Method of wind turbine yaw angle control and wind turbine

A wind turbine, yaw angle technology, applied in wind turbine yaw angle control, wind turbine field, can solve problems such as long-term operation, regular inspection of resistance strain gauges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

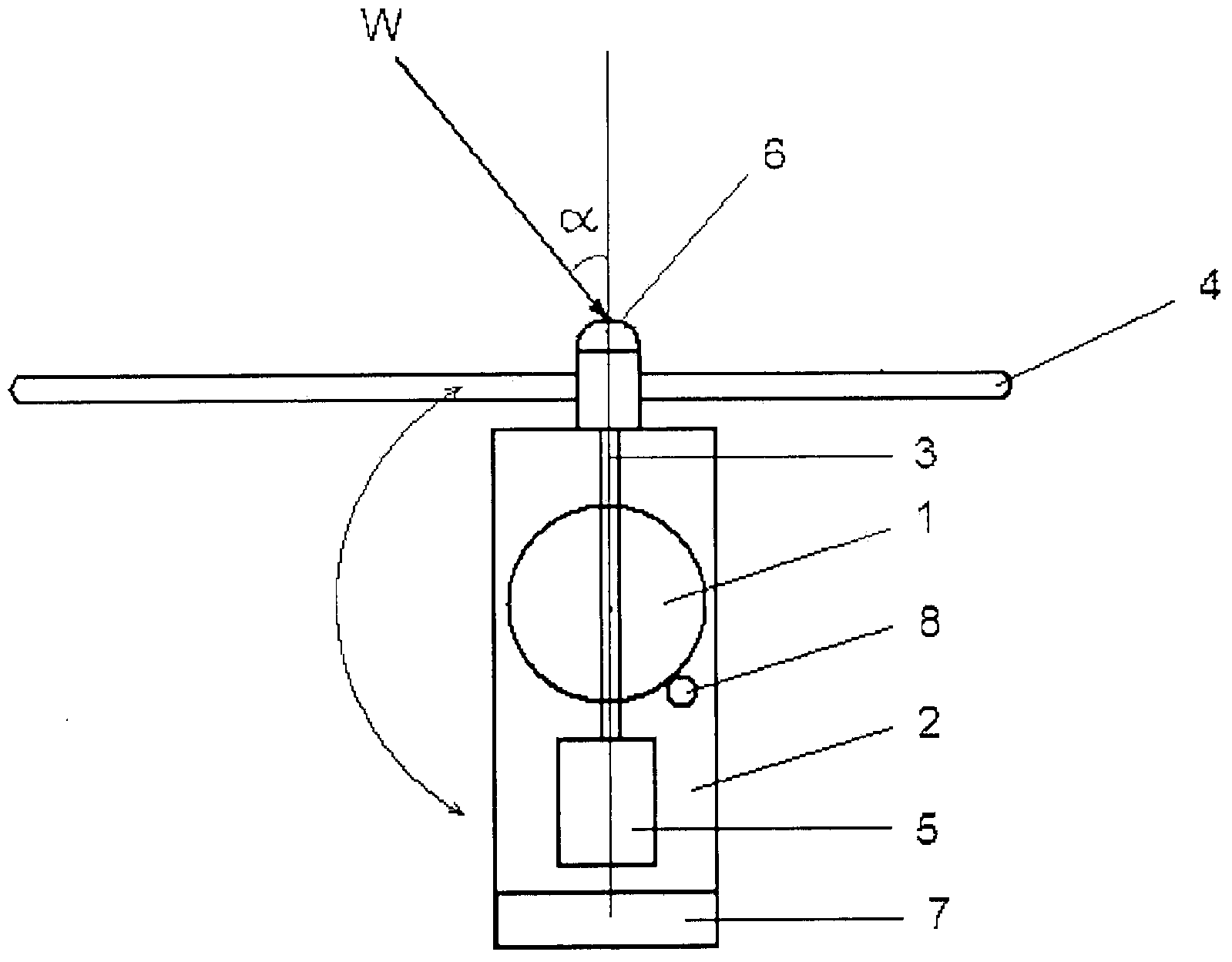

[0037] figure 1 A wind turbine according to the invention for implementing the method according to the invention is schematically shown, the wind turbine comprising a tower 1 on which is mounted a nacelle 2 rotatable about a vertical axis, and a rotor shaft 3, in the present In said embodiment of the invention, the rotor is rotatable about a horizontal axis and is formed and mounted in the nacelle 2 by three blades for converting wind energy into rotational motion of the rotor shaft. Typically, the rotor shaft axis is offset from the wind direction W by an angle α. A generator 5 is mechanically connected to the rotor shaft 3 . To control the yaw angle of the rotor, the wind turbine is equipped with a blade position sensor 6, a yaw controller 7, and a nacelle yaw drive 2 (yaw actuator 8) integrated in a closed-loop automatic control.

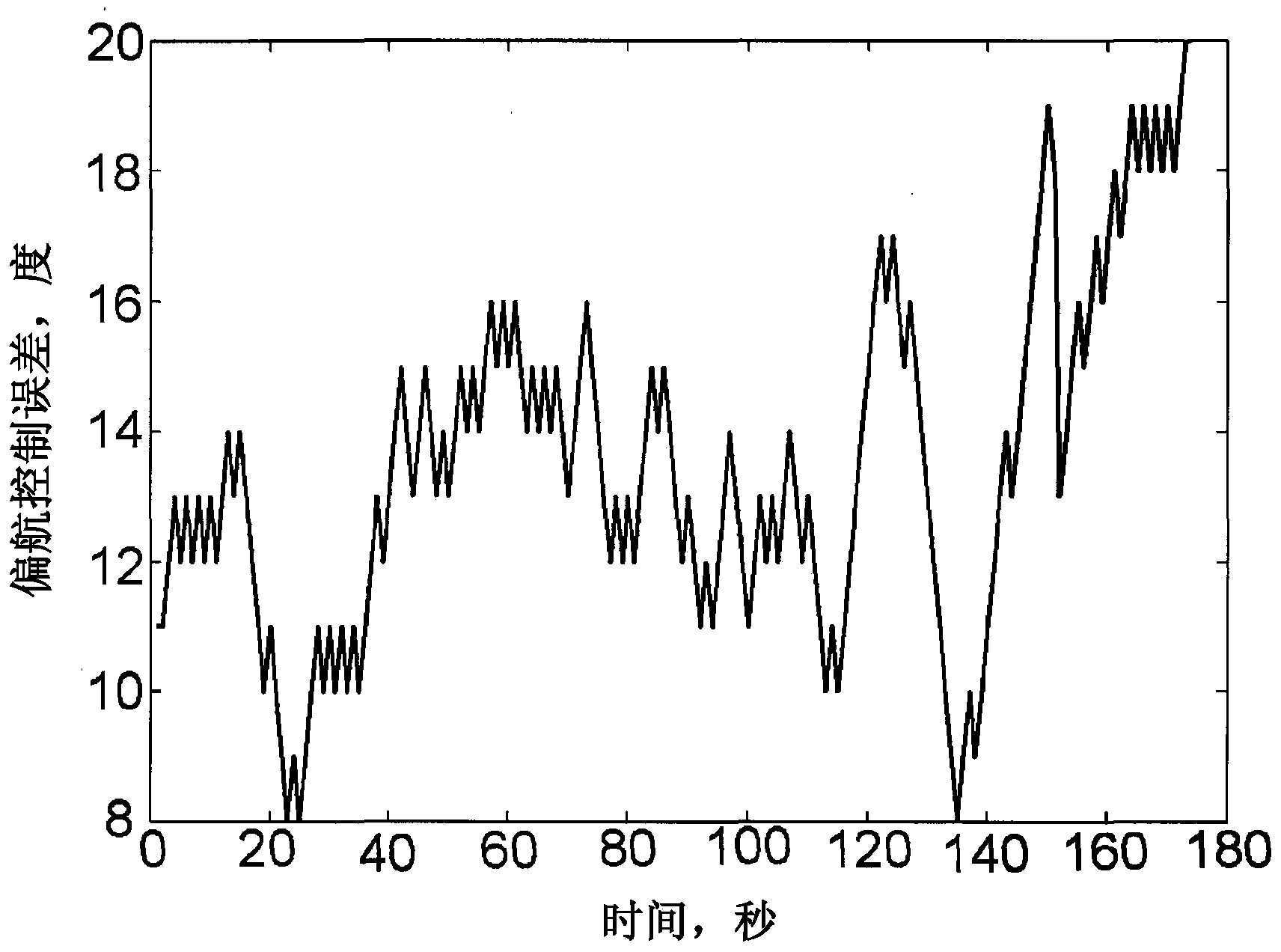

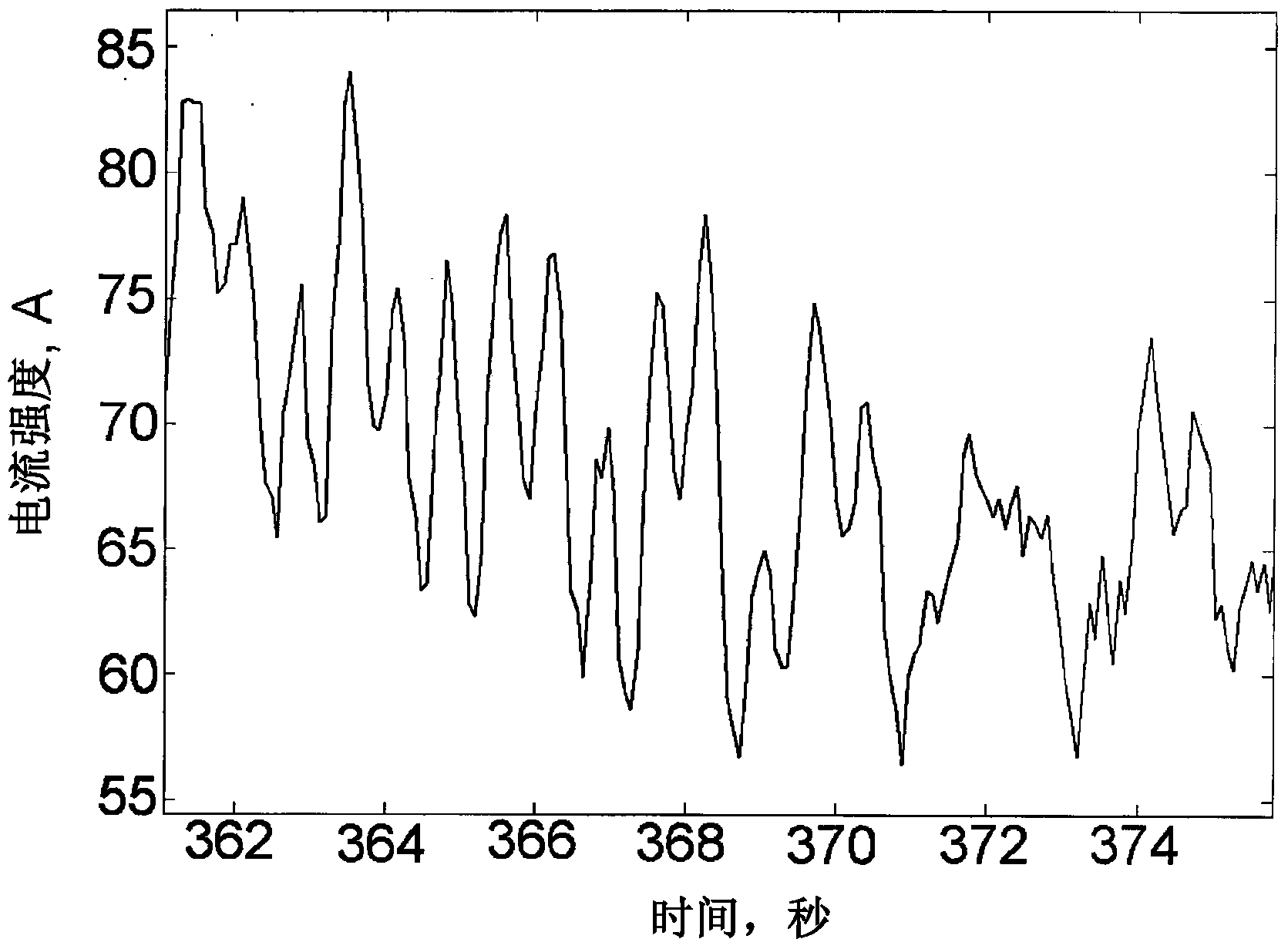

[0038] The WT rotor yaw control method is based on the non-contact measurement of the current parameters of the wind turbine induction genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com