Low-power two-phase alternating current frequency conversion system and electromotor thereof

A technology of AC frequency conversion and three-phase motor, which is applied in the direction of AC motor control, irreversible DC power input conversion to AC power output, control system, etc., and can solve the problems of undersymmetry, large number of inverter circuit units, efficiency and vibration noise issues such as levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

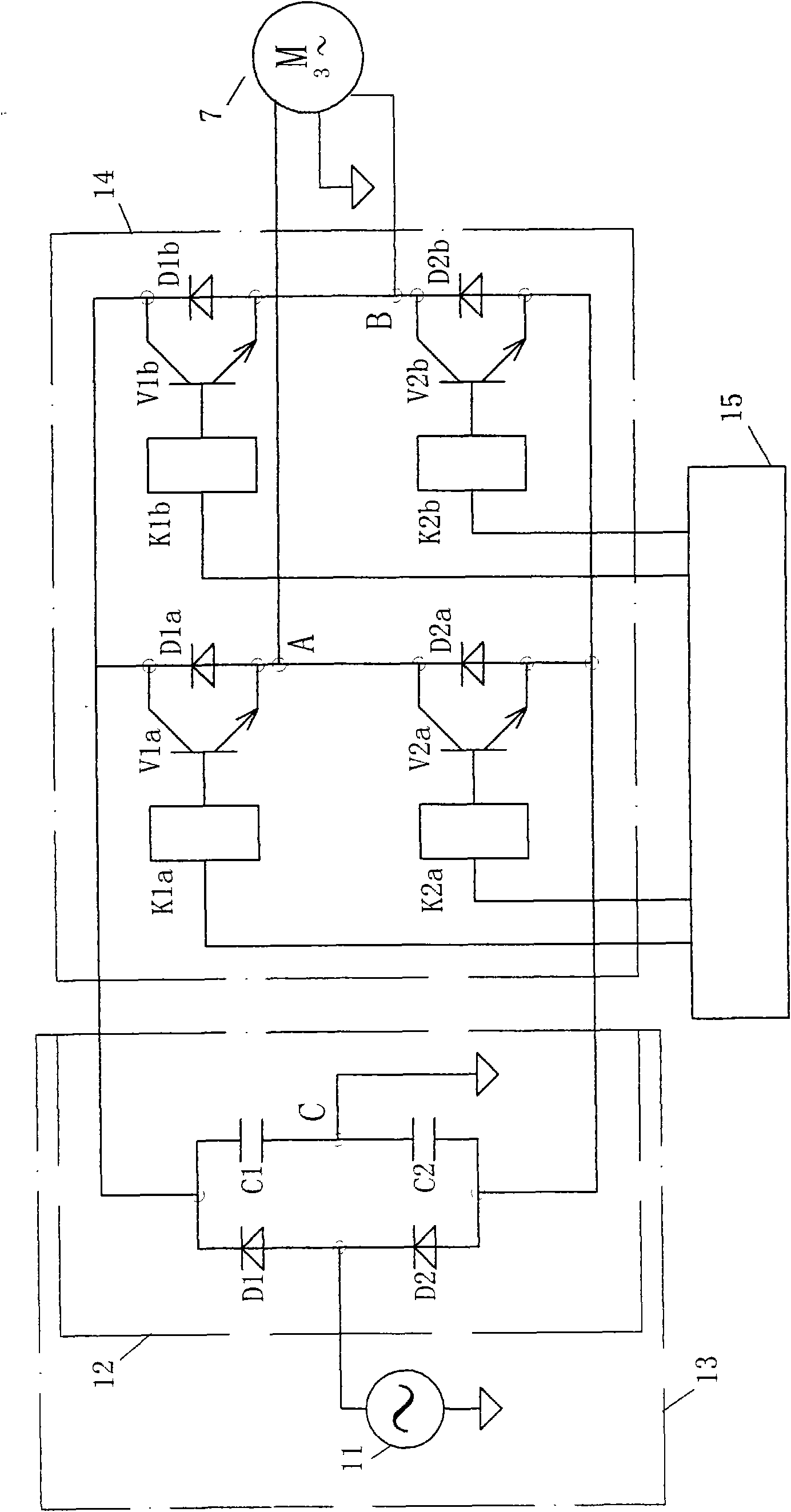

[0012] The frequency conversion drive system of the embodiment of the present invention is as figure 1 As shown, it is mainly composed of a motor 7 and a control device 10 .

[0013] The control device 10 includes: a DC power supply 13 composed of an AC power supply 11 such as 220V50HZ from the power grid, and a rectifying and filtering circuit 12 that is connected to its output and rectifies the AC power supply 11 and converts it into a DC voltage; at the output of the DC power supply terminal connected inverter circuit 14. The motor 7 is connected to an output terminal of the inverter circuit 14 . In addition, the inverter circuit 14 is connected to and controlled by the control mechanism 15 . This is a typical control device of the AC-DC-AC indirect conversion method, but it is not limited to this, and it may be a control device of the AC-AC direct conversion method without a rectification filter circuit.

[0014] The rectifying and filtering circuit 12 includes: a recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com