Air exhaust steel rod tower

A technology of steel rods and rod bodies, which is applied in the field of municipal lighting equipment, can solve the problems of large force and poor discharge performance, and achieve the effects of improving performance, improving reliability, and ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

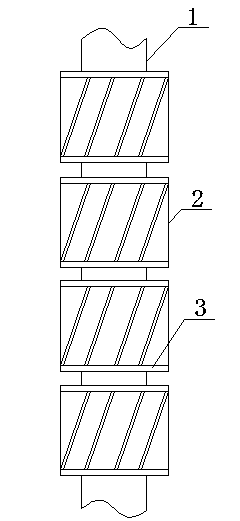

[0013] like figure 1 It is a structural schematic diagram of the present invention, a steel tower for exhausting air, including a rod body 1, which is a hollow tube, and an exhaust device 2 is arranged on the outer surface of the rod body 1. The air exhausters 2 are evenly distributed on the cylindrical surface of the rod body 1 . The blower 2 is a hollow impeller. The air exhauster 2 is sleeved on the rod body 1 . Guard plates 3 are provided on the top and bottom of the air exhauster 2 .

[0014] Put the hollow air exhauster 2 on the rod body 1, and several air exhausters 2 are strung together to form a sheath on the rod body 1. When the rod body 1 is hit by a strong wind, the force contacts the air exhauster 2 on the rod body 1, The air exhauster 2 is blown by the wind and rotates, and at the same time the wind is also taken away along the air exhauster 2, which converts the frontal impact force on the rod body 1 into the rotational kinetic energy of the air exhauster 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com