Oilfield blowout control operation device and method

An operating device and oilfield technology, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the problems of high labor intensity, casualties, large space occupied by the double-arm structure, etc., and achieve displacement posture Strong adjustment ability, reduce blowout loss, and be conducive to the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

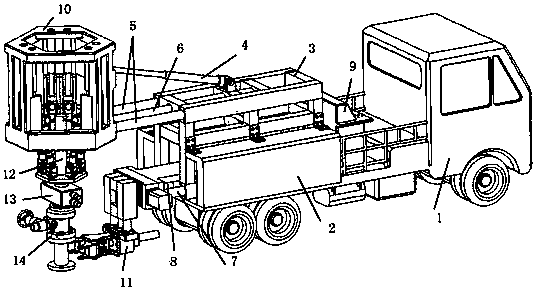

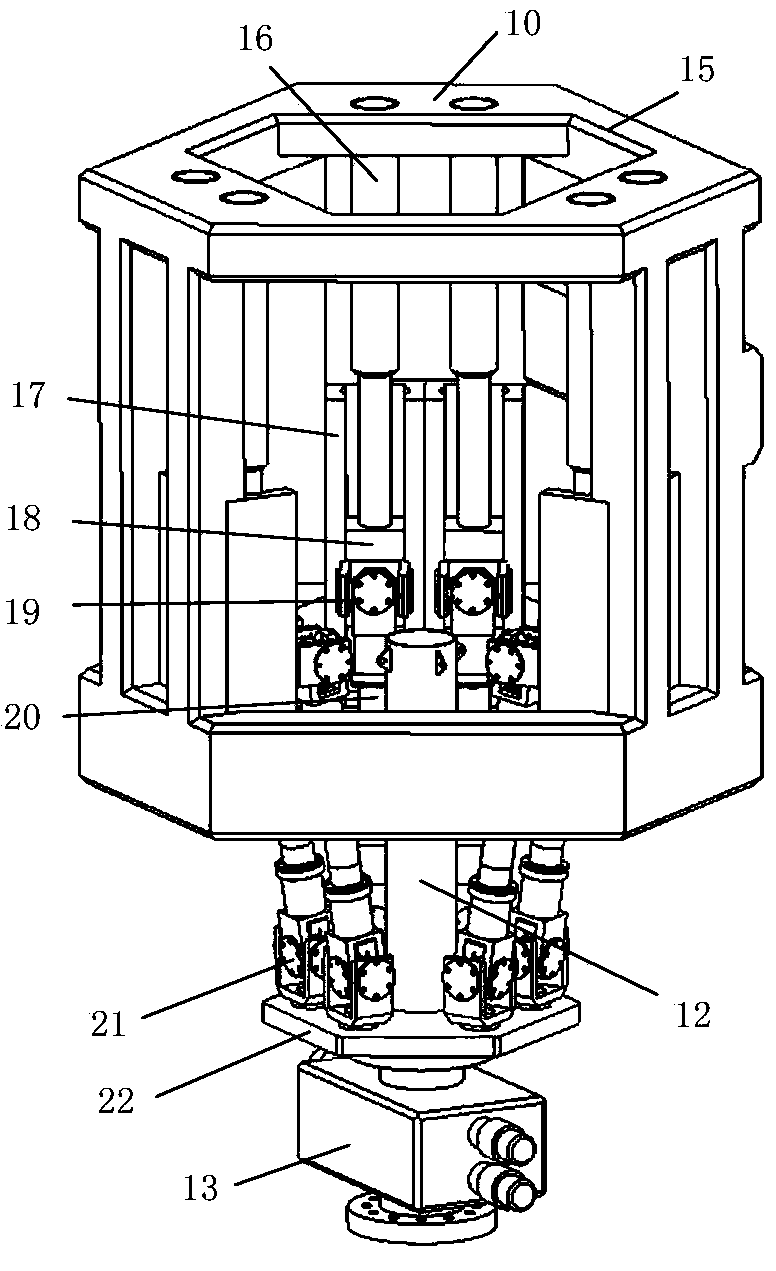

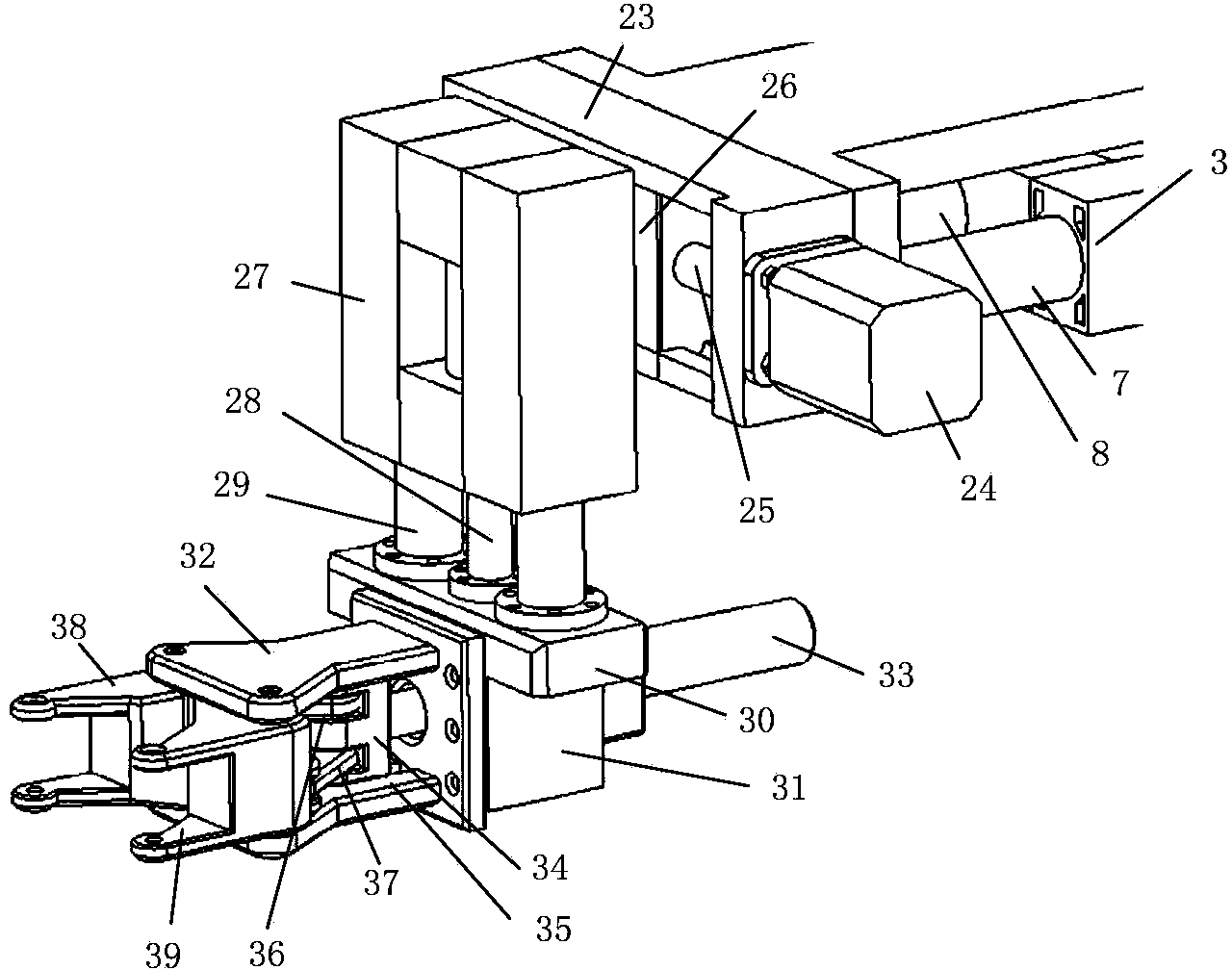

[0023] The present invention will be further described below in conjunction with specific embodiments: see attached figure 1 , figure 2 with image 3 , The oilfield rush injection operation device of the present invention includes a carrier vehicle 1, an auxiliary cylinder 4, an upper guide post guide sleeve 5, a lower guide post guide sleeve 7, a centering attitude adjustment device 10, an anchoring rooting device 11, and other auxiliary connections and drives Device; The carrier 1 is equipped with a frame 3, a hydraulic system 2 and a control console 9. The frame 3 is a steel structure welded and is a double-layer frame; the upper and lower four steel beams are installed with upper guides The post guide sleeve 5 and the lower guide post guide sleeve 7 are respectively matched with their respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com