Four-roller finishing mill

A technology of finishing mills and racks, applied in metal rolling, etc., can solve the problems of high manufacturing costs, waste of resources and capacity, and inability to meet needs, and achieve the effects of simplifying operations and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

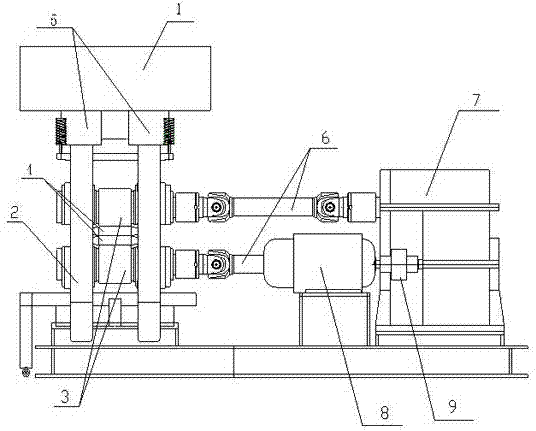

[0023] Such as figure 1 As shown, the four-high finishing mill of this embodiment includes: a frame 2, a motor 8, a composite gearbox 7 connected to the motor 8 through a coupling 9, and two universal joint shafts 6 connected at one end to the composite gearbox 7 1. Two supporting rollers 3 arranged in parallel connected with the other end of the universal joint shaft 6; two working rollers 4 are arranged in the middle of the two supporting rollers 3; a feeding pressure plate is arranged between the working rollers 4 (not shown in the figure ); the upper part of the frame 2 is equipped with a depressing device 5; the depressing device 5 includes a depressing motor, a worm wheel and a worm; the worm is fixed on the frame 2 through a nut; a pressure sensor is provided at the bottom of the worm; system; the worm gear is connected with a rotary encoder; the output end of the rotary encoder is connected to the control system.

[0024] Frame 2 top, the top of depressing device 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com