Machining method for ultra-thin rod products and special jig

A processing method and technology of thin rods, which are applied in the direction of manufacturing tools, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems that ultra-thin rods cannot be produced and the quality of processed products is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

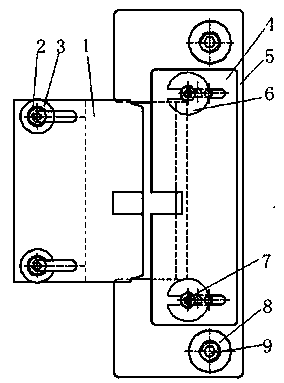

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the specific embodiments.

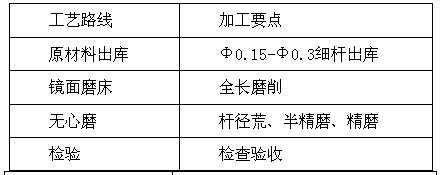

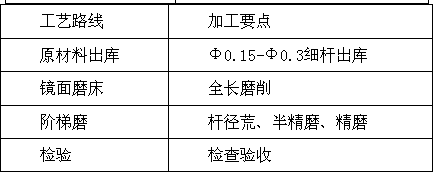

[0025] A kind of superfine rod product processing method, concrete technology such as figure 2 shown, including the following steps:

[0026] (1) Φ0.15-Φ0.3 thin rod materials are cut off after leaving the warehouse;

[0027] (2) Full-length processing and grinding with a mirror grinder;

[0028] (3) Use a stepped grinder equipped with a special tool for processing to carry out crude extraction, semi-finish grinding, and fine grinding, among which

[0029] Raw extraction: the rotation speed of the grinding wheel is 2000 rpm, the rotation speed of the guide wheel is 200 rpm, and the processing allowance of the rod is 0.15mm;

[0030] Semi-finishing: the rotation speed of the grinding wheel is 2000 rpm, the rotation speed of the guide wheel is 200 rpm, and the pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap