Cam spring plate mechanism

A technology of cam spring and spring plate, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing, etc., can solve the problems of parts processing deformation, etc., and achieve the effect of easing the action process, good effect, and changing the swing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

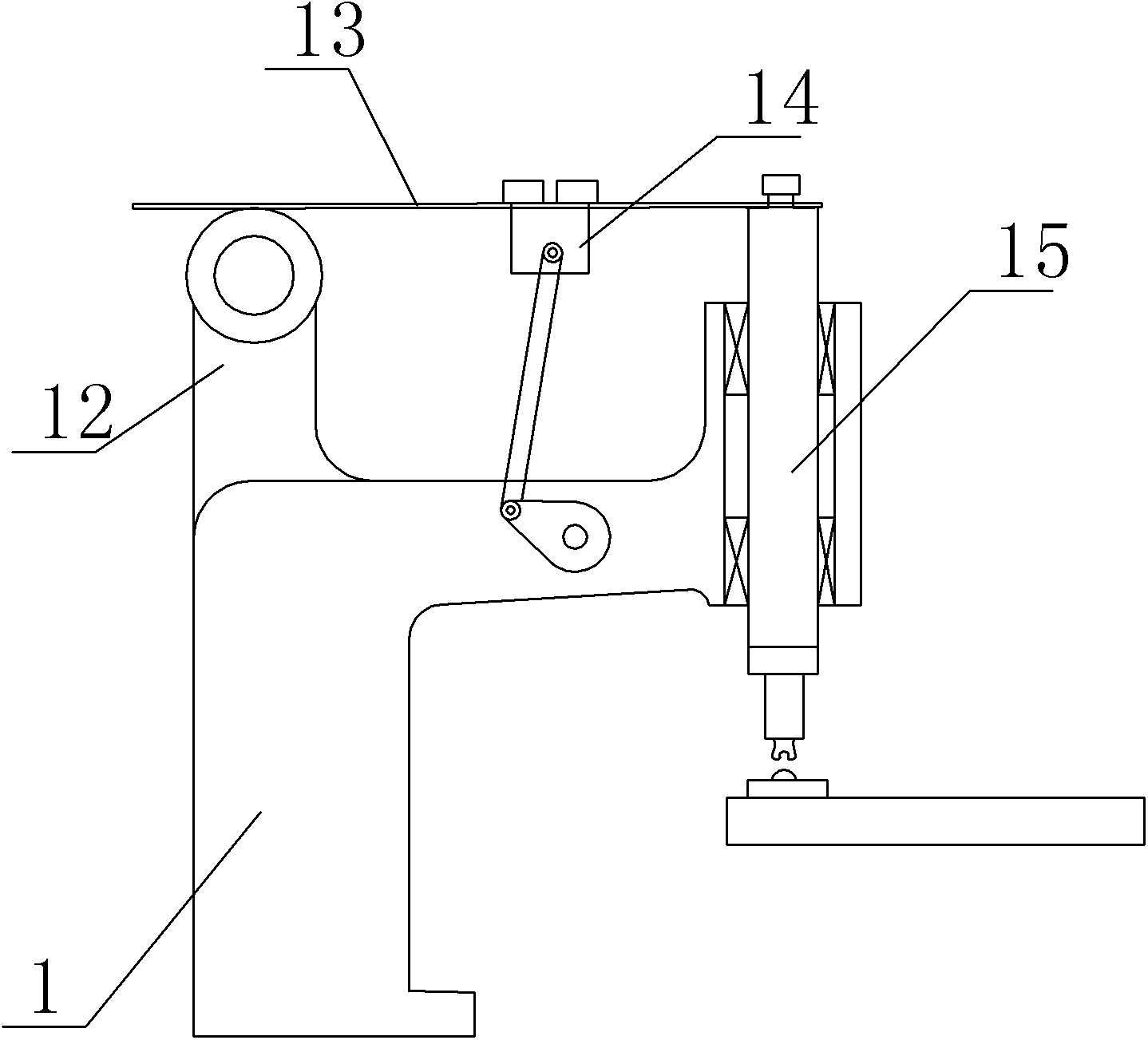

[0009] according to figure 1 As shown, the cam spring plate mechanism in the embodiment of the present invention includes a frame 1, on which a spring plate 13, a clamp seat 12 for clamping the spring plate 13, and a straight rod connected by bolts to one end of the spring plate 13 are arranged on the frame 1 15 and the cam between the clip seat 12 and the straight rod 15, the frame 1 is provided with a sleeve at one end, the straight rod 15 moves axially along the sleeve, the joint between the straight rod 15 and the spring plate 13 is provided with rubber, and includes a clamp Holding the iron block 14, the middle part of the spring plate 13 is fixed to one end of the clamping iron block 14, the other end of the clamping iron block 14 is hinged to one end of the connecting rod, the other end of the connecting rod is hinged to the cam, and the cam rotates on the frame. You can adjust.

[0010] What is described above is only an embodiment of the present invention, and common...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com