Multi-printing-head 3D (3-dimensional) printing system based on layer working network

A 3D printing and printing head technology, applied in the direction of printing device, digital output to printing unit, printing, etc., can solve the problem of low manufacturing efficiency of 3D printing of large-scale models, and achieve the effect of improving the efficiency of 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

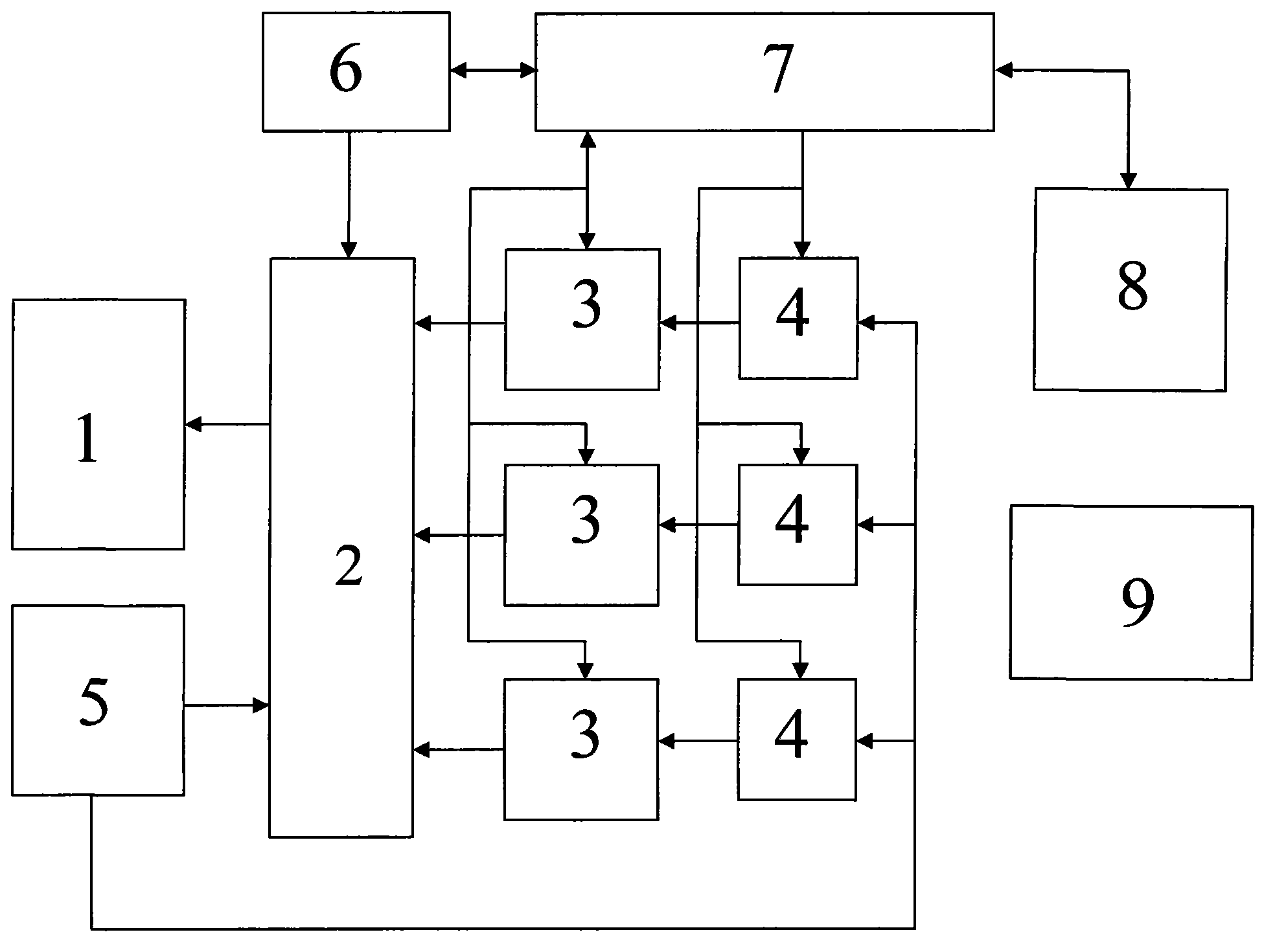

[0009] See accompanying drawing 1: a kind of multi-print head 3D printing system based on layer working grid, including machine bed, layer plane rail frame mechanically connected with the machine bed, and layer plane rail frame mechanically connected The printing head moving device, the printing head mechanically connected with the printing head moving device, the material conveying device mechanically connected with the layer plane rail frame and the print head, the scanning machine mechanically connected with the layer plane rail frame Measuring device, a control system electrically connected with the layer plane rail frame, print head moving device, print head, and scanning measurement device, a computer system electrically connected with the control system, it also includes 3D printing control software, layer The plane guide rail frame is installed on the machine bed, and the control system moves along the machine bed according to the layer position movement command of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap