Food forming device

A technology for food forming and ingredients, which is applied in the fields of food forming, food preparation, food science, etc., can solve the problems of uneven distribution of sushi rice and inability to carry out rolling operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

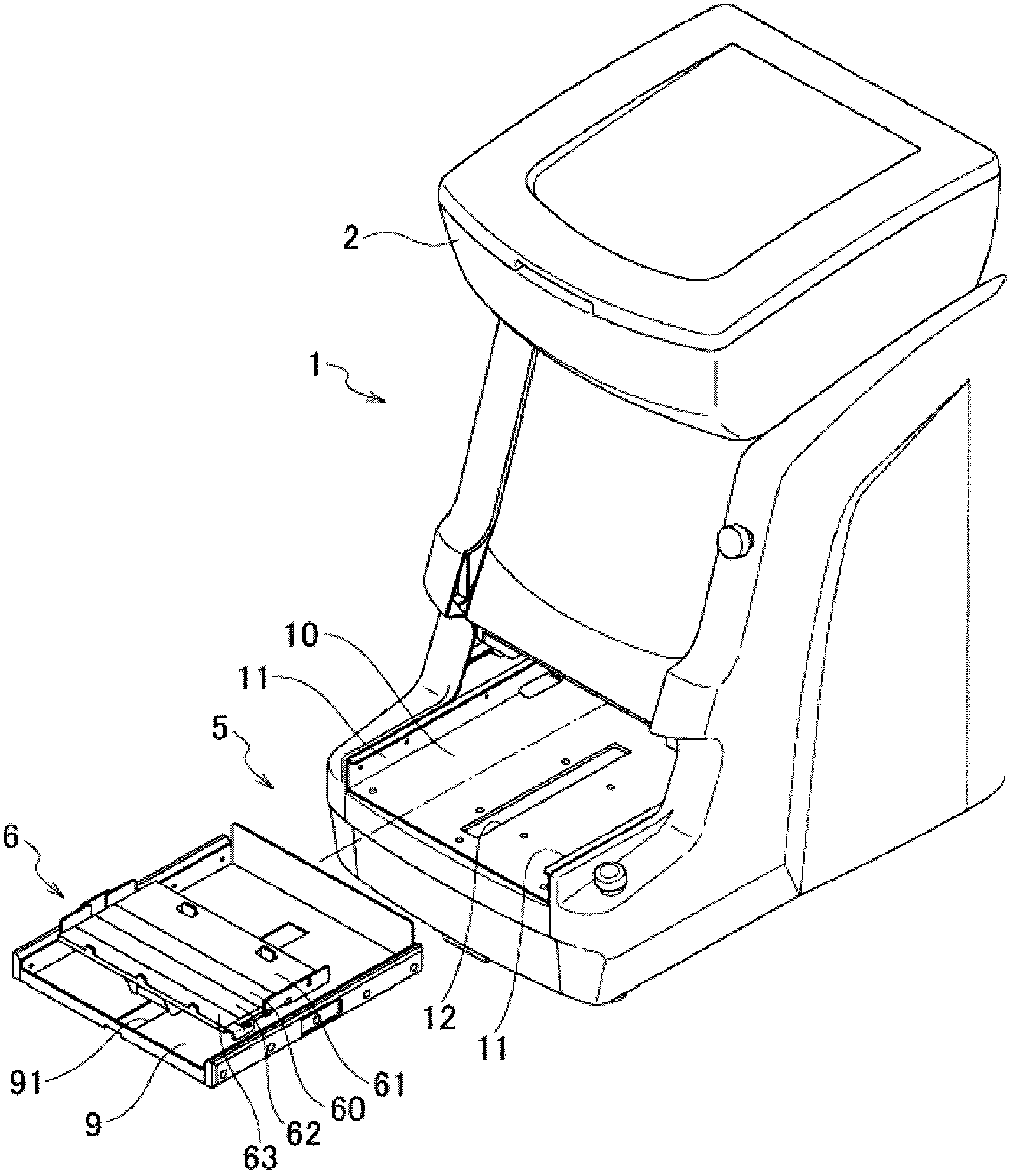

[0043] (overall overview)

