Novel ground condition adaptation type bouncing power leg of hopping robot

An adaptable and robotic technology, applied in the field of jumping robots, can solve the problems of the jumping height of the robot that affects the conversion rate of energy, the power legs cannot touch the ground, and the utilization rate of spring energy is low, and achieves compact structure, convenient control, and high jumping height high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the drawings and specific embodiments.

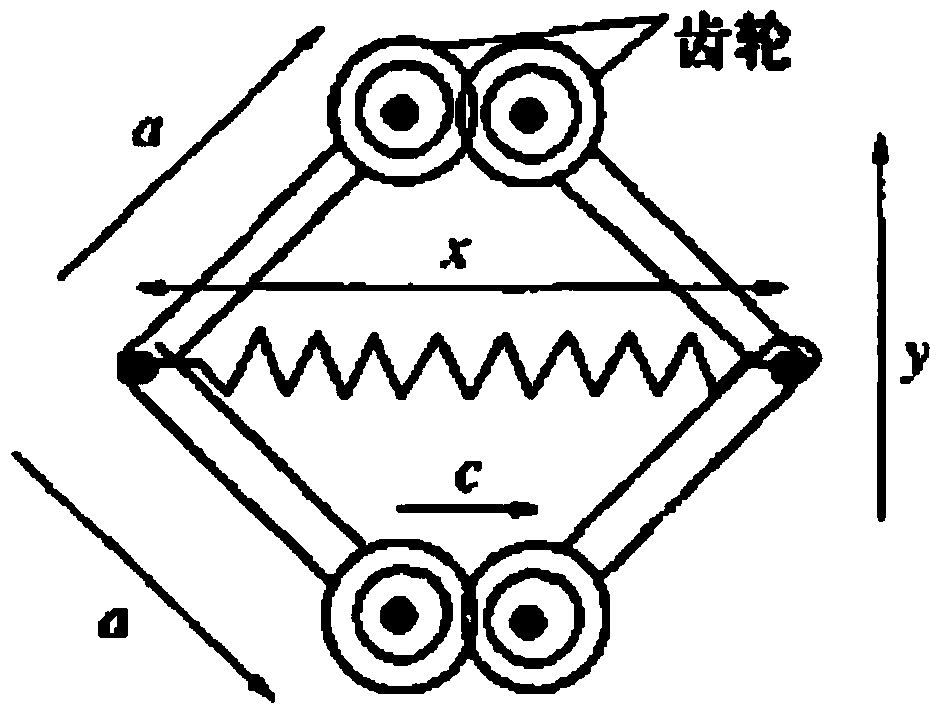

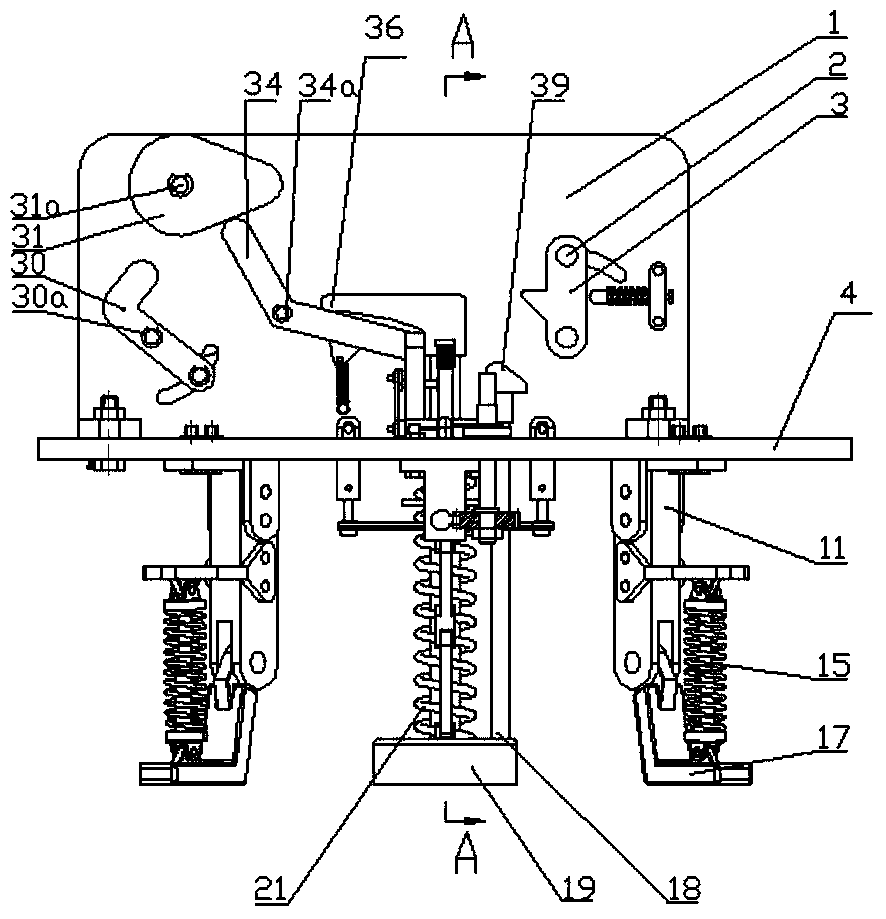

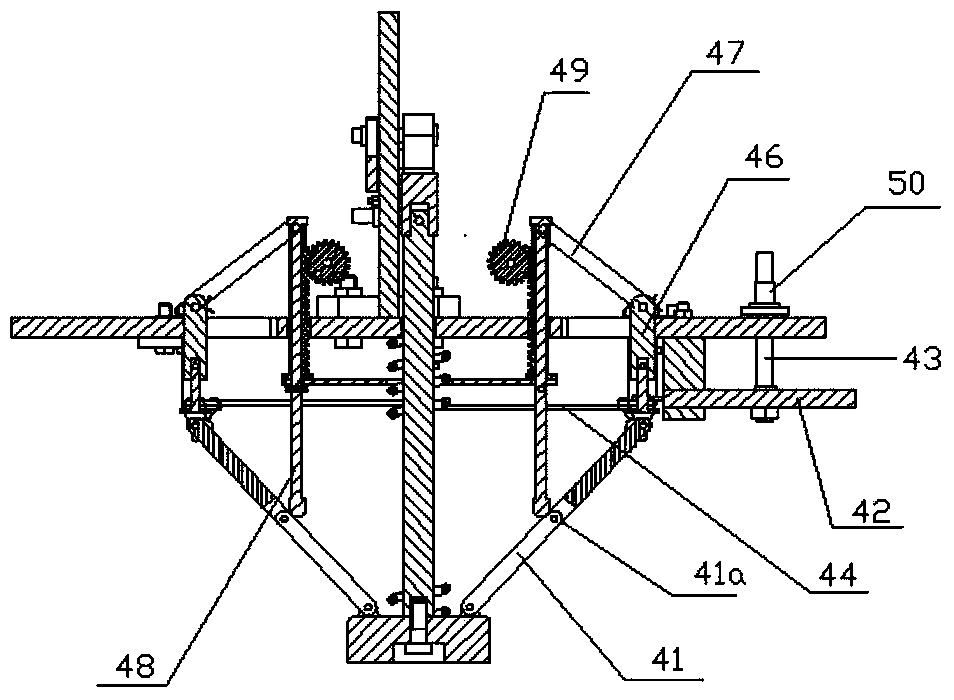

[0030] The bounce power leg of the new terrain adaptive jumping robot mainly includes power spring 21, dead-point push rod guide sleeve, dead-point push rod 48, foot spring 15, kick foot 19, support plate 4, gear a, rack a, Gear b, rack b, parallelogram mechanism 44, etc.

[0031] See Figure 2-9 , A new type of terrain-adaptive jumping robot, including a horizontal support plate 4, below which is fixed 3-4 support legs, the center of the support plate 4 is provided with a bounce leg, the bounce leg includes a kick 19 , The upper part of the pedal 19 is connected with the spring guide post and the tripping rod 18. The spring guide post is sheathed with a power spring 21. The lower end of the power spring presses the pedal 19, and the upper end abuts the support plate 4, and the upper end of the tripping rod 18 is provided with The tripping contact 39, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com