Method and device for stabilizing heavy metal through pyrolysis of sludge

A heavy metal and pyrolysis technology, applied in pyrolysis treatment of sludge, removal of solid waste, vaporization of by-products, etc., can solve the problems of high sludge treatment cost, waste of funds, large input level, etc., and reduce energy consumption. requirements and disposal costs, improve overall economics, avoid high disposal fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

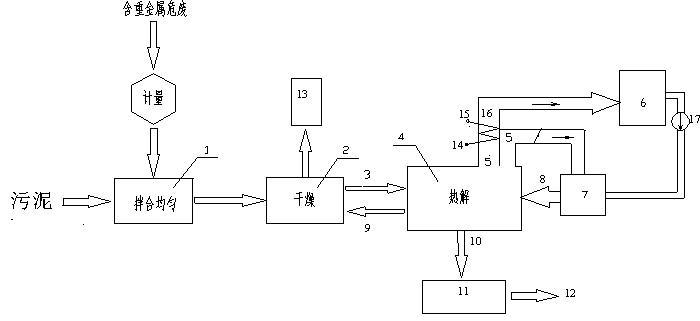

[0025]The dry basis calorific value of sewage sludge in a certain city is 15500KJ / kg, the water content is 82%, and the various heavy metals contained in itself are not high. Another batch of incineration fly ash needs to be processed. The incineration fly ash contains 2800ppm of Pb, 400ppm of Cd and 3.6ng / g-I TEQ of dioxin, which belongs to hazardous waste. During the treatment, fly ash is added according to 20% of the dry weight of the sludge, and the dry basis calorific value of the mixed material is 12400kJ / kg. And add 18kg of sawdust powder / ton of wet sludge; or add 7kg of crushed waste plastics per ton of wet sludge to supplement pyrolysis energy. After repeated mixing and kneading in the tank-type mixer 1 with agitator, it is sent to the dryer 2. The dryer 2 is a rotary drum dryer. The flue gas 9 is in direct contact with the sludge and dried. into the gas purifier 13. After drying, the mixed material 3 enters the pyrolyzer 4. The pyrolyzer 4 is a three-stage heating ...

Embodiment 2

[0027] The dry basis calorific value of a certain sewage sludge is 13000KJ / kg, the water content is 70%, and the various heavy metals contained in itself are not high. Another batch of Cr-containing waste slag discharged from chemical plants needs to be treated. The waste slag has a Cr concentration of 5900ppm, a Cd concentration of 1000ppm, a water content of 40%, and a dry basis calorific value of 5000kJ / kg, which is a hazardous waste. During treatment, add this waste residue according to 5%~10% of the dry weight of the sludge, and the dry basis calorific value of the mixed material is 10900~12600 KJ / kg. Repeated mixing in the tank type mixer 1 with agitator, after stirring evenly, it is sent to the dryer 2, the dryer 2 is a rotary drum dryer, the flue gas 9 is in direct contact with the sludge and dried, and the waste gas is discharged into the gas Purifier 13. After drying, the mixture 3 enters the pyrolyzer 4 again. The form of the pyrolyzer 4 is the same as that of embo...

Embodiment 3

[0029] The dry basis calorific value of a certain sewage sludge is 12000KJ / kg, it has been dried, the moisture content is nearly 0%, and the various heavy metals contained in it are not high. Another batch of sludge containing heavy metal cadmium Cd needs to be treated; the dry basis calorific value of the cadmium-containing sludge is about 3000KJ / kg, which cannot sustain combustion, the concentration of Cd is 2900ppm (dry basis), and the water content is 60%. Hazardous Waste. During treatment, add this waste residue according to 5%~10% of the dry weight of the sludge, and the dry basis calorific value of the mixed material is 11100~11550 KJ / kg. Add a small amount of water to the tank-type mixer 1 with agitator to thicken the dry sludge, mix it with cadmium-containing mud repeatedly, and after mixing evenly, send it to the dryer 2. The dryer adopts a rotary disc-type indirect dryer. , the dried material 3 is sent to the pyrolyzer 4, the pyrolyzer is a three-stage rotary heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap