Movable beam clamp for horizontal tensile testing machine

A technology of horizontal tensile test and moving beam, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low manual operation efficiency, affecting test efficiency, heavy bolt weight, etc., achieve simple structure, improve test efficiency, The effect of reducing physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

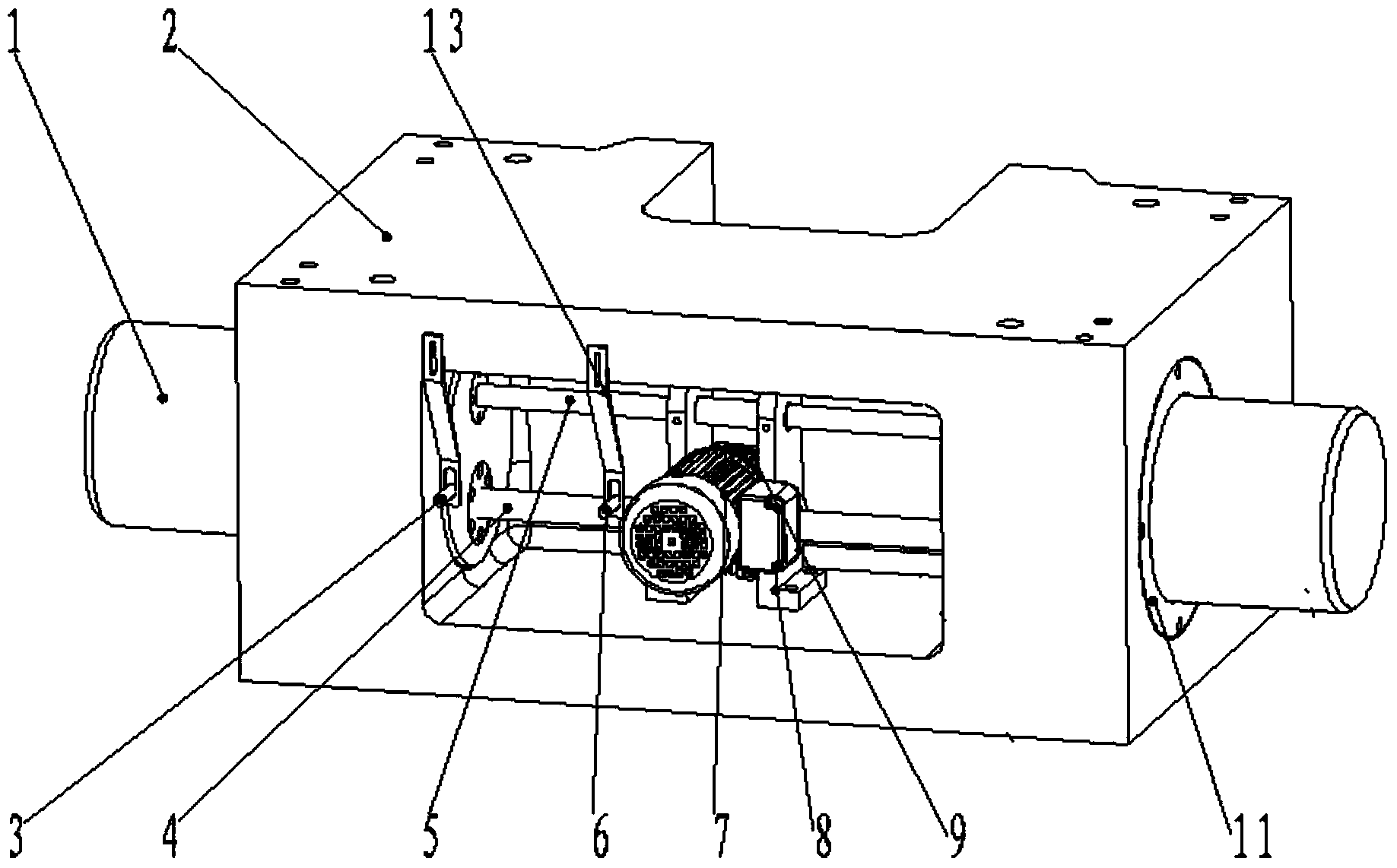

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The purpose of the present invention is to provide a horizontal tensile testing machine electric synchronous pin, the electric synchronous pin is suitable for fixing the moving beam of various horizontal tensile testing machine sample tests, the horizontal tensile testing machine electric synchronous pin does not need manual operation, The automation degree of the equipment is effectively improved, the labor intensity of the test personnel is reduced, and the test efficiency is improved.

