A multi-purpose coil spring mounting seat

A technology of coil springs and mounting seats, which is applied in the direction of elastic suspension, transportation and packaging, suspension, etc., can solve the problems of increasing the number of body parts, improving production efficiency, and inconvenient welding operations, so as to improve rigidity and strength and reduce parts Quantity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

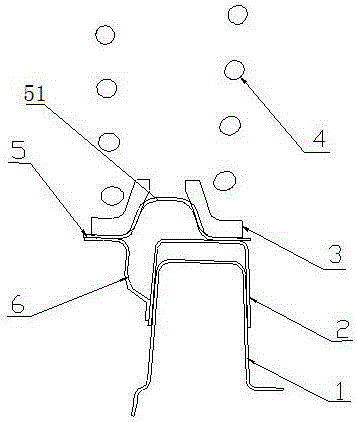

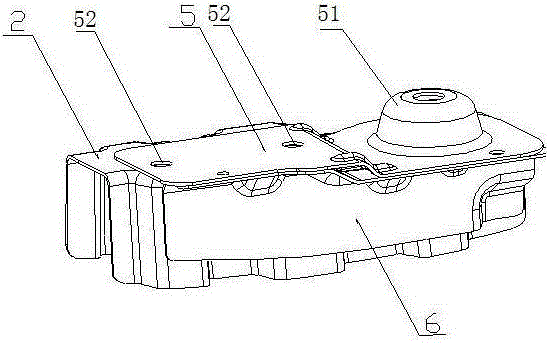

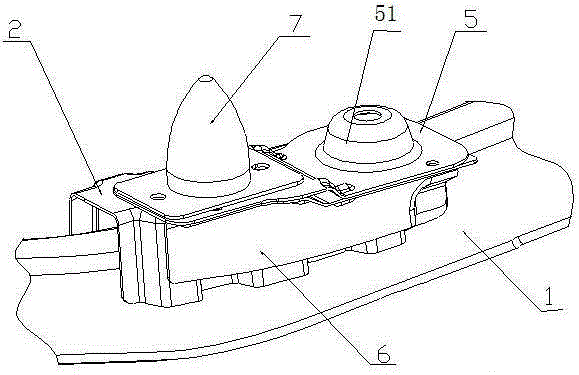

[0016] see Figure 1 to Figure 3 The shown multi-purpose helical spring mounting seat comprises a strip-shaped positioning plate 5, a mounting bracket 2 welded and fixed to one side of the positioning plate 5 below, an upper end welded to the other side below the positioning plate 5 and the lower end is welded to the positioning plate 5. The mounting bracket 2 is a connecting piece 6 welded and fixed on one side, and the connecting piece 6 plays a role of structural support and reinforcement for the side of the positioning plate 5 extending out of the side beam 1 of the vehicle body, so that the positioning plate 5 is under the reciprocating action of the alternating load Has sufficient fatigue strength.

[0017] The positioning plate 5 provides a support surface for the installation and positioning of the coil spring 4 and the buffer seat 7, and a protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com