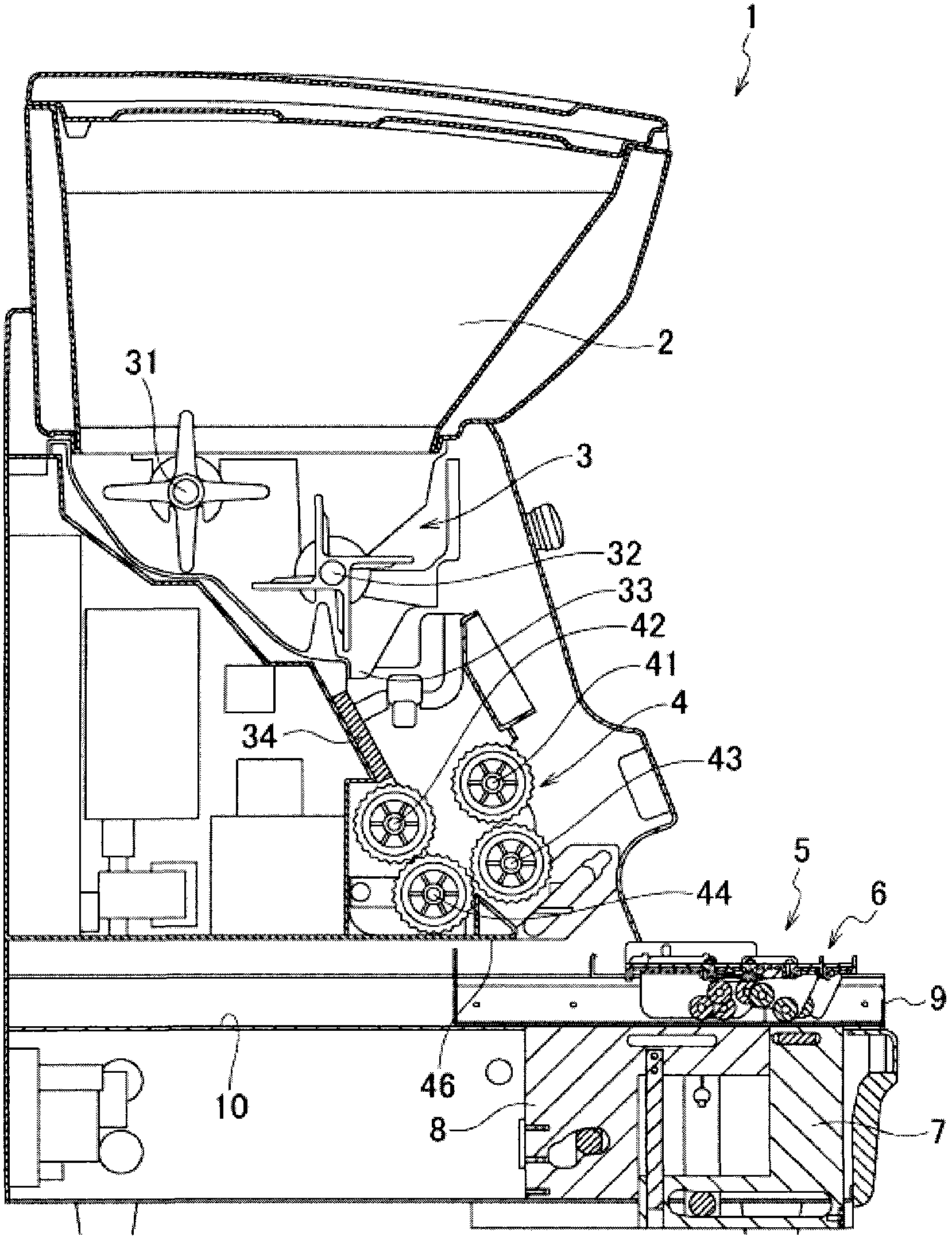

[0044] exist figure 1 , figure 2 Among them, as its main components, the food forming device 1 has: a hopper 2, which accommodates sushi rice as a material; a stirring unit 3 for the sushi rice; a rolling unit 4, which rolls the stirred sushi rice into a plate shape; And a forming unit 5, which forms the rolled sushi rice into a stick shape. The stirring unit 3 includes first and second stirring blades 31 and 32 below the hopper 2 , and both stir the sushi rice in the hopper 2 . The 2nd stirring fan blade 32 is positioned at the slanting lower part of the 1st agitating fan blade 31, and it further stirs the sushi rice that has been stirred by the 1st agitating fan blade 31 and falls obliquely downward due to gravity, and then flows from the outlet 33 to the calendering unit. 4 export.