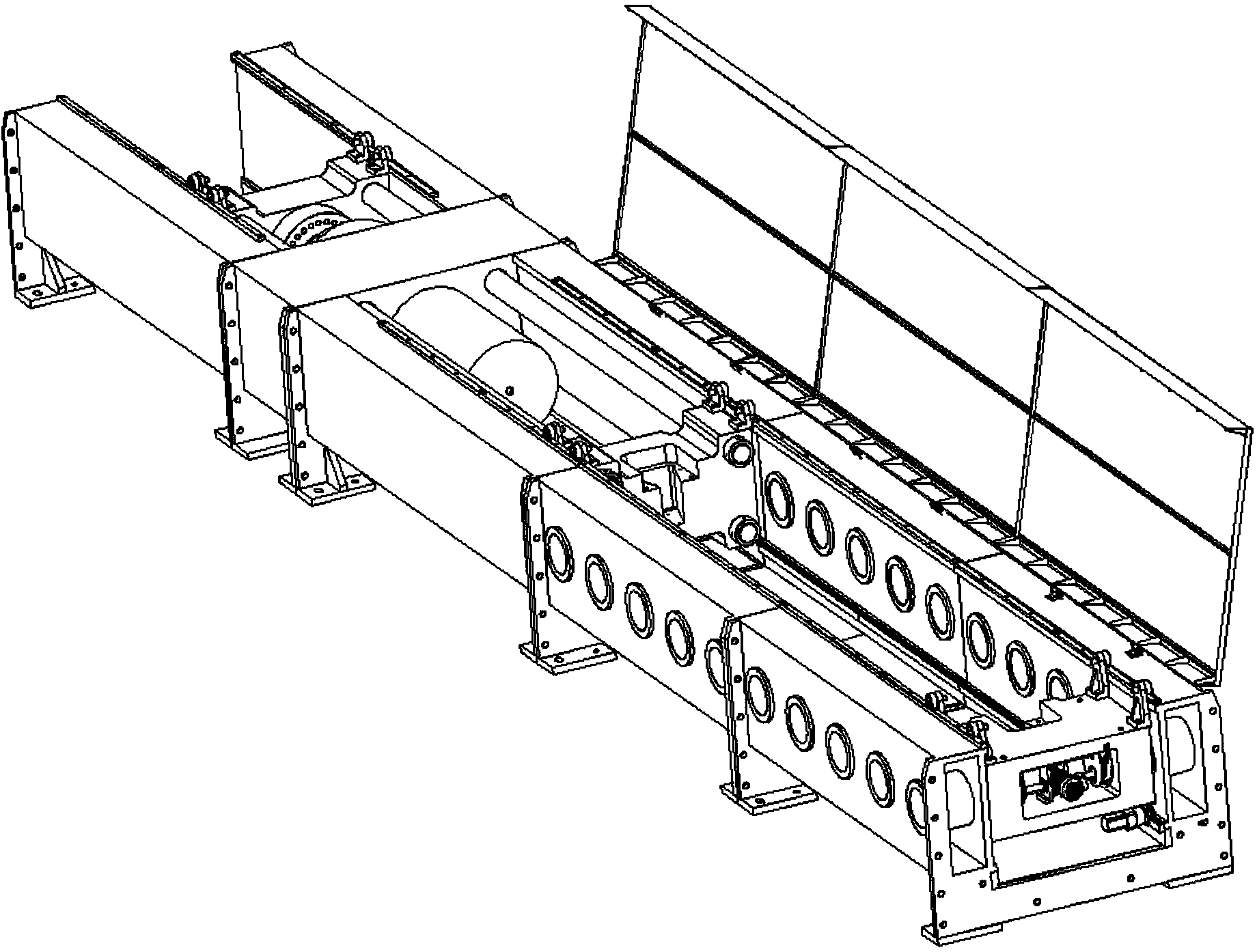

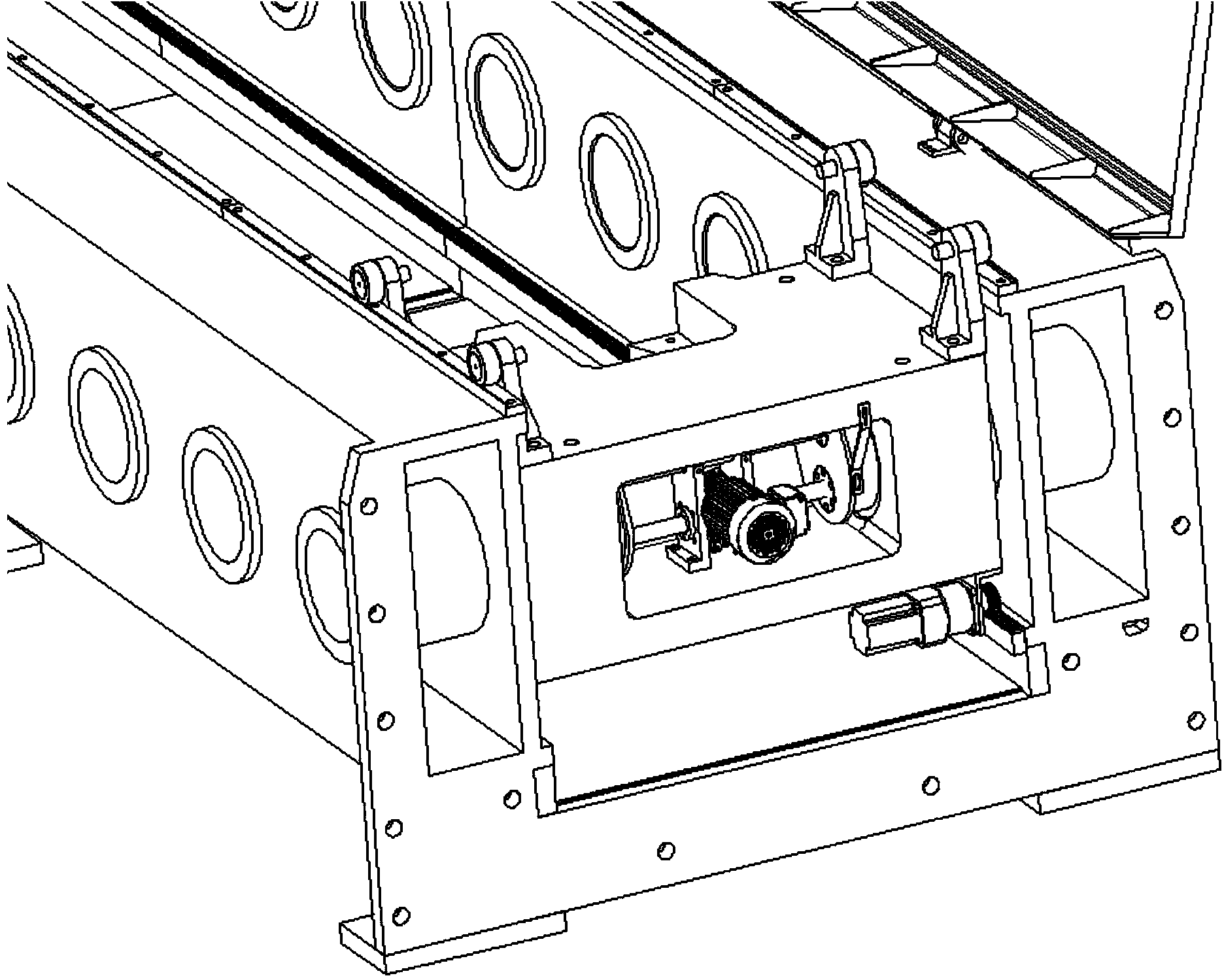

[0023] see figure 1 , 2 , the electric synchronous pin is actually integrated on the moving beam fixture. The moving beam fixture needs to be able to slide along the horizontal tensile testing machine. According to the length of the sample to be tested, select a suitable installation position and insert the pin into the horizontal tensile testing mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com