Piston for an internal combustion engine

A technology for internal combustion engines and pistons, applied to pistons, mechanical equipment, engine components, etc., can solve problems such as insufficient cooling, and achieve the effect of ensuring axial positioning in a simple way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

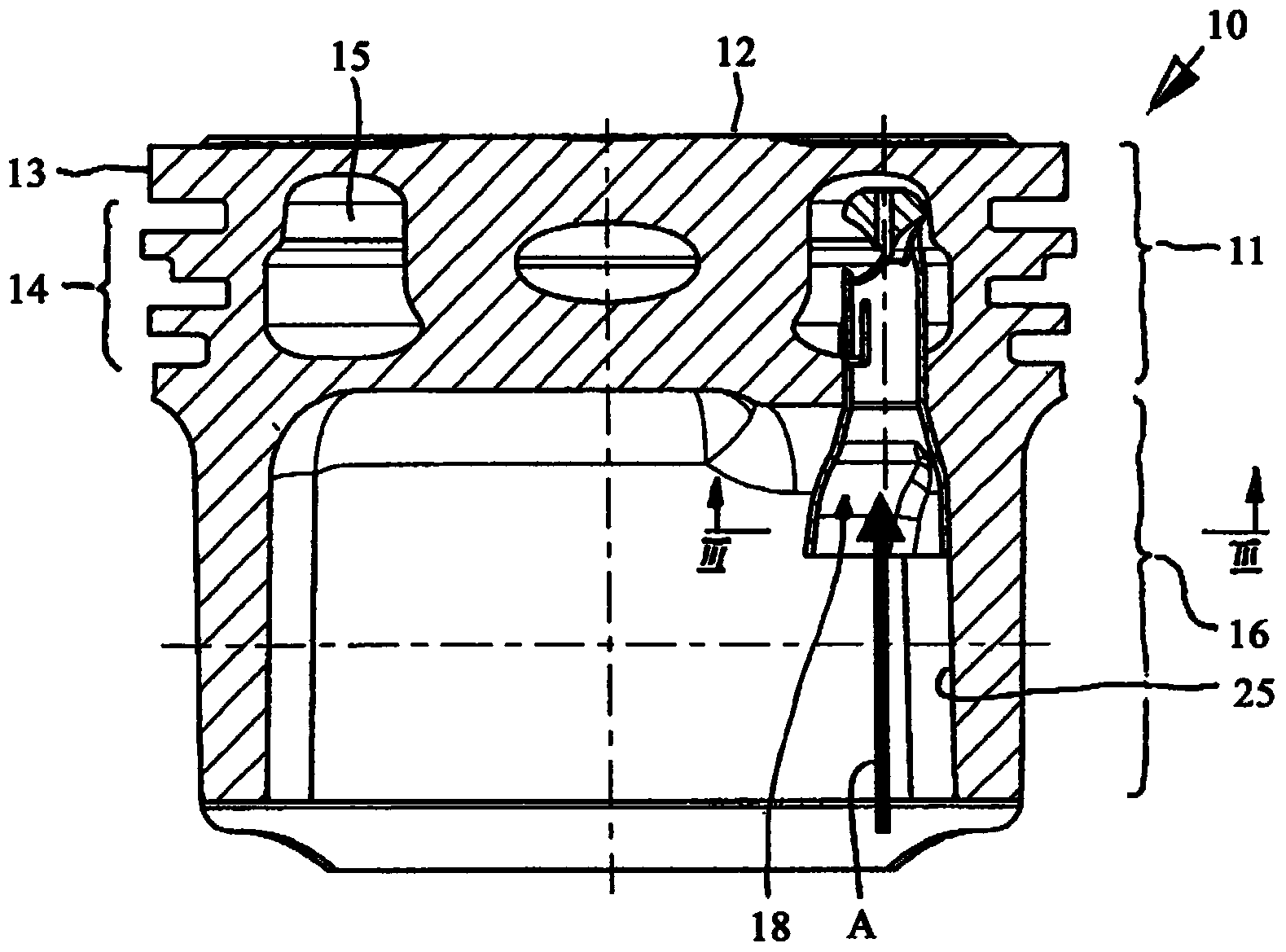

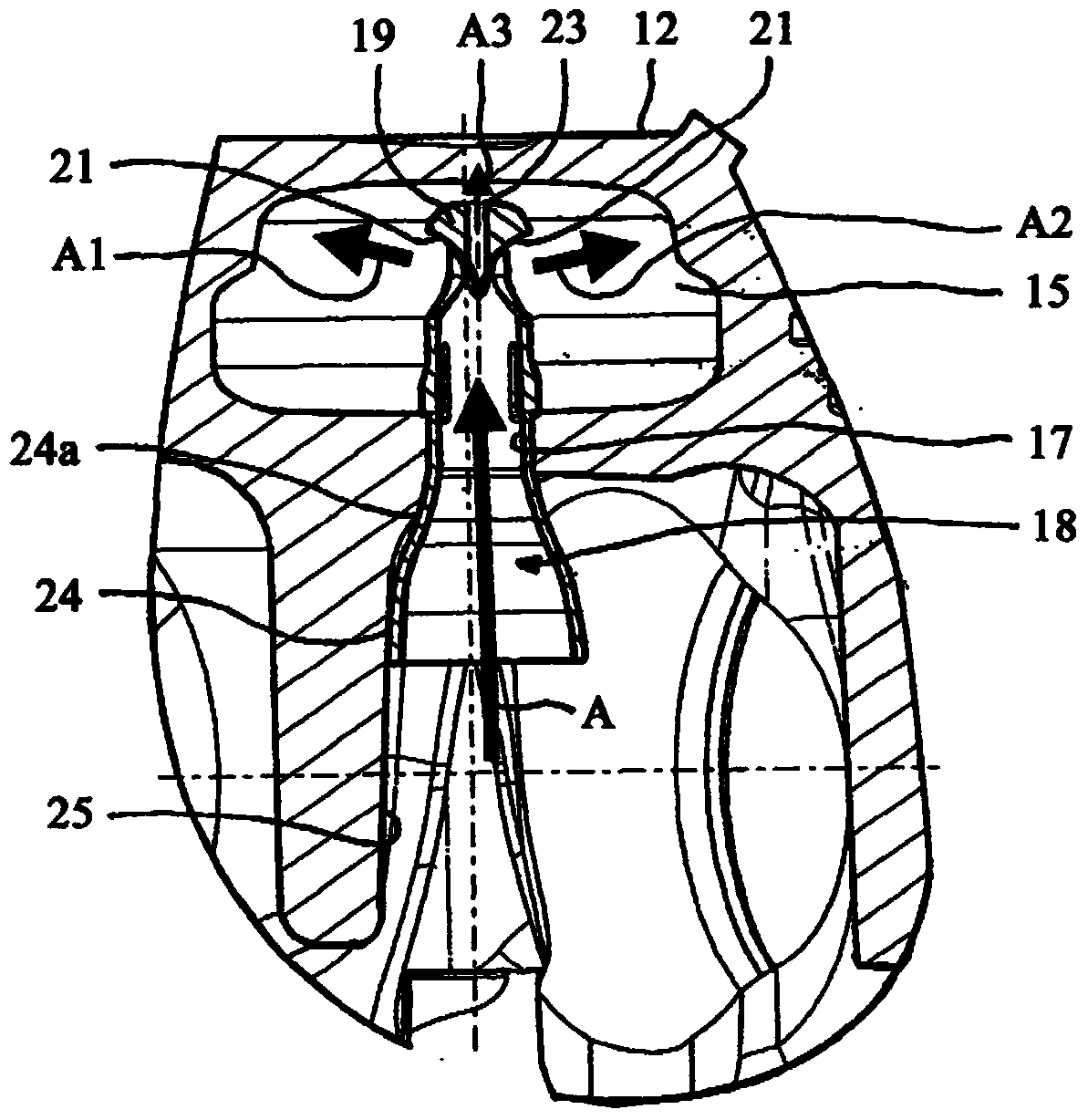

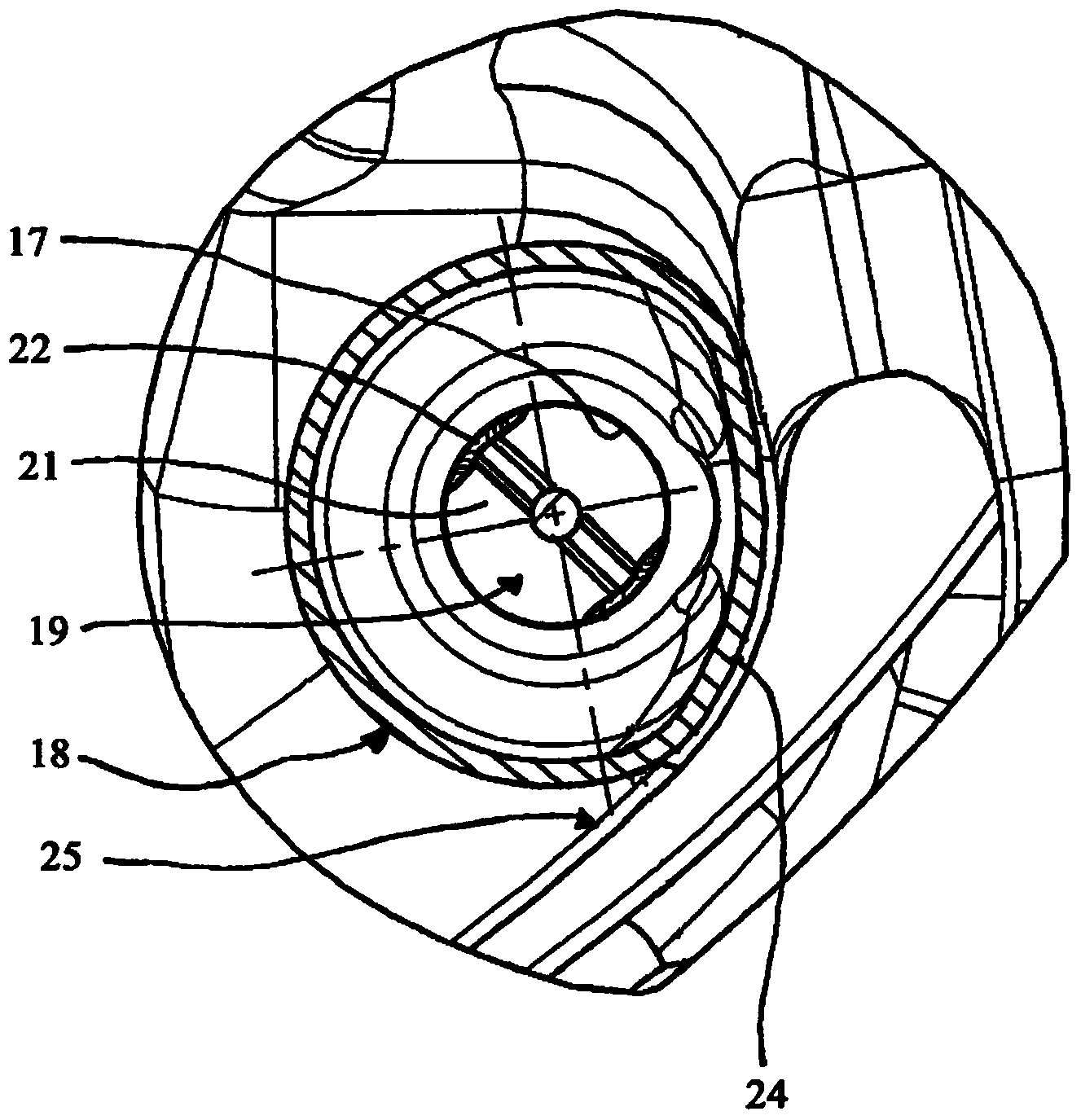

[0020] exist Figures 1 to 3 A piston 10 according to the invention for an internal combustion engine is shown by way of example. The one-piece piston 10 in the exemplary embodiment has a piston head 11 with a piston crown 12 which can be provided in a known manner with a piston crown pocket (not shown in the figures). An annular fire land 13 and an annular piston ring band 14 having an annular groove are connected to the piston top 12 , and the annular groove is used to accommodate a piston ring (not shown in the figure). An annular cooling channel 15 is provided in the region of the piston ring band 14 . In addition, the piston 10 also has a piston skirt 16 in a known manner.

[0021] The piston 10 operates in a block crankcase, which is provided in a known manner with nozzles, by means of which the cooling oil fluid A is injected into a bore hole 17 , which in the exemplary embodiment is of substantially cylindrical design . The bore 17 opens into the cooling channel 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com