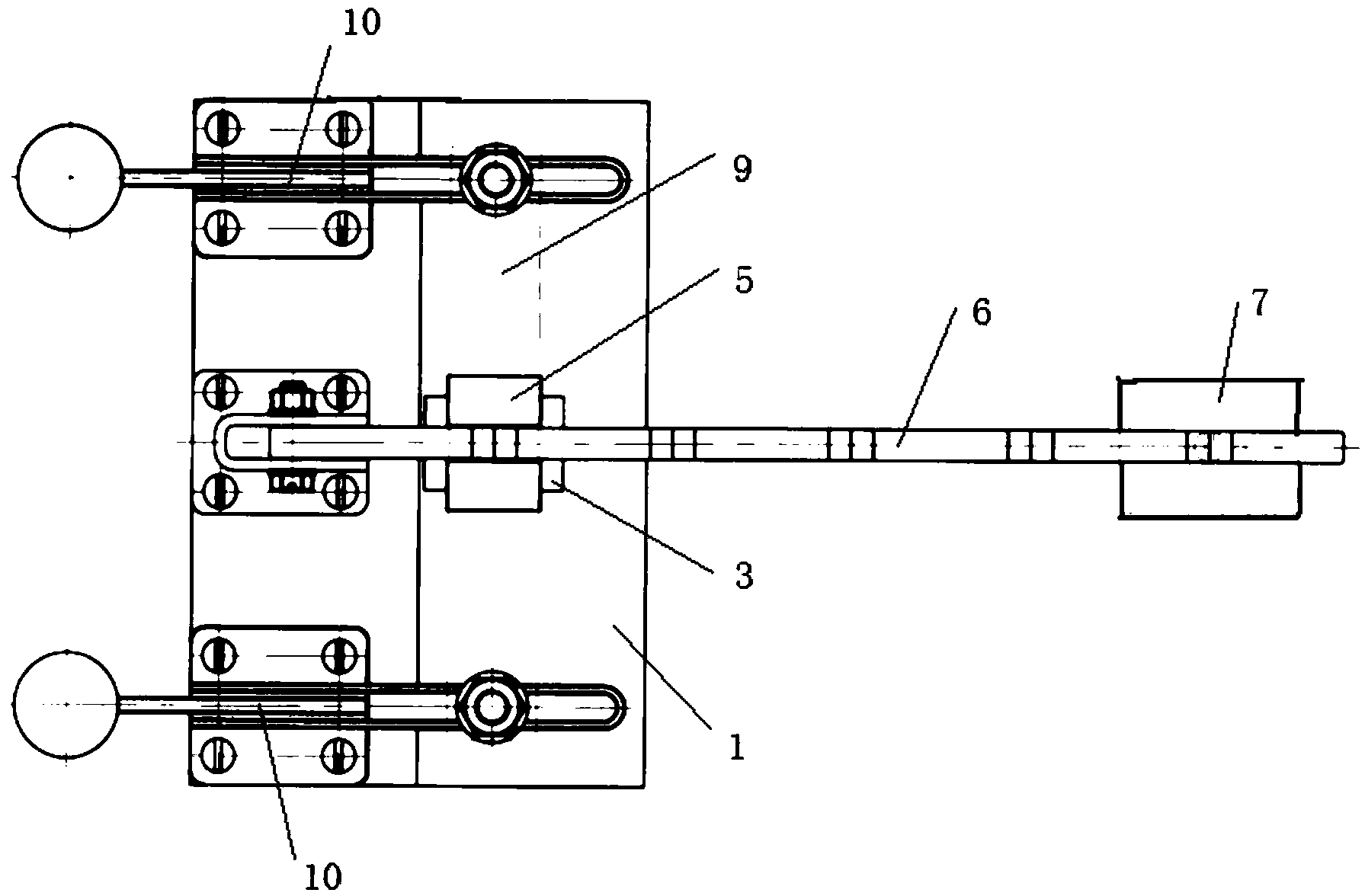

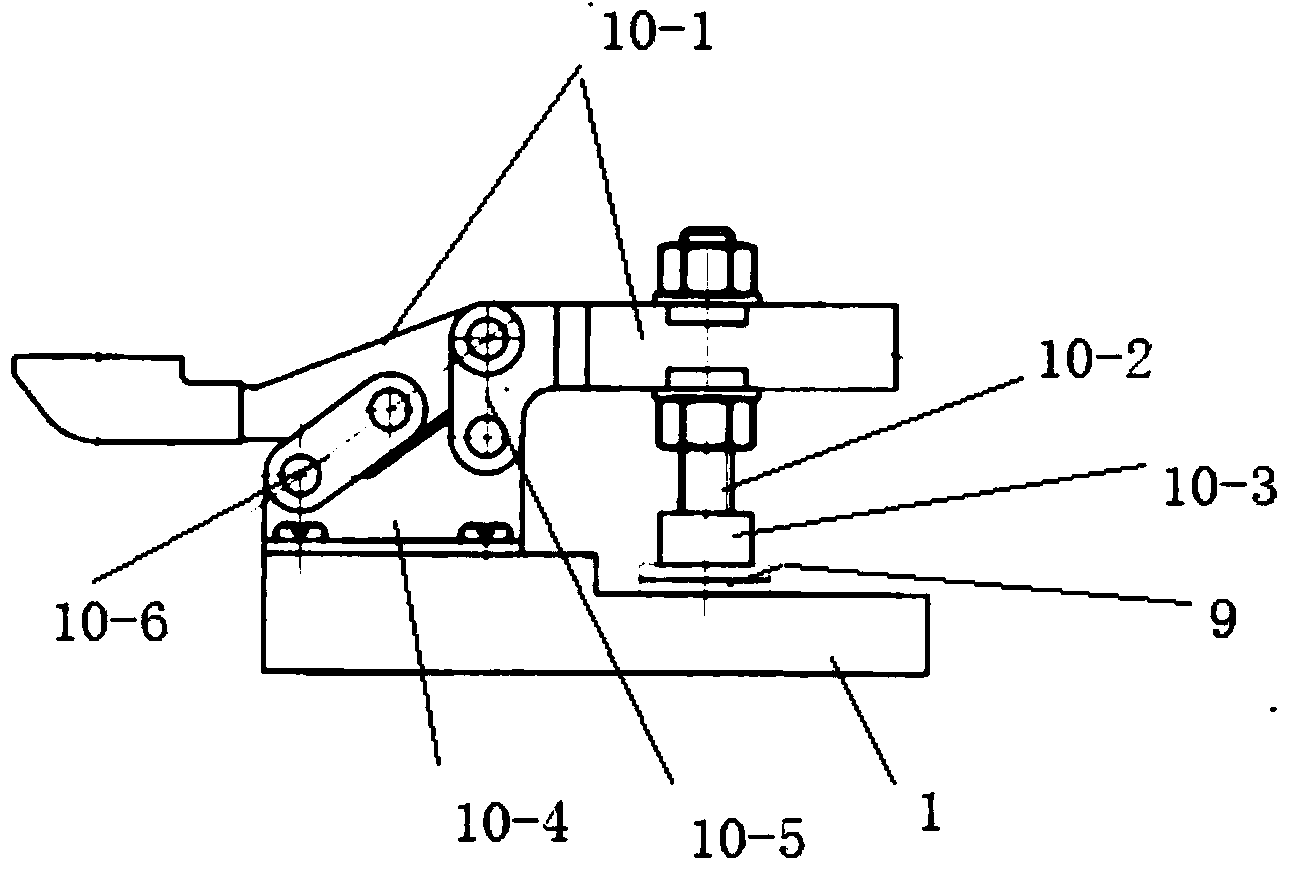

[0024] In this embodiment, the press that prevents the test piece from moving when pressure is applied is such as figure 1 , figure 2 As shown, it consists of a base 1, a main pressing device and two auxiliary pressing devices 10.

[0025] The base 1 is a stepped rectangular plate with a flat bottom surface and two different height surfaces. The higher top surface is used to install the main pressure device and two auxiliary pressure devices, and the lower top surface is used for Place the test piece.

[0026] The main pressure device consists of a support 2, a lever 6, a weight 7, a main pressure head 3, a spring 4 and a force transmission block 5. The support 2 is provided with five pairs of hinge shaft mounting holes 8 of different heights, and the spring 4 is Cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com