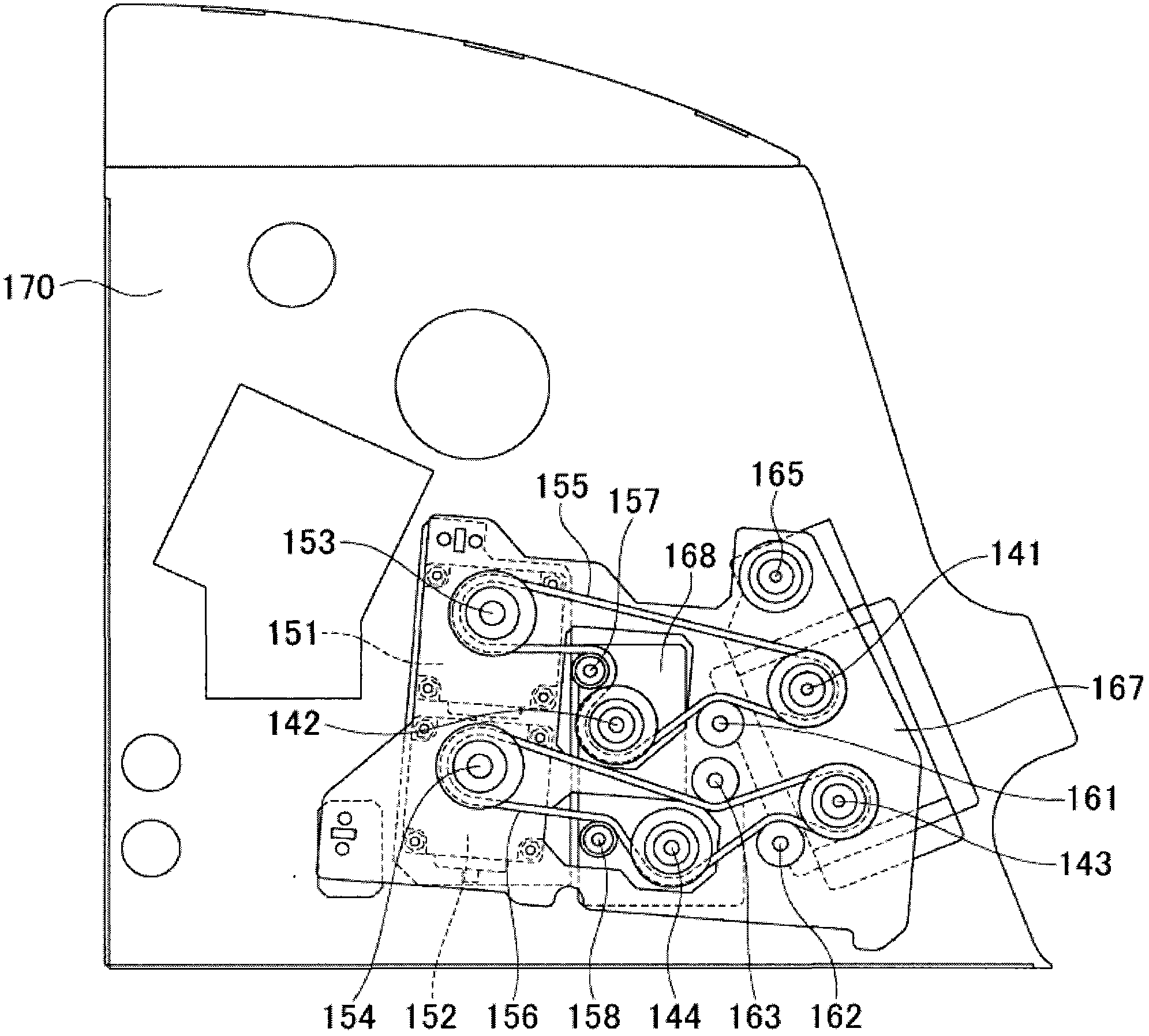

[0045] The sushi rice exported from the outlet 33 is guided to the rolling unit 4 by the inclined guide 34 . The rolling unit 4 has four rollers, namely: the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com