Process and apparatus for direct crystallization of polymers under inert gas

A technology of inert gas and polymer, applied to the method of using atmospheric pressure to chemically change substances, the method of granulating raw materials, chemical instruments and methods, etc., which can solve economic disadvantages and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

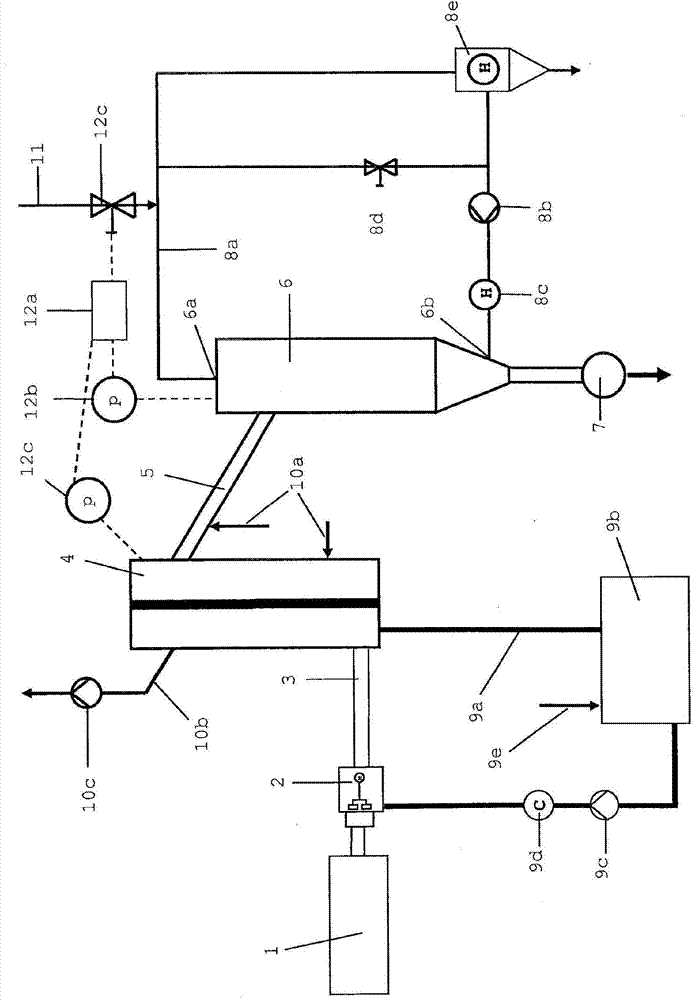

[0095] figure 1 The plant has a reactor 1 for preparing a polymer melt. Here, it is a reactor in which the melt polymerization takes place and thus prepolymers are produced from monomers. Alternatively, reactor 1 may also be a device for melting solid products such as prepolymers. In this case, the reactor 1 may be, for example, an extruder.

[0096] The molten material is transferred to the granulation unit 2 . Pellets are produced from the molten material in a known manner in a granulator 2 . For example, the granulator can be an underwater granulator (such as figure 1 shown) or can be an underwater strand granulator. In this case, the granulation takes place under water. The resulting granulated granules are simultaneously cooled in the granulator 2 . But as previously mentioned, the cooling does not allow such a strong drop that the granulated particles cool below their glass transition point (ie below the viscosity temperature). This can be achieved by using heate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com