Sealing device and damper with sealing device

A sealing device and dust-proof sealing technology, which is applied to the sealing of engines, shock absorbers, shock absorbers, etc., and can solve problems such as working fluid leakage, user discomfort, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. The same reference numerals used in some of the figures denote the same or corresponding parts.

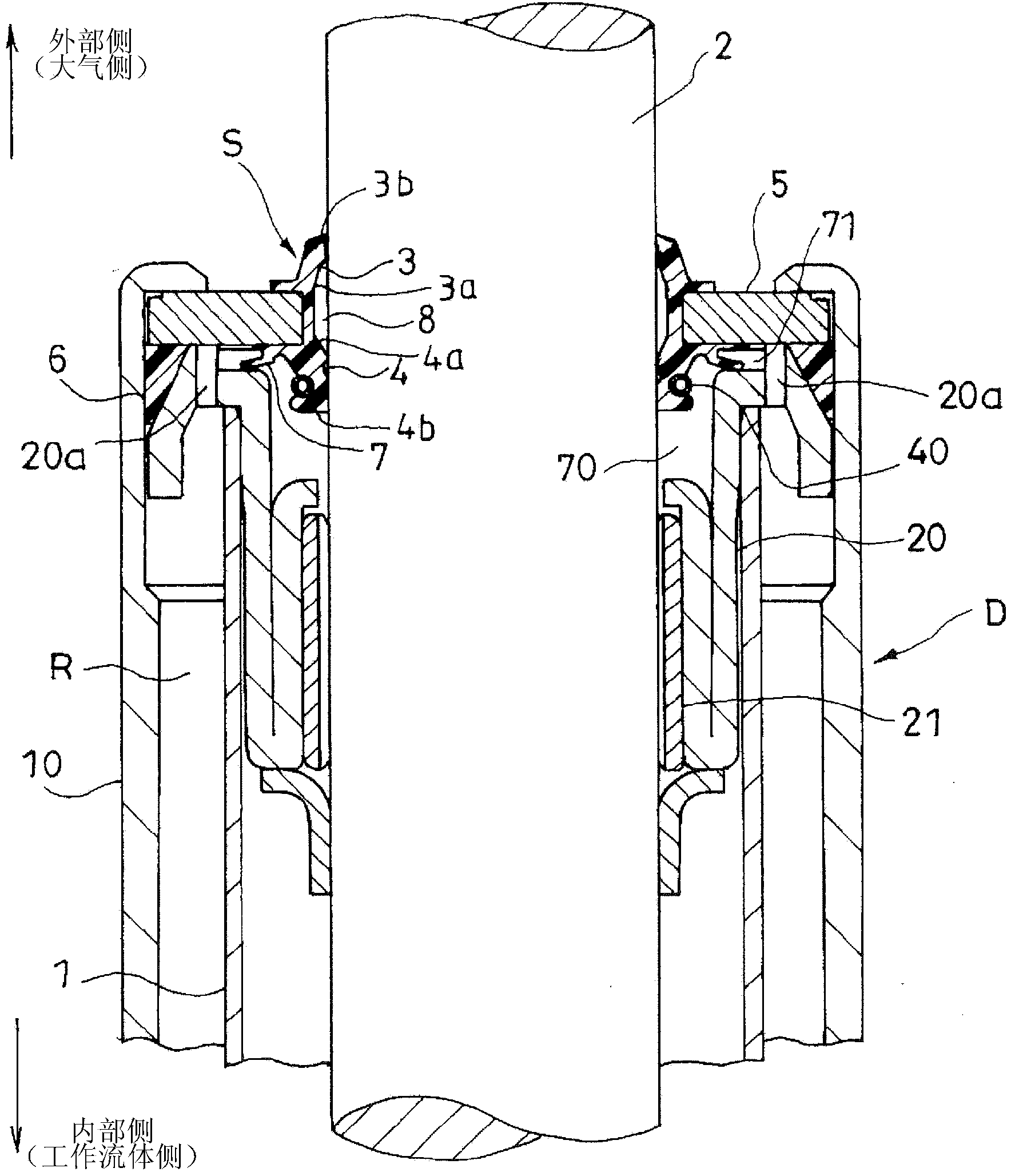

[0028] like figure 1 As shown, a sealing device S is used to seal the outer periphery of a piston rod (shaft member) 2 movably inserted into a cylinder (cylinder member) 1 for accommodating a working fluid. The sealing device S includes: a dust seal flange 3 arranged on the outer side (atmosphere side) of the cylinder block 1 to prevent the intrusion of foreign matter; and an oil seal flange 4 arranged on the inner side (working fluid side) of the cylinder block 1 side) and is used to prevent the outflow of working fluid. A space in which the working fluid resides is formed between the dust seal flange 3 and the oil seal flange 4 .

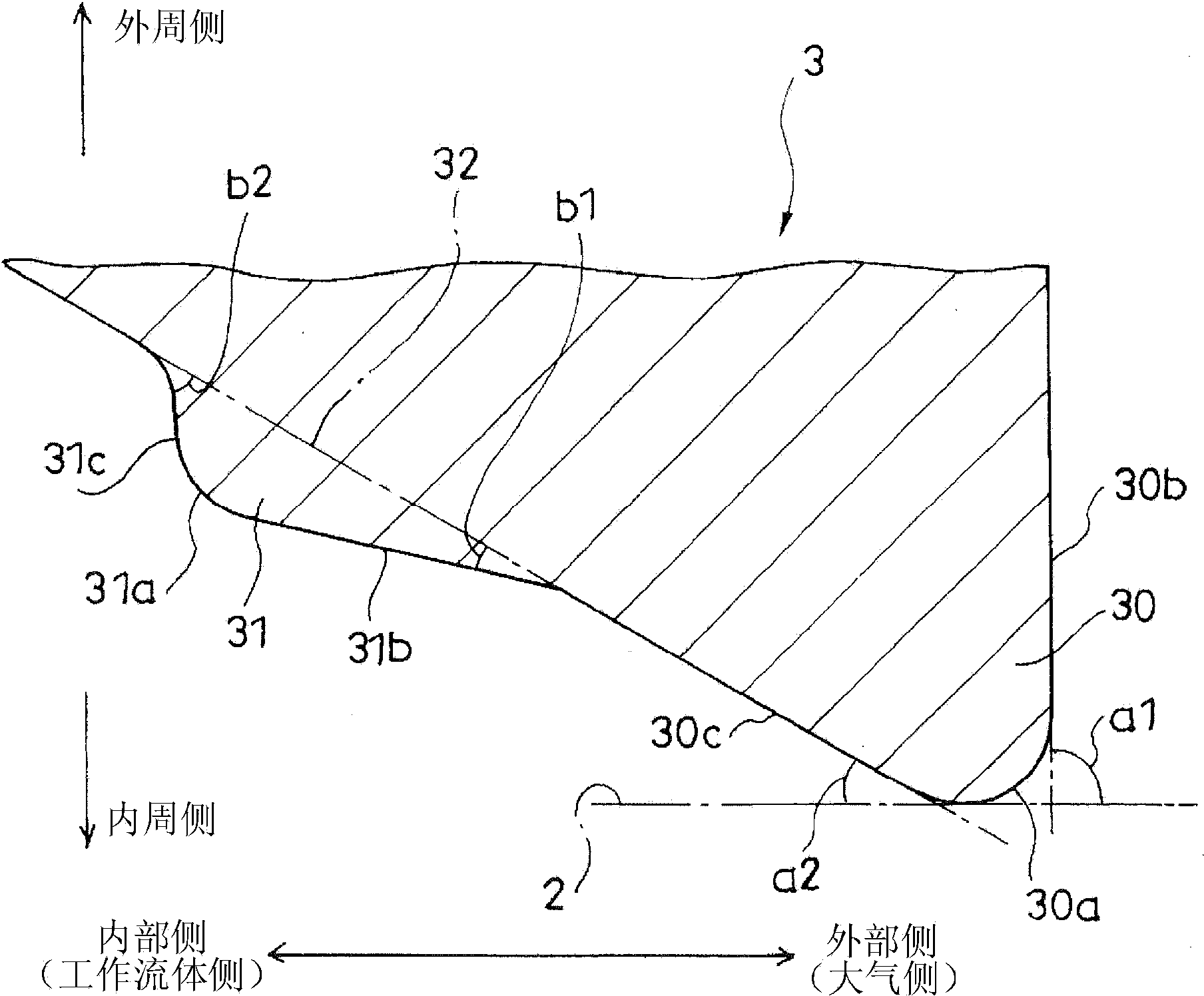

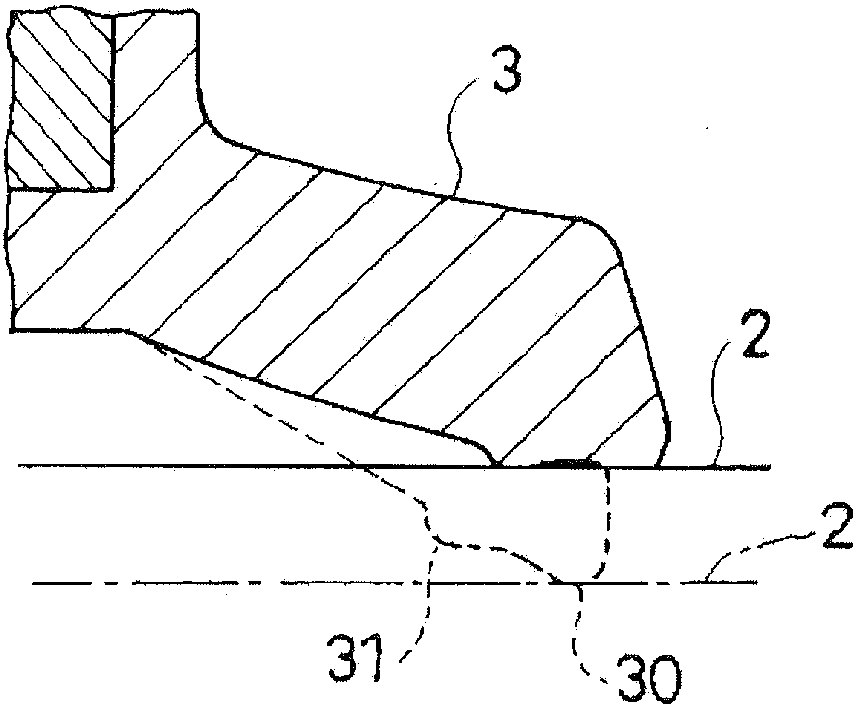

[0029] like figure 2 As shown, the dust seal flange 3 includes a main flange portion 30 and a sub flange portion 31 formed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com