Horizontal roll table type glass tempering cooling method during glass tempering production

A glass tempering and cooling method technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as unstable glass quality, unbalanced glass force, and difficulty in ensuring accuracy, and achieve accuracy improvement and force balance , easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

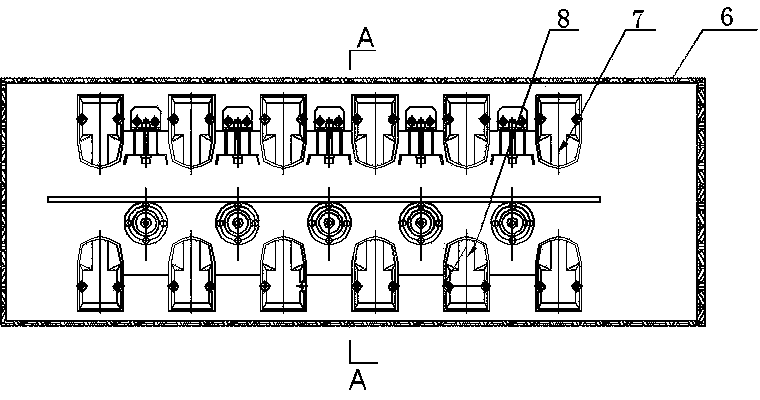

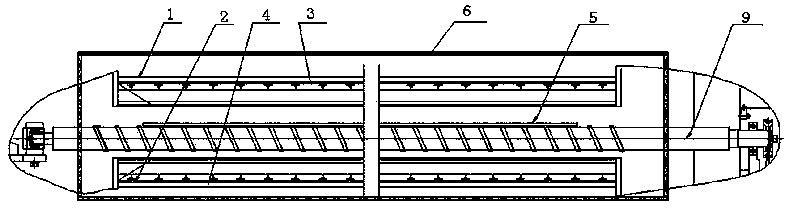

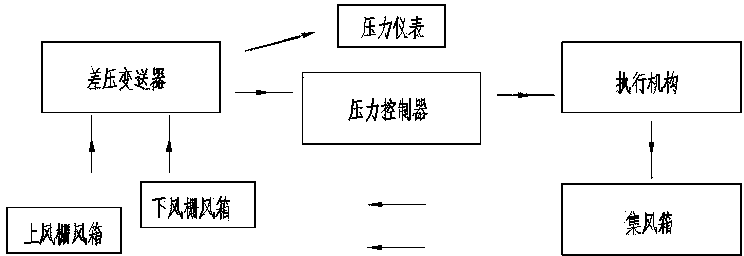

[0016] As shown in the figure, the horizontal roller glass tempering and cooling method in glass tempering production includes a tempering cooling section for cooling the glass and a roller conveying mechanism for conveying the processed glass. The glass 5 after heat treatment in the heating section passes through the The roller table 9 is sent to the tempering cooling section, which is equipped with an upper air grille 1 and a lower air grille 2 for blowing the upper and lower sides of the glass, the upper air grille 1 and the upper air grille air box 3 are sealed and connected, the lower air grille 2 and the lower air grille The air box 4 is sealed and connected, and the tempered cooling section is also provided with a closed low-temperature chamber 6. In the tempered cooling section, the blowing and cooling process of the glass by the upper and lower air grids is carried out in the low-temperature chamber 6. As the glass passes through the passage of the low-temperature chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com