Patents

Literature

45results about How to "Add reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

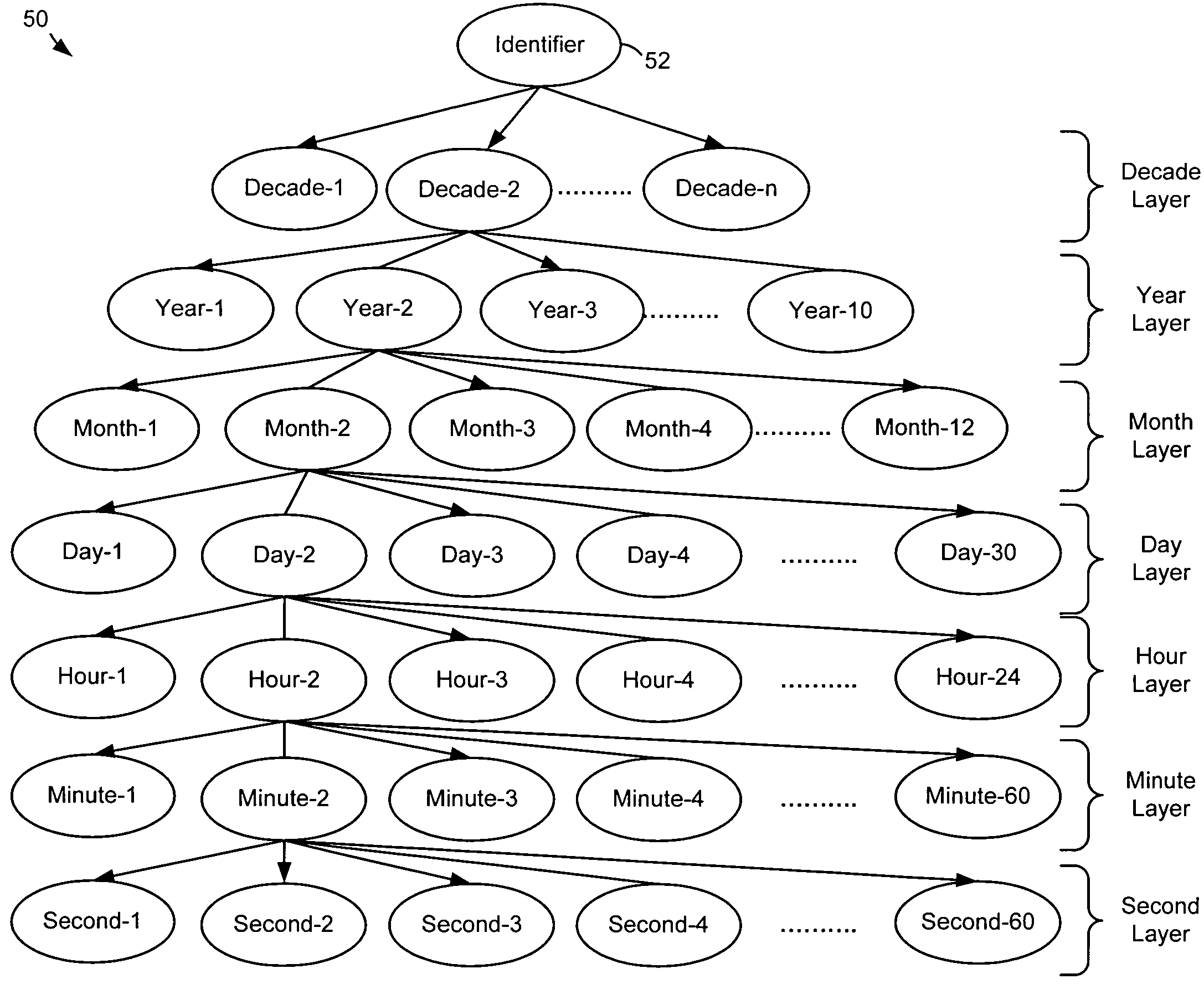

