A modular multi-layer composite acoustic voltage metamaterial

A multi-layer composite and metamaterial technology, applied in electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., can solve the problem of weakening the acoustic-electric conversion of acoustic-electric transducers in holes Function and other issues, to achieve the effect of convenient independent processing and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

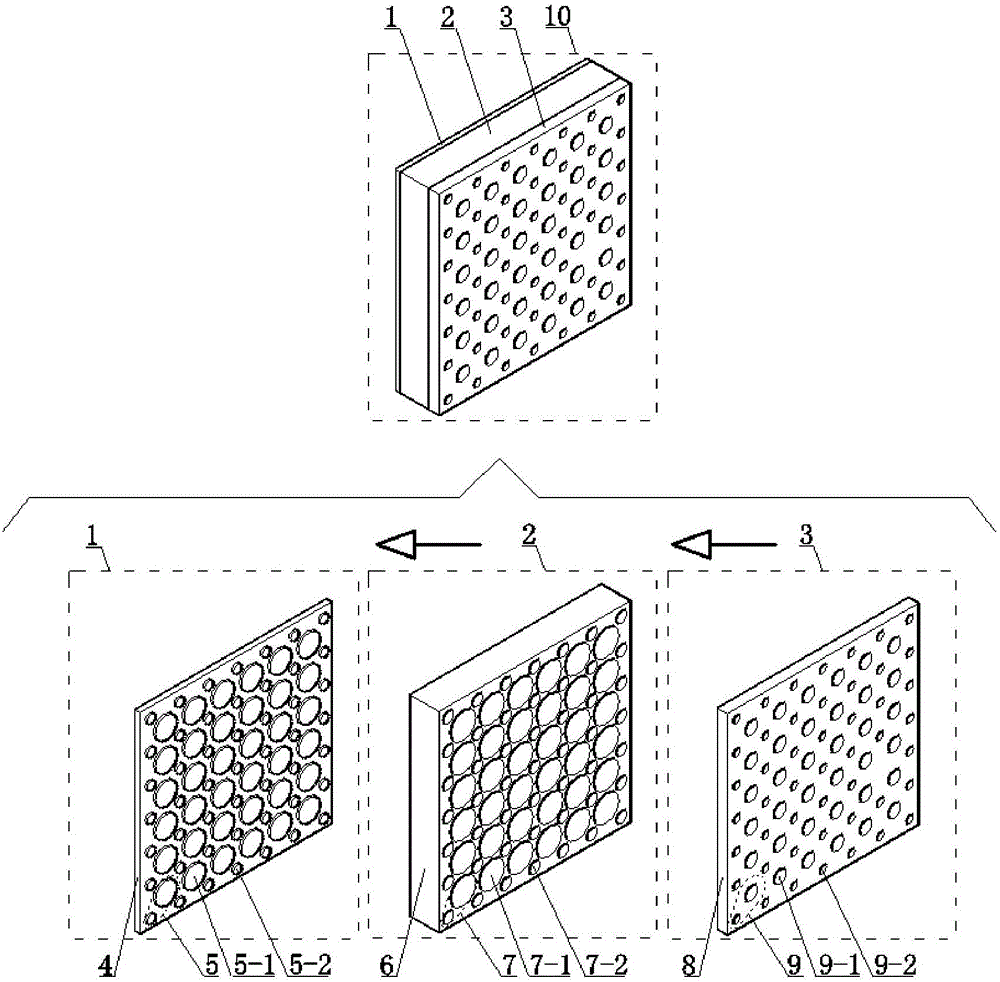

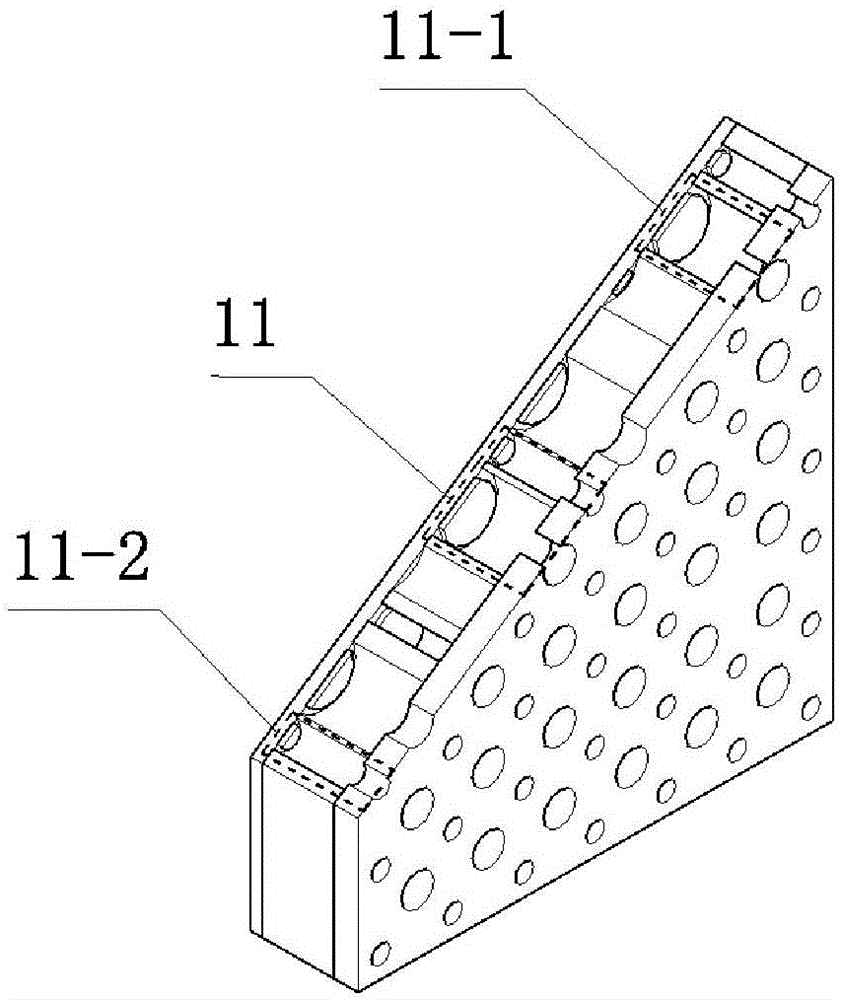

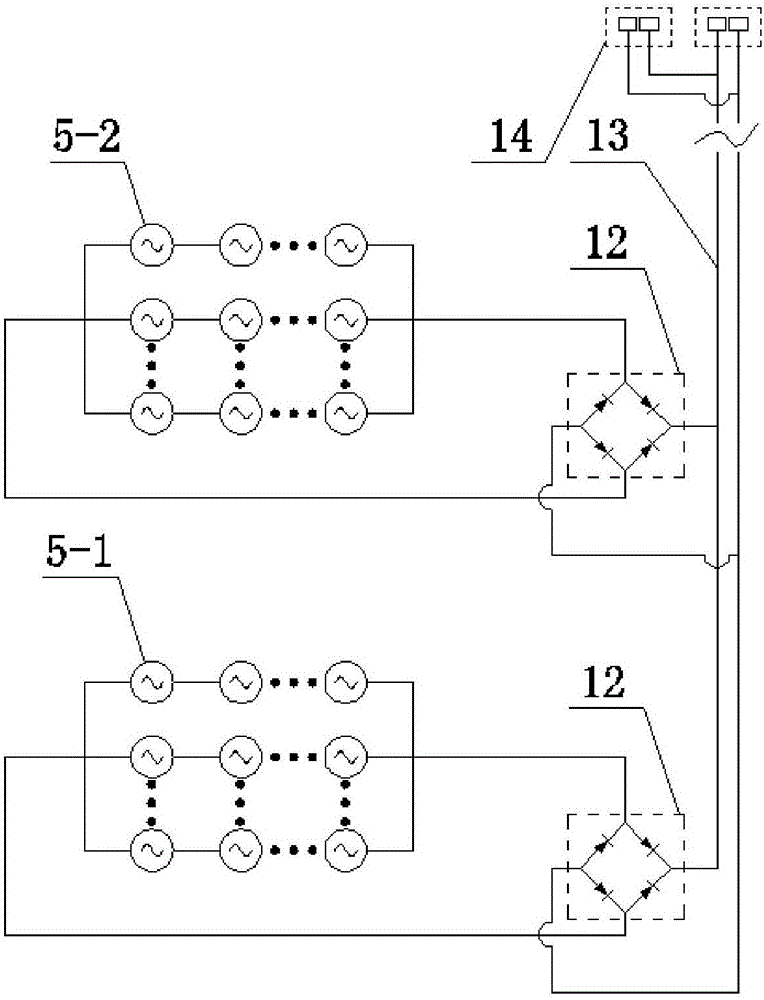

[0027] Such as figure 1 Shown is a modular multi-layer composite acoustic volt metamaterial, including a sheet-shaped acoustic volt module 10, which includes a sheet-shaped base layer 1, a cavity layer 2, and a neck layer 3 that are closely arranged in sequence. The base layer 1 includes an underlay substrate 4 and an acoustic-electric transducer 5 arranged on the underlay substrate 4, the cavity layer 2 includes a middle substrate 6 and a cavity 7 penetrating through the middle substrate 6, and the neck layer 3 includes the neck layer base material 8 and the neck hole 9 penetrating the neck layer base material 8; the positions of the acoustic-electric transducer 5, the cavity hole 7 and the neck hole 9 correspond one-to-one, and the corresponding group of acoustic-electric transducers The device 5, the cavity 7 and the neck hole 9 form an independent Helmholtz resona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com