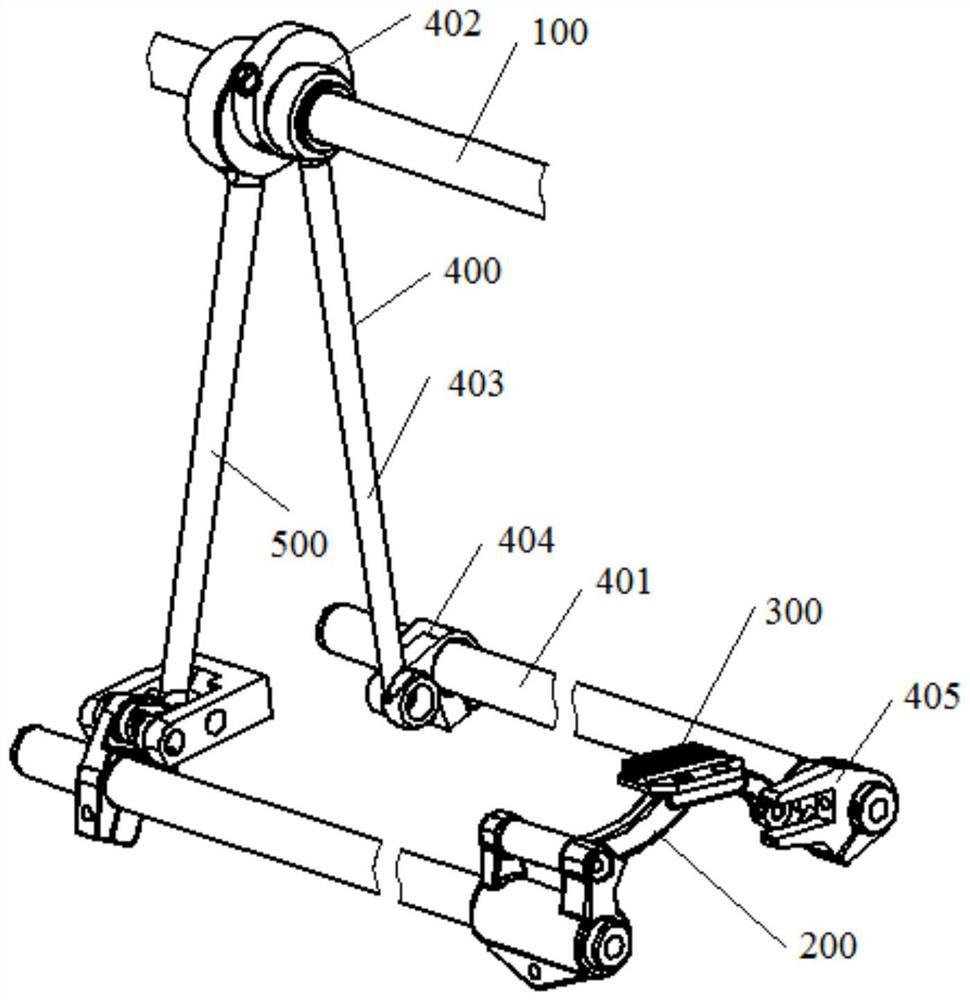

Feed dog lifting height adjustable mechanism and sewing machine

A feed dog and height technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of increasing the height of the feeding dog, affecting the sewing quality, reverse, and back dragging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

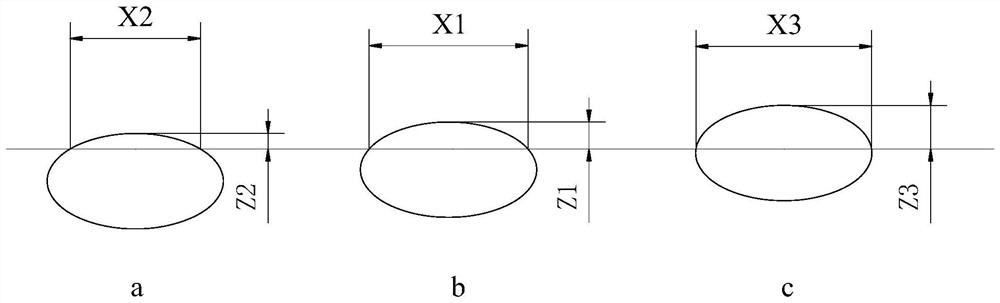

[0072] like Figure 10 and Figure 11 As shown, the second embodiment of the tooth lifting eccentric adjustment assembly 70 includes a ratchet 71, an adjusting slide 72 with a ratchet portion 721 at the lower end, an adjusting eccentric wheel 73, a small eccentric wheel 77, a fixed wheel 78, and a tooth lifting adjustment button 76, The ratchet 71 , the adjusting sliding piece 72 , the adjusting eccentric 73 , the lifting eccentric 51 and the fixed wheel 78 are arranged along the axial direction of the main shaft 10 from left to right. Wherein, the ratchet 71 and the fixed wheel 78 are all set on the main shaft 10 by screws; the left end of the ratchet 71 is provided with a ring of ratchets; Located in the first chute 731 and slidingly matched with the first chute 731; the adjusting slide 72 is provided with a long groove, and the extending direction of the long groove is consistent with the extending direction of the first chute 731, and the adjusting slide 72 When sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com