Medium chain sleeve for amphibious excavator

A technology for excavators and middle sleeves, which is applied in the field of chains, can solve problems such as wear and affect the service life of chains, and achieve the effects of prolonging service life, scientific design, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

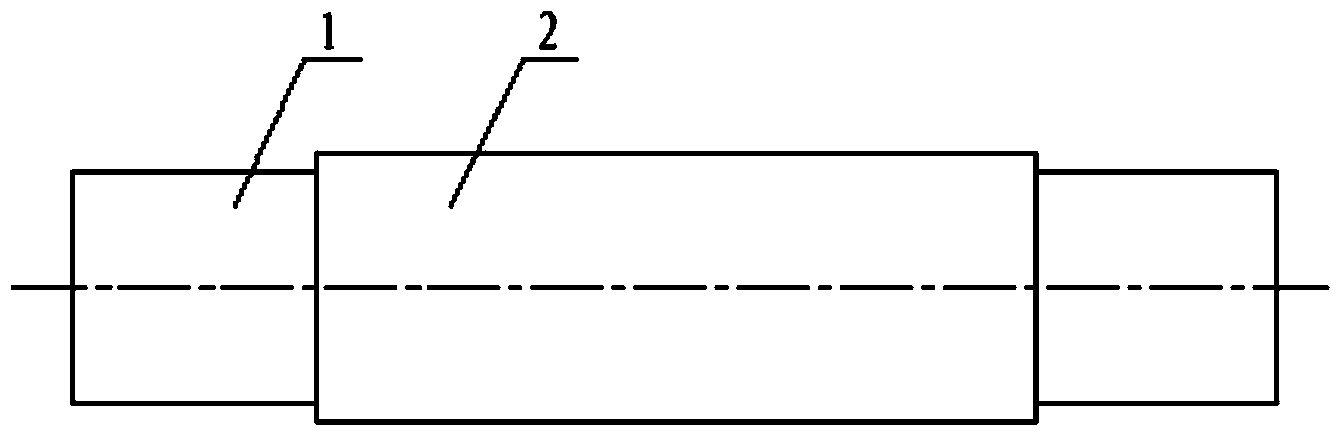

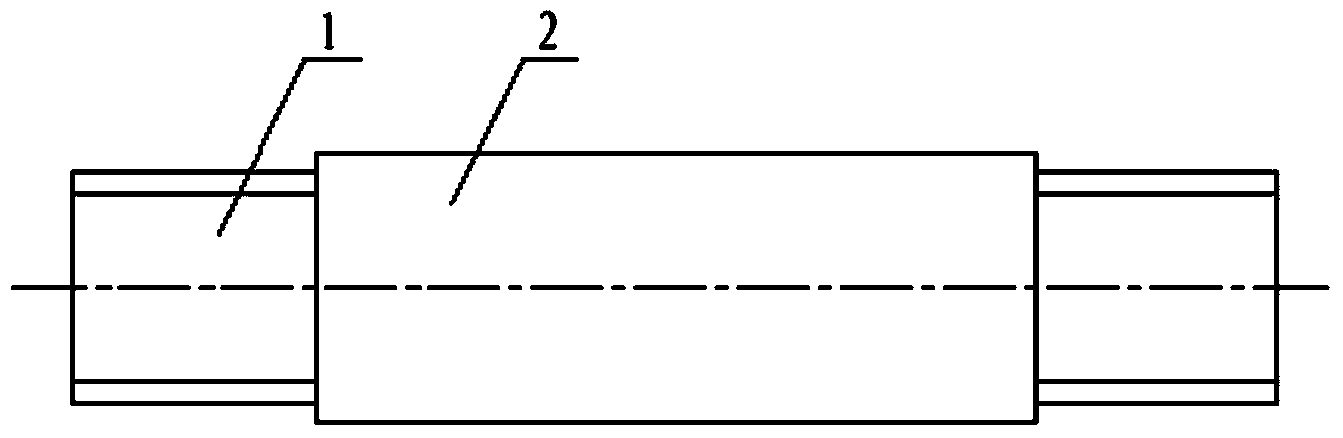

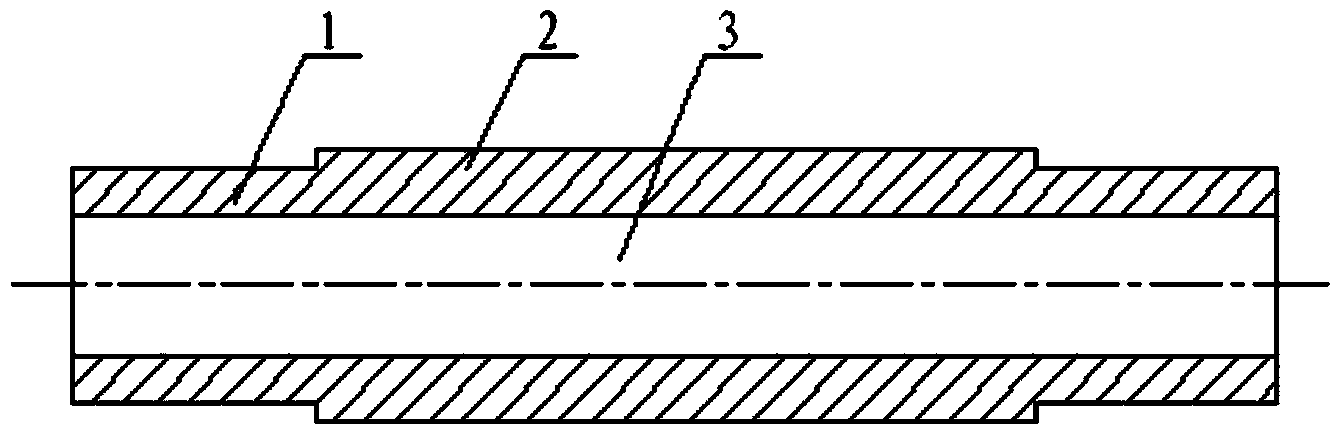

[0014] A chain middle sleeve for an amphibious excavator comprises a cylindrical middle sleeve main body 1, and an axial hole 3 is formed on the shaft center of the cylindrical middle sleeve main body. The innovation point of the present invention is: an outer cover 2 is made coaxially outside the middle part of the main body of the cylindrical middle cover. The upper end surface and the lower end surface of the tubular middle sleeve main body located on the left and right sides of the overcoat are all made into plane 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com