top drive equipment

A technology for driving equipment and equipment, used in drilling equipment, drilling equipment and methods, impact drilling, etc. Small volume, reduced volume, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

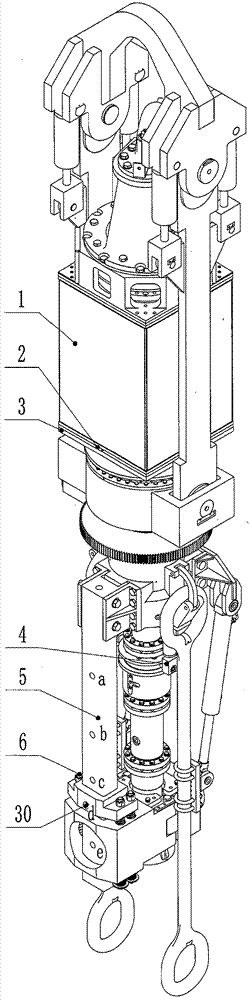

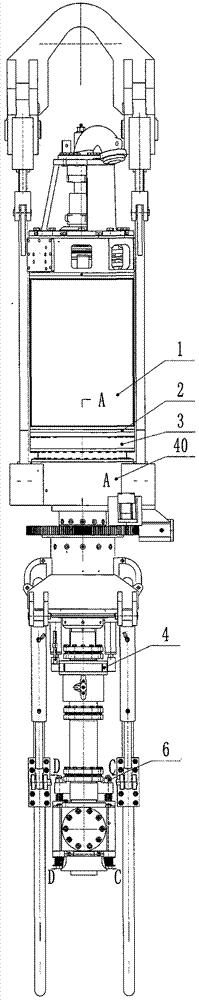

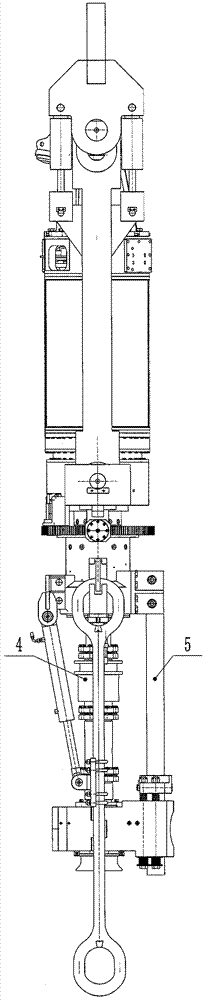

[0032] Such as figure 1 shown. The top drive includes an AC frequency conversion motor 1 for power transmission and a planetary reducer 3 with hollow (completely penetrated) input and output shafts; a center pipe 7; an automatic cock valve opening and closing device 4; a back clamp pipe processing device 6.

[0033] The AC frequency conversion motor 1 provides rotating power for the drilling tool of the well, Figure 4 The middle motor output shaft 8 is a hollow shaft completely penetrated in the middle, and the lower end of the motor output shaft 8 has EXT external splines.

[0034]The input shaft 9 of the planetary reducer 3, the input shaft 9 is a hollow shaft completely penetrated in the middle, the upper end of the input shaft 9 has an INT internal spline, and the lower end of the input shaft 9 has an externally meshed gear, and the externally meshed gear is used as a sun gear.

[0035] The EXT external spline at the lower end of the output shaft 8 of the AC variable fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com