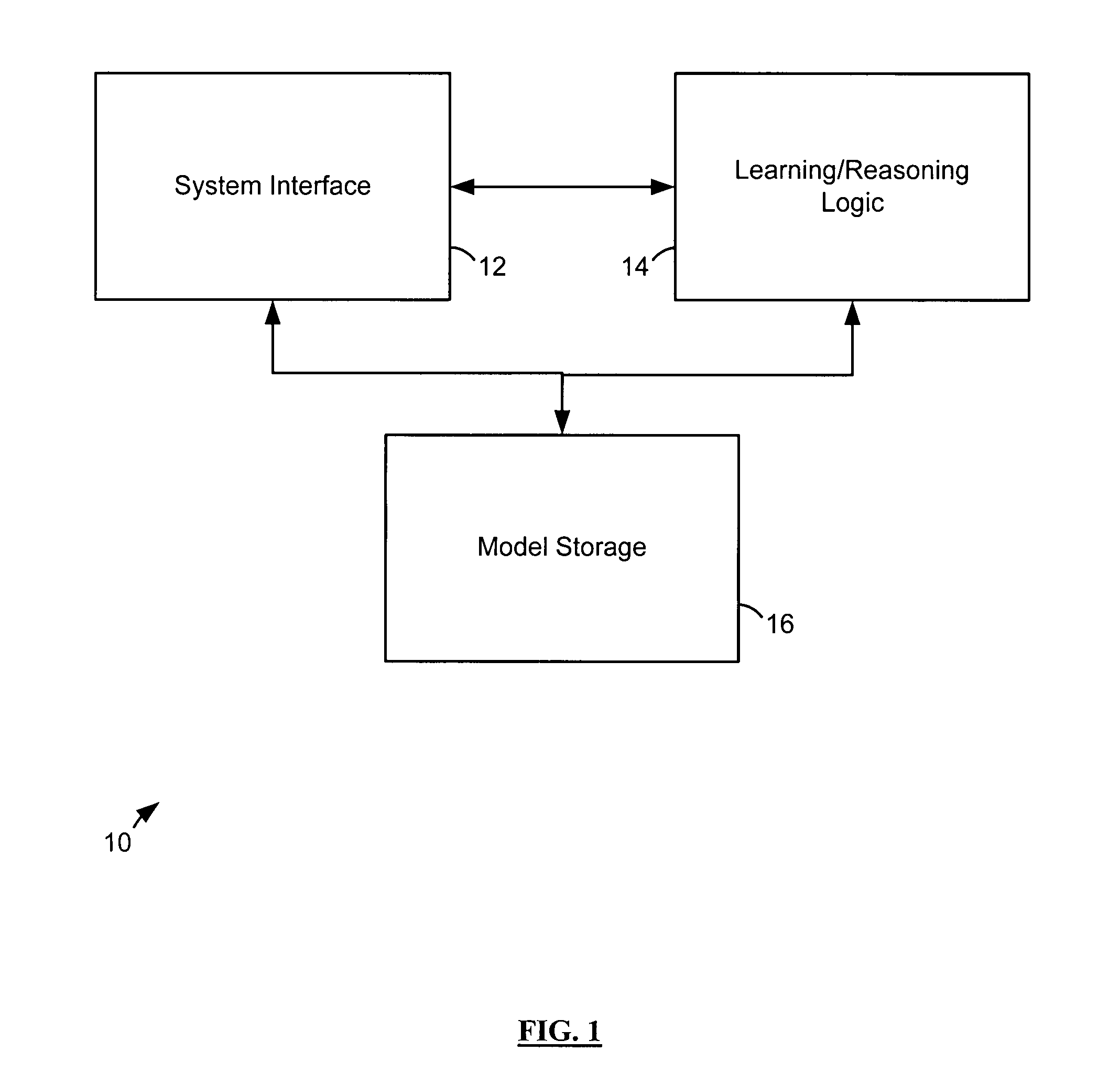

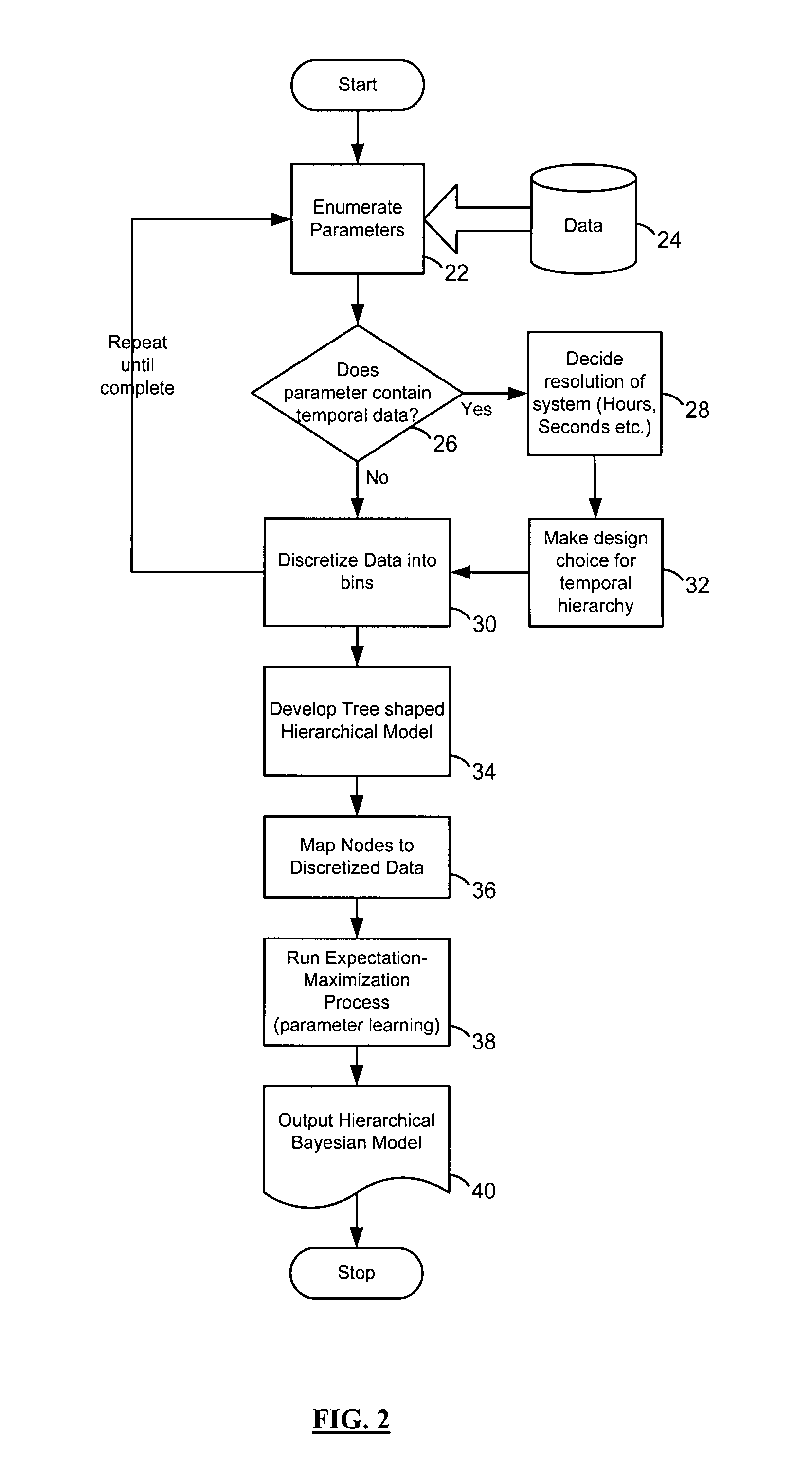

Apparatus and method for learning and reasoning for systems with temporal and non-temporal variables

InactiveUS20080010232A1Easy to learnAdd reasonableChaos modelsNon-linear system modelsTheoretical computer scienceGoal system

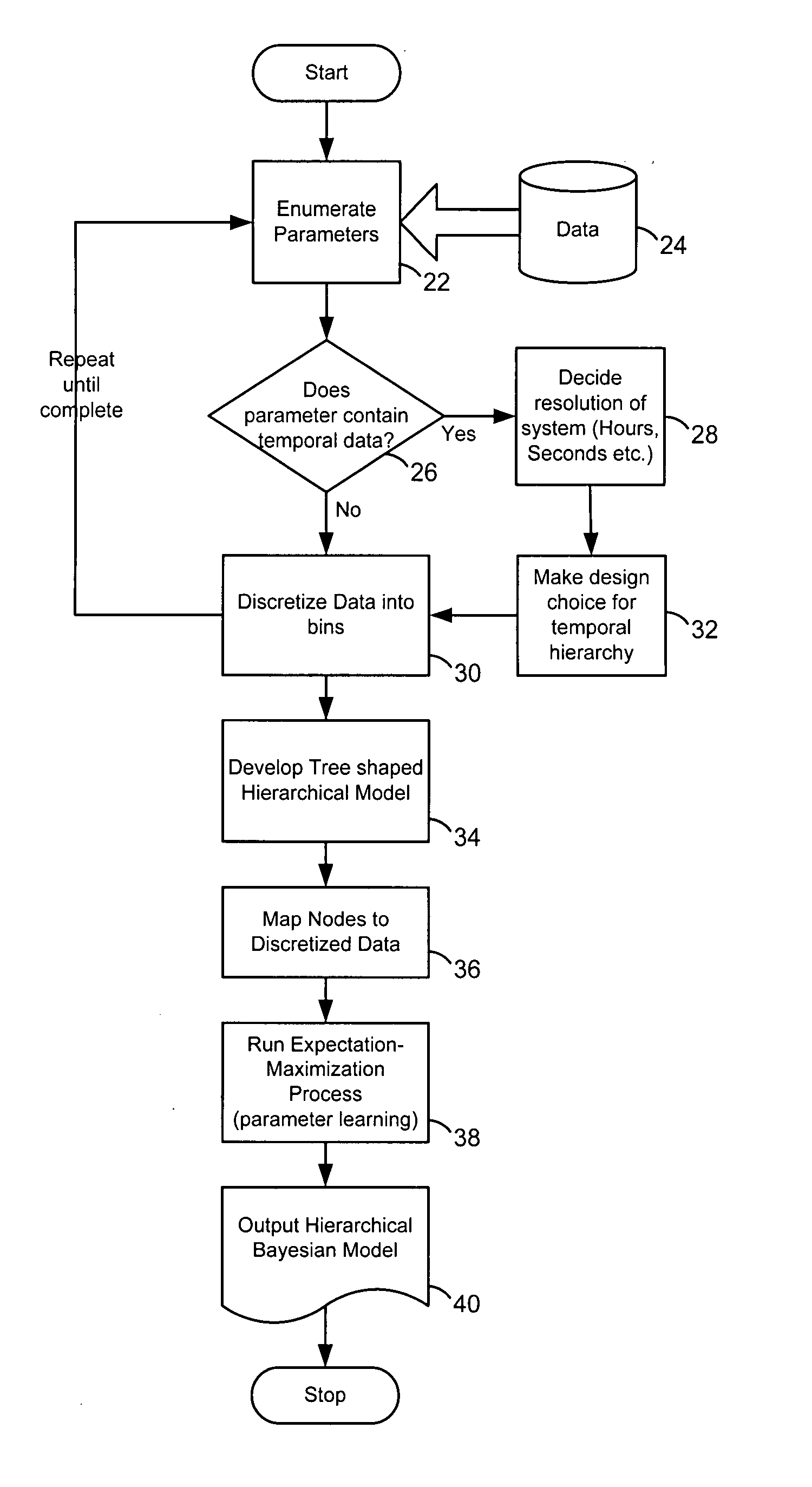

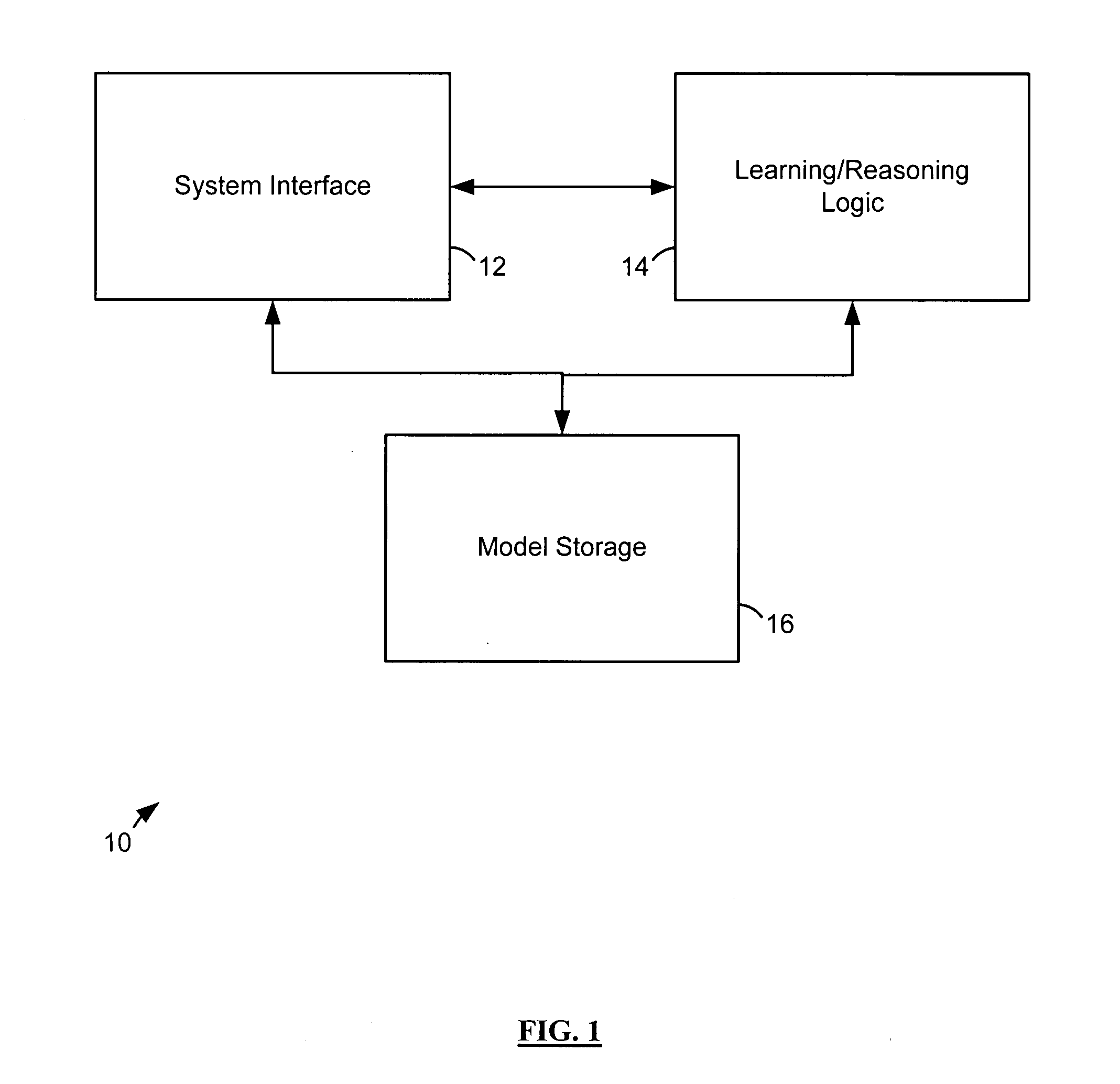

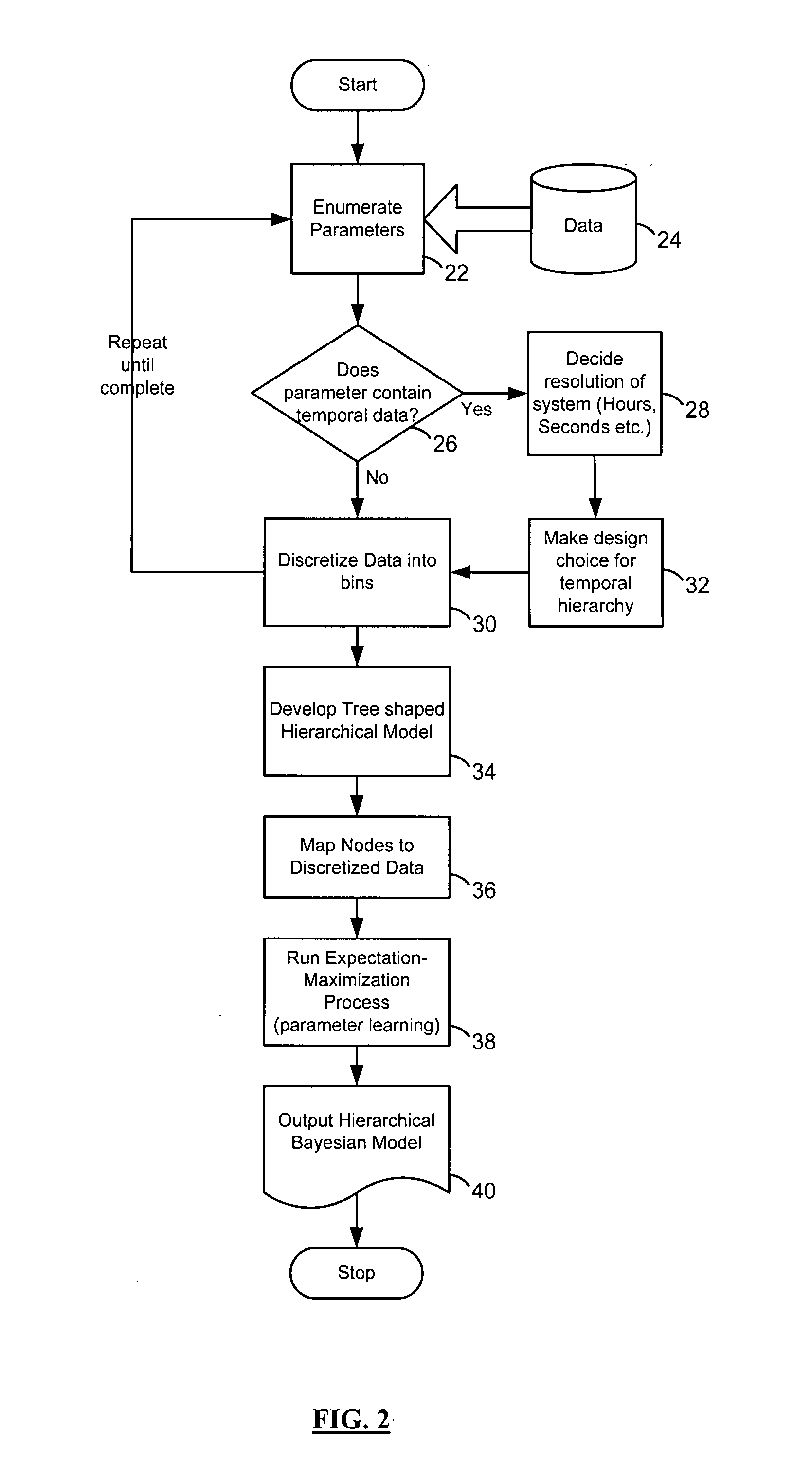

In one general aspect, a method of deriving information about behavior of a target system is disclosed. The method includes accessing one or more temporal variables for the target system, providing an identifier node at the top of a hierarchy of a tree-structured belief network, and assigning a different sub-tree in the network to each of the accessed temporal variables. The method also involves accessing evidence data, and deriving information about the behavior of the target system for the evidence data based on the tree-structured belief network.

Owner:COGNIKA INTELLIGENCE & DEFENSE SOLUTIONS

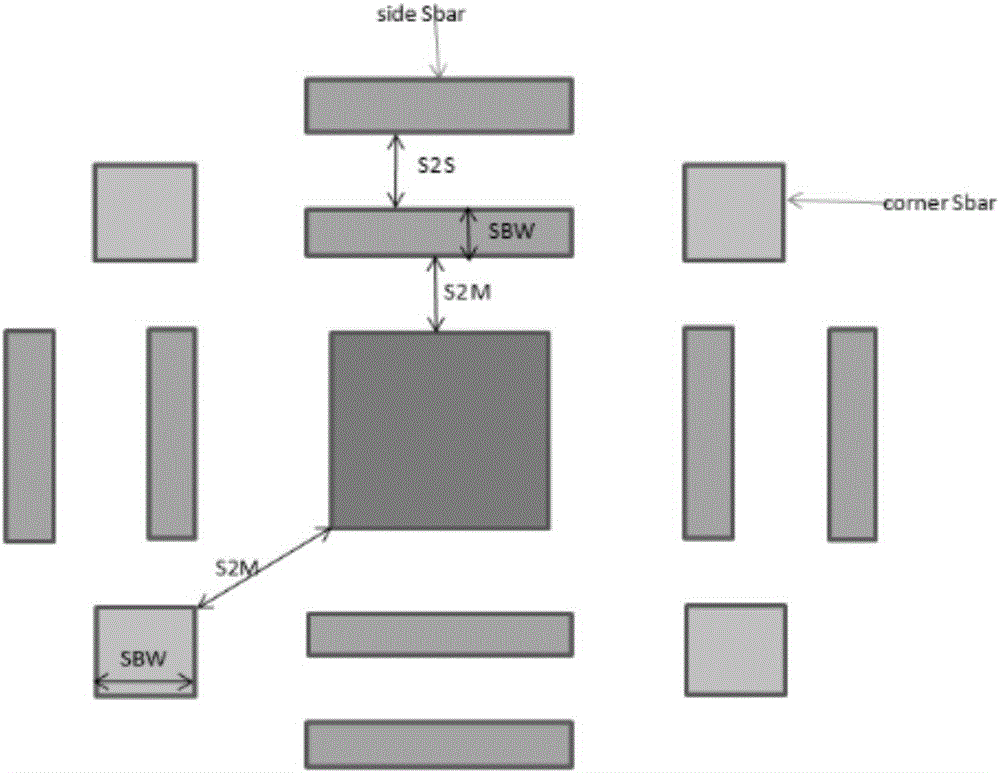

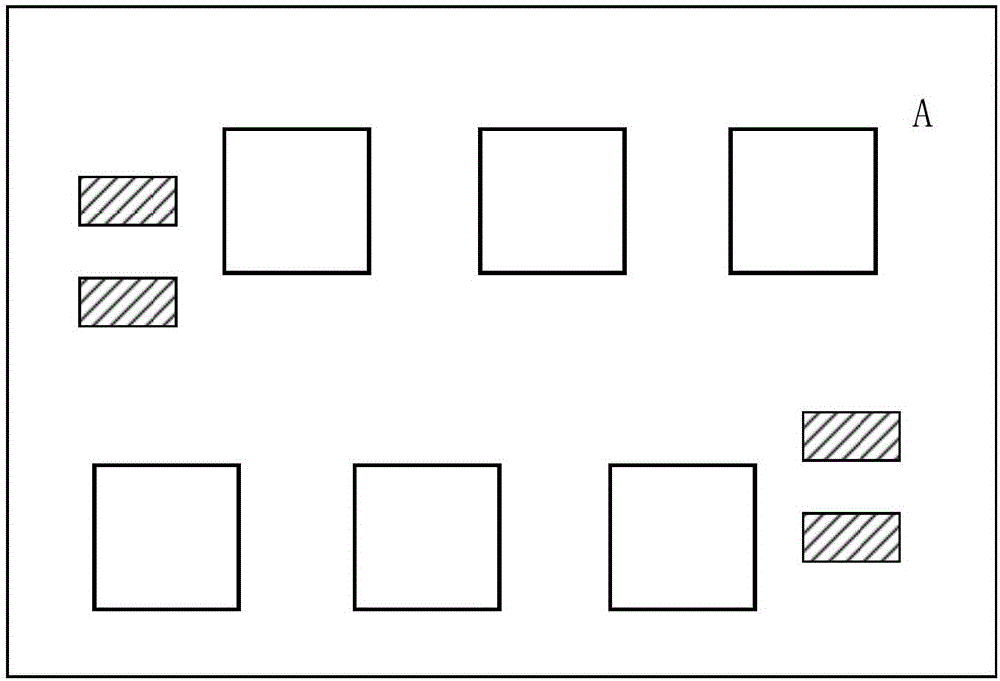

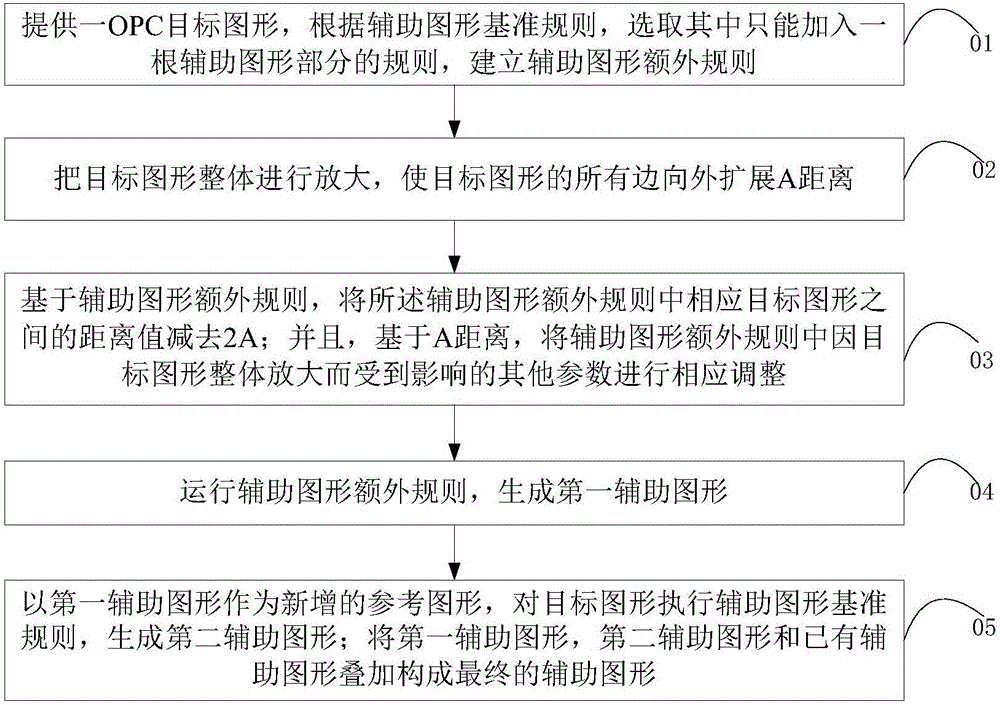

Method of adding auxiliary graph

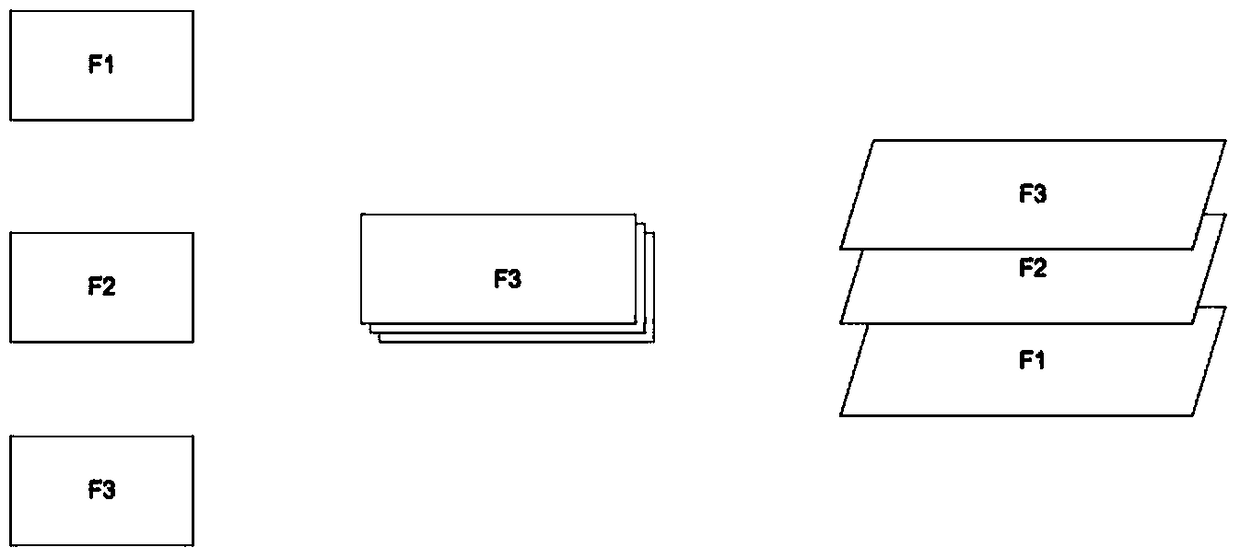

ActiveCN106527040AAdd reasonableSolve the problem of not being able to join AFPhotomechanical apparatusOriginals for photomechanical treatmentGraphicsAlgorithm

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Apparatus and method for learning and reasoning for systems with temporal and non-temporal variables

InactiveUS7792769B2Easy to learnAdd reasonableChaos modelsNon-linear system modelsReal variableGoal system

In one general aspect, a method of deriving information about behavior of a target system is disclosed. The method includes accessing one or more temporal variables for the target system, providing an identifier node at the top of a hierarchy of a tree-structured belief network, and assigning a different sub-tree in the network to each of the accessed temporal variables. The method also involves accessing evidence data, and deriving information about the behavior of the target system for the evidence data based on the tree-structured belief network.

Owner:COGNIKA INTELLIGENCE & DEFENSE SOLUTIONS

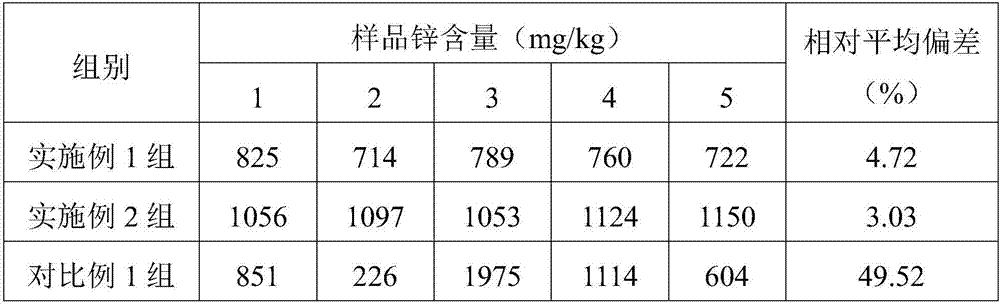

