Vegetable washing machine with self-cleaning function

A vegetable washing machine and self-cleaning technology, applied in the field of daily sanitation, can solve problems such as complex mechanical structure, high labor intensity, and dirt retention, and achieve high cleaning efficiency, good cleaning effect, and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

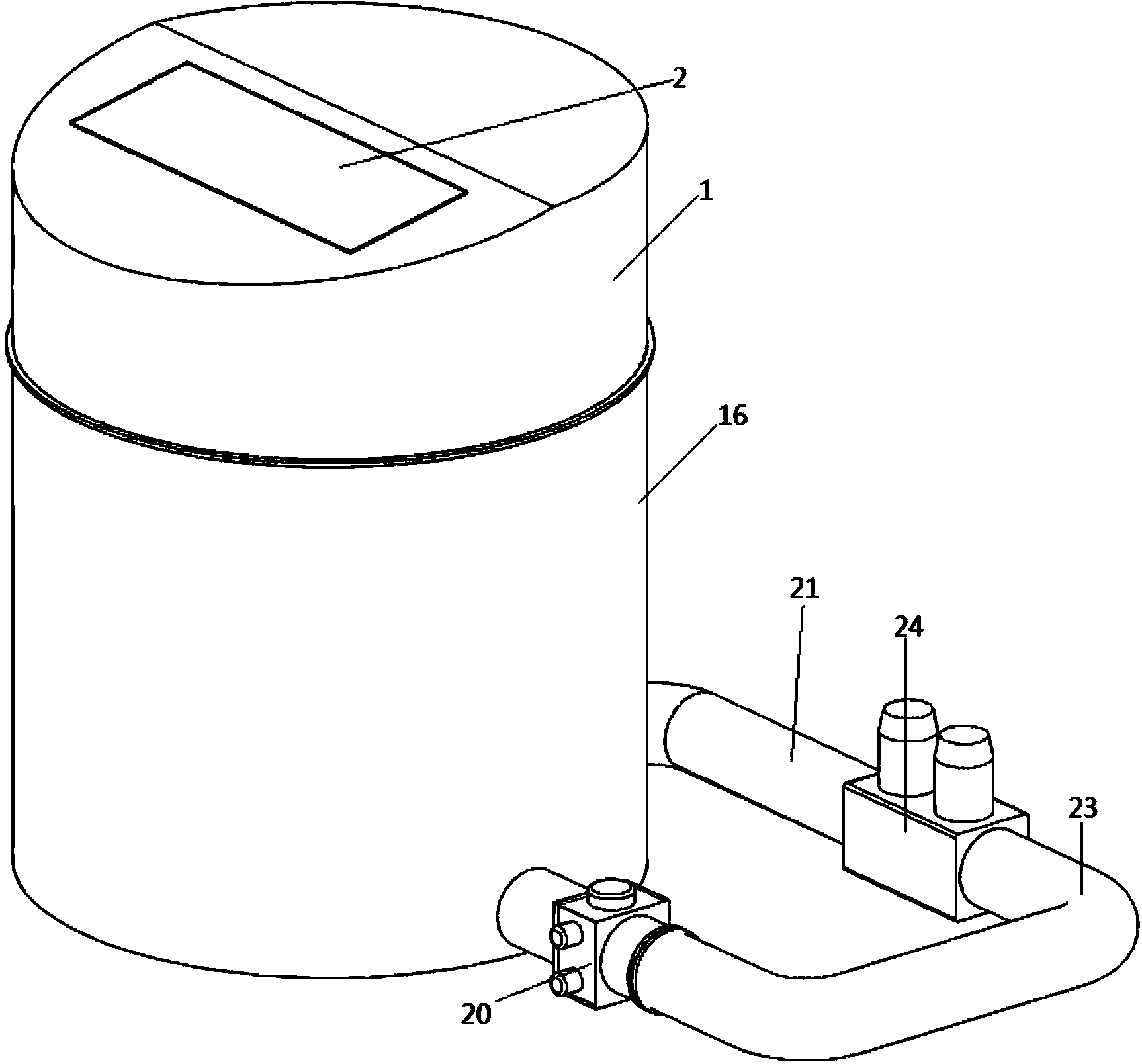

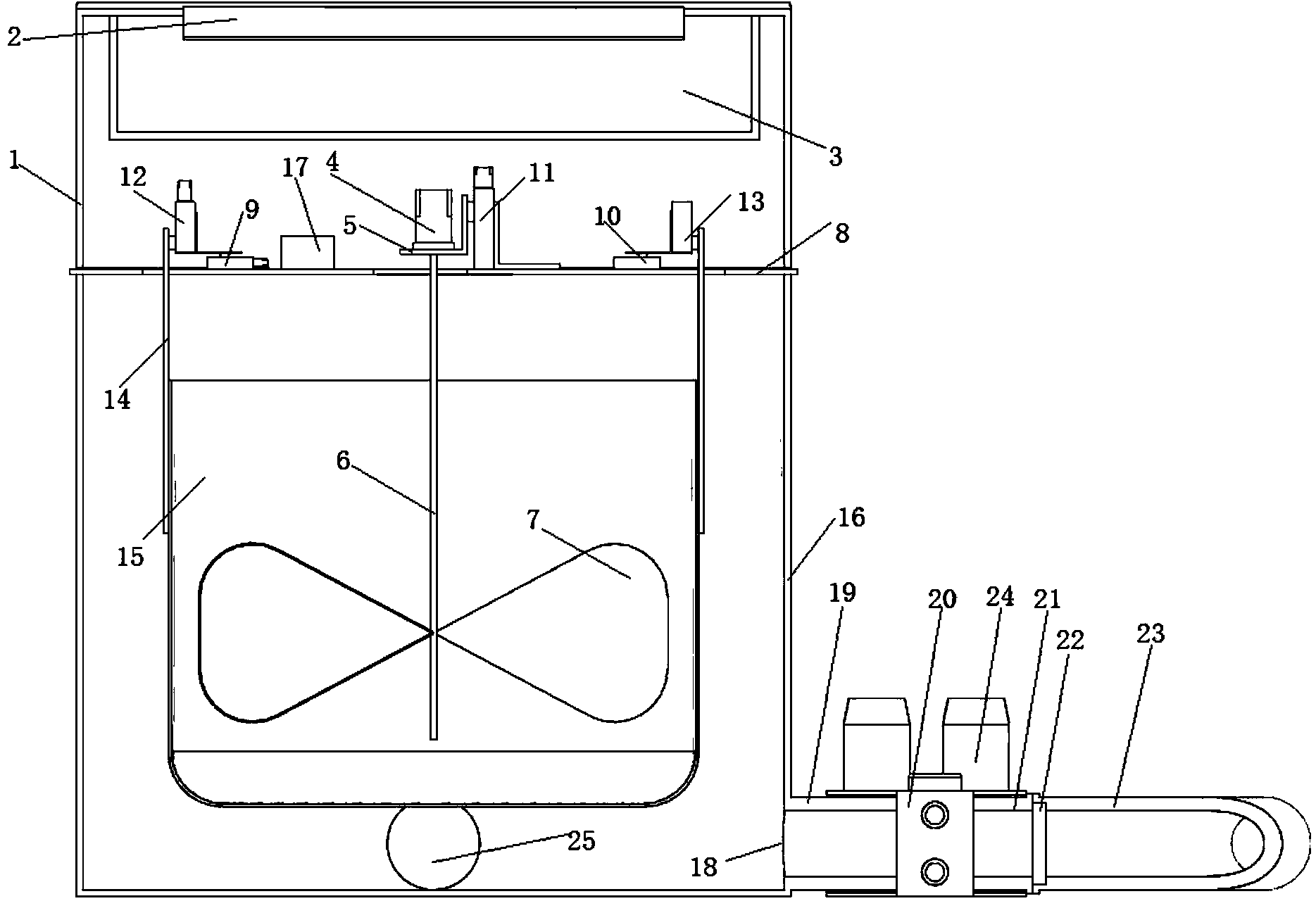

[0013] Referring to the accompanying drawings, the vegetable washing machine with self-cleaning function includes an outer cylinder 16, an upper cover 1 is provided at the mouth of the outer cylinder 16, and a control panel 2 is provided on the top of the upper cover 1, and the control panel 2 is installed in the electric motor inside the upper cover 1. On the control box 3, the main motor 4 is installed on the upper cover bottom plate 8 below the electric control box 3 through the linear motor assembly 11 in the vertical direction of the impeller and the connecting sheet metal 5, and the main motor 4 is installed with the impeller 7 through the impeller shaft 6, and the upper cover bottom plate 8 Both sides are respectively installed with an inner cylinder horizontal linear motor assembly 9 and an inner cylinder lateral movement guide rail assembly 10, an inner cylinder vertical direction linear motor assembly 12 is installed on the inner cylinder horizontal linear motor assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com