Deep groove thrust ball bearing or radial-thrust ball bearing acting on two sides

A technology for thrust ball bearings and bearing support, which is applied in the direction of ball bearings, rotating bearings, bearings, etc., and can solve problems such as expensive installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

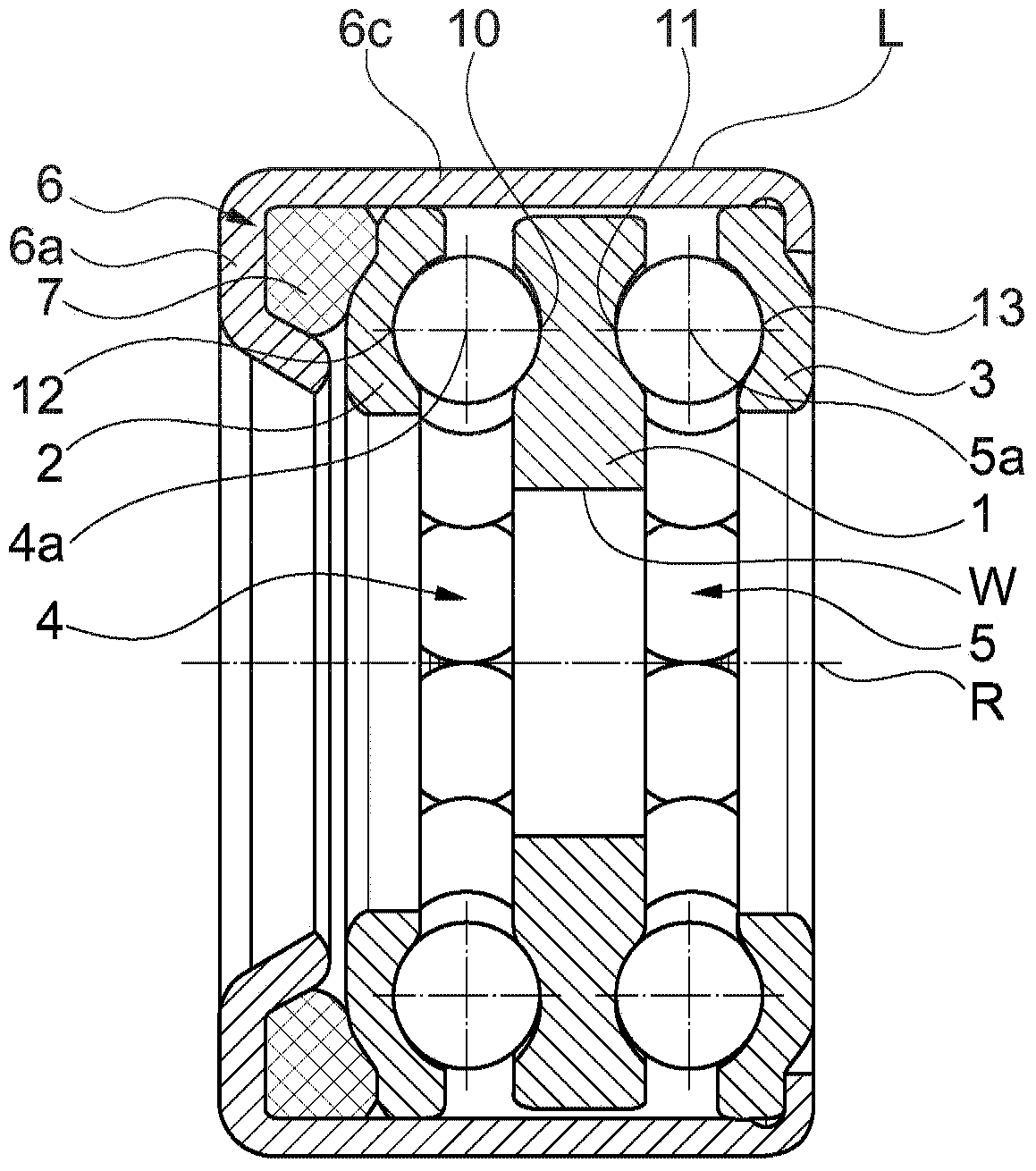

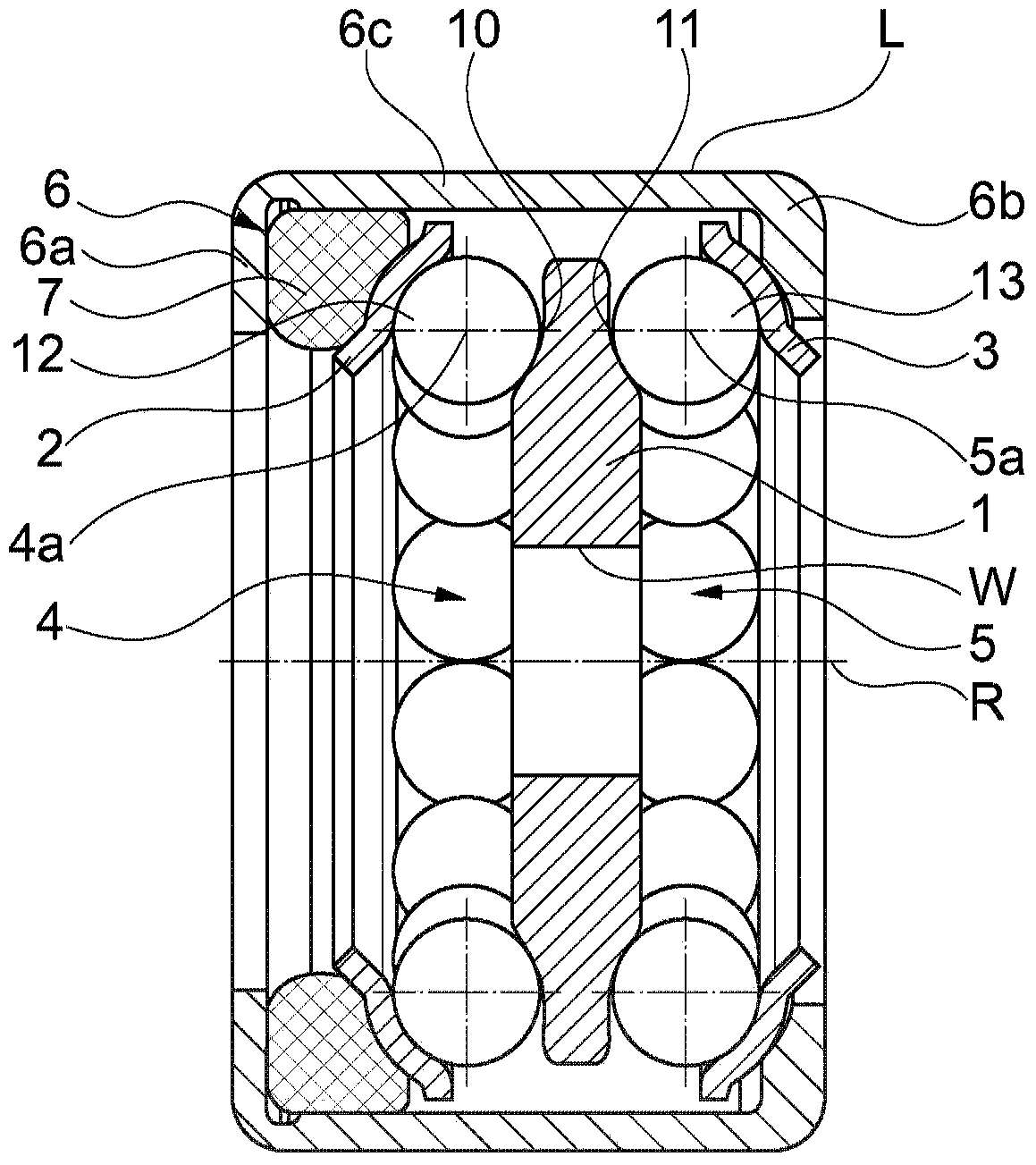

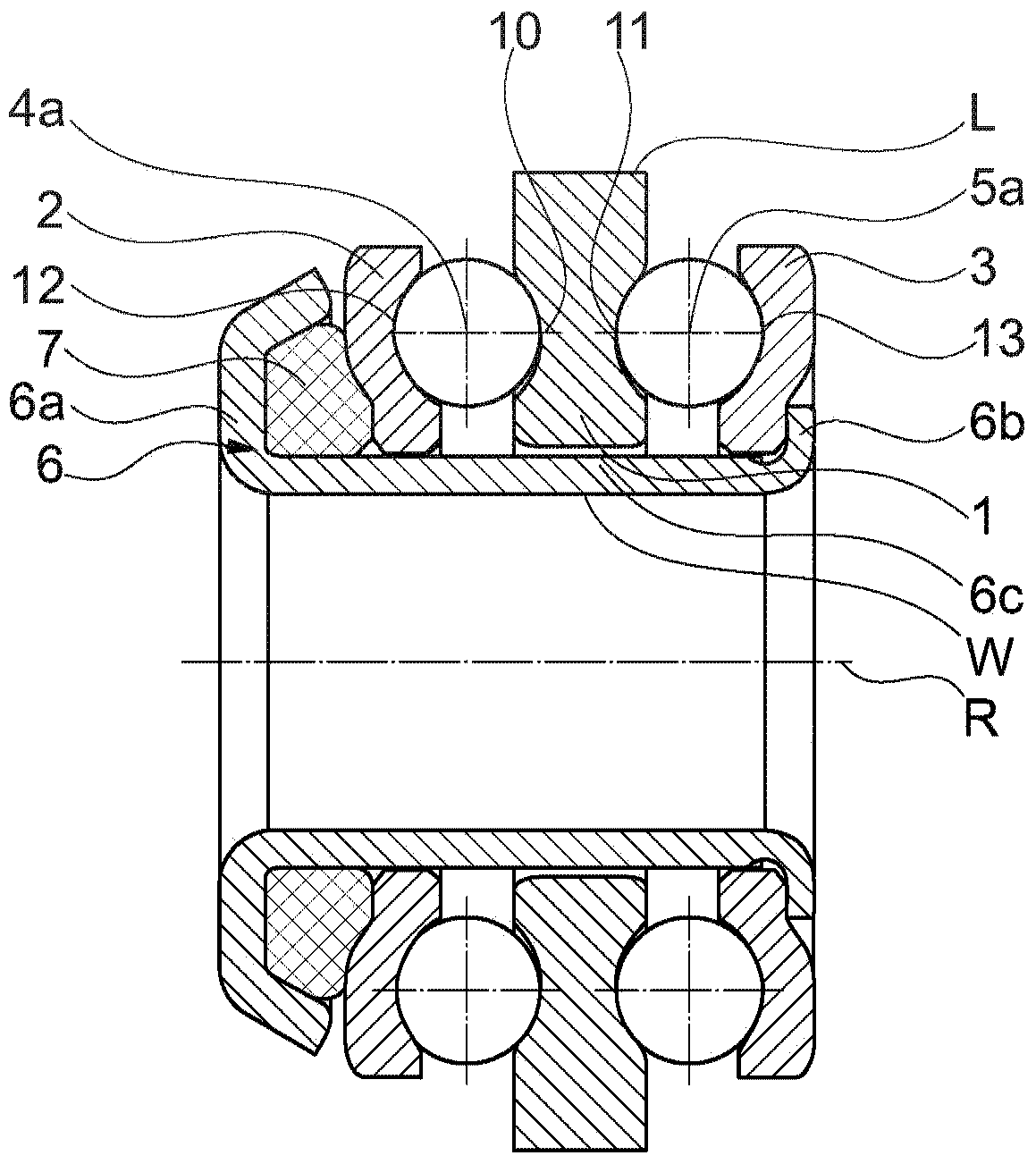

[0044] Figures 1 to 4 Shown are deep groove thrust ball bearings or radial thrust ball bearings acting on both sides, which each have two inner rolling grooves 10, 11, Two outer grooves 12 , 13 and two rows 4 , 5 of bearing balls 4 a , 5 a arranged circumferentially in inner grooves 10 , 11 and outer grooves 12 , 13 . Here, at least one of the outer grooves 12 , 13 is machined into the inner axial side of the outer (axial) running disk 2 , 3 .

[0045] Figure 1 to Figure 4 It is shown here that the bearing also has a sleeve 6 formed axially on both sides with radial edges 6 a , 6 b , in which sleeve an elastic element 7 in the form of a plastic ring made of an elastomer material is inserted. In this case, the sleeve 6 is designed in particular such that it holds all parts 1 , 2 , 3 , 4 a , 5 a , 7 of the bearing and can be pressed in with its outer diameter or pressed in with its inner diameter.

[0046] Figure 1 to Figure 4 The illustration shows that the running disks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com