Box separator

A technology of separators and boxes, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of large workshop space, waste of manpower and material resources, and occupy a large amount of space, so as to save manpower and material resources, save workshop land, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

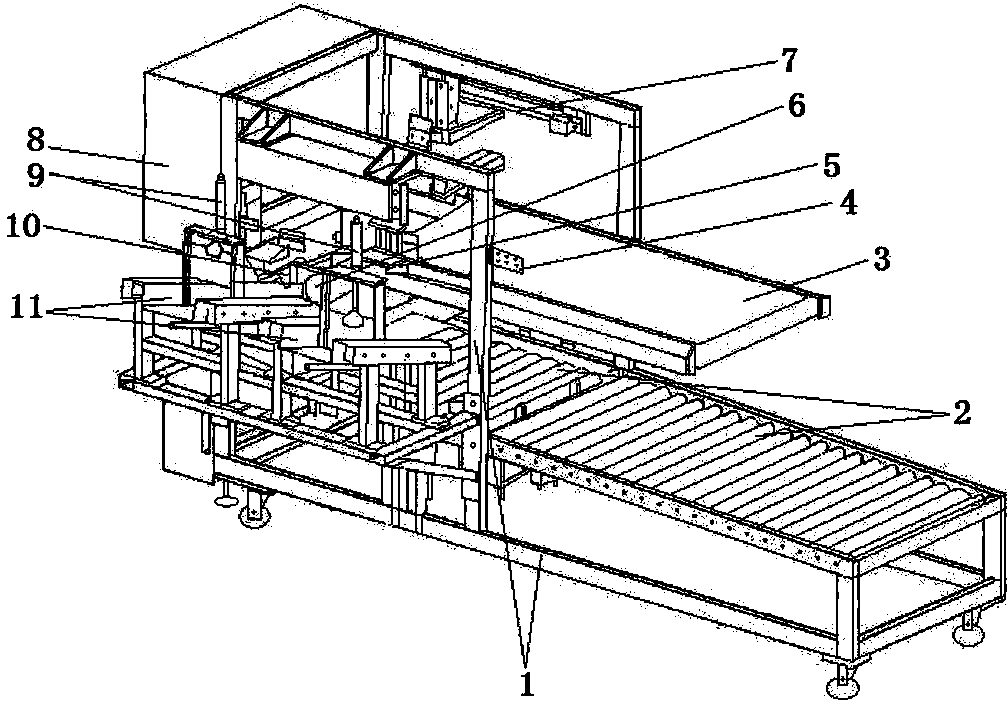

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] as attached figure 1 As shown, a box separator according to the present invention is characterized in that it includes a frame 1, a conveyor belt 3, a transmission device and a roller 2, and the top of the frame 1 is provided with a first cylinder 7 in a horizontal direction. The bottom of a cylinder 7 is provided with conveyor belt 3, and described conveyor belt 3 is installed in the middle of front and back both sides frame 1, and the front end of described conveyor belt 3 is connected with motor 6, and the outside vertical direction of described conveyor belt 3 is provided with There are two sets of conveying devices, the conveying devices are distributed between the left and right sides of the frame 1, their exit directions are consistent, and they share the same roller 2, and the conveying devices include an upper clamping device 5, a lower clamping device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com