Solid waste-based geopolymer mortar dry blend

A dry mixing and mortar technology, applied in cement production and other directions, can solve the problems of surrounding sea areas and land pollution, and achieve the effect of increasing added value, good practical application value and high toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

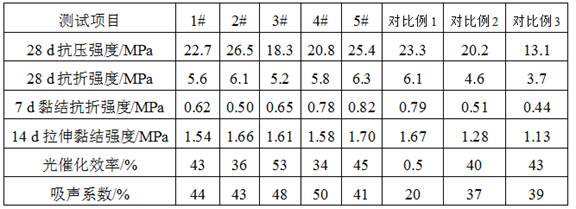

Examples

Embodiment 1

[0033] Example 1 Preparation of 1# solid waste base polymer mortar dry mix

[0034] Raw material ratio:

[0035] Pozzolanic cementitious material 10%, phosphorus slag powder 20%, sand 50%, vermiculite powder 7%, diatomite 6%, magnesium borate whisker 3%, modified nano titanium oxide 4%; the total amount of raw materials is 0.02% Polyvinyl alcohol and 4% base activator;

[0036] Preparation:

[0037] The first step is to prepare pozzolanic cementitious material

[0038] Mix kaolin, river silt and soda ash waste slag in a mixer at a weight ratio of 2:3:5 and put them into a high-temperature furnace. First, raise the temperature from room temperature at a rate of 10°C to 30°C / min. When the temperature reaches 600°C~700°C, change the heating rate to 25°C~50°C / min and continue to heat up to 750~950°C, keep warm for 0.5~2h and cool to room temperature; finally grind the calcined mixture to Particle size ≤75μm, sealed and stored for later use;

[0039] The second step is to prep...

Embodiment 2

[0045] Example 2 Preparation of 2# solid waste base polymer mortar dry mix

[0046] Raw material ratio:

[0047] 10% pozzolanic cementitious material, 15% phosphorus slag powder, 55% sand, 6% vermiculite powder, 7% diatomaceous earth, 4% magnesium borate whisker, 3% modified nano-titanium oxide; the total amount of raw materials is 0.03% Polyvinyl alcohol and 3% alkali activator;

[0048] Preparation method: with embodiment 1.

Embodiment 3

[0049] Example 3 Preparation of 3# solid waste base polymer mortar dry mix

[0050] Raw material ratio:

[0051] Pozzolanic cementitious material 20%, phosphorus slag powder 10%, sand 45%, vermiculite powder 5%, diatomite 10%, magnesium borate whisker 5%, modified nano-titanium oxide 5%; the total amount of raw materials is 0.03% Polyvinyl alcohol and 2% alkali activator;

[0052] Preparation method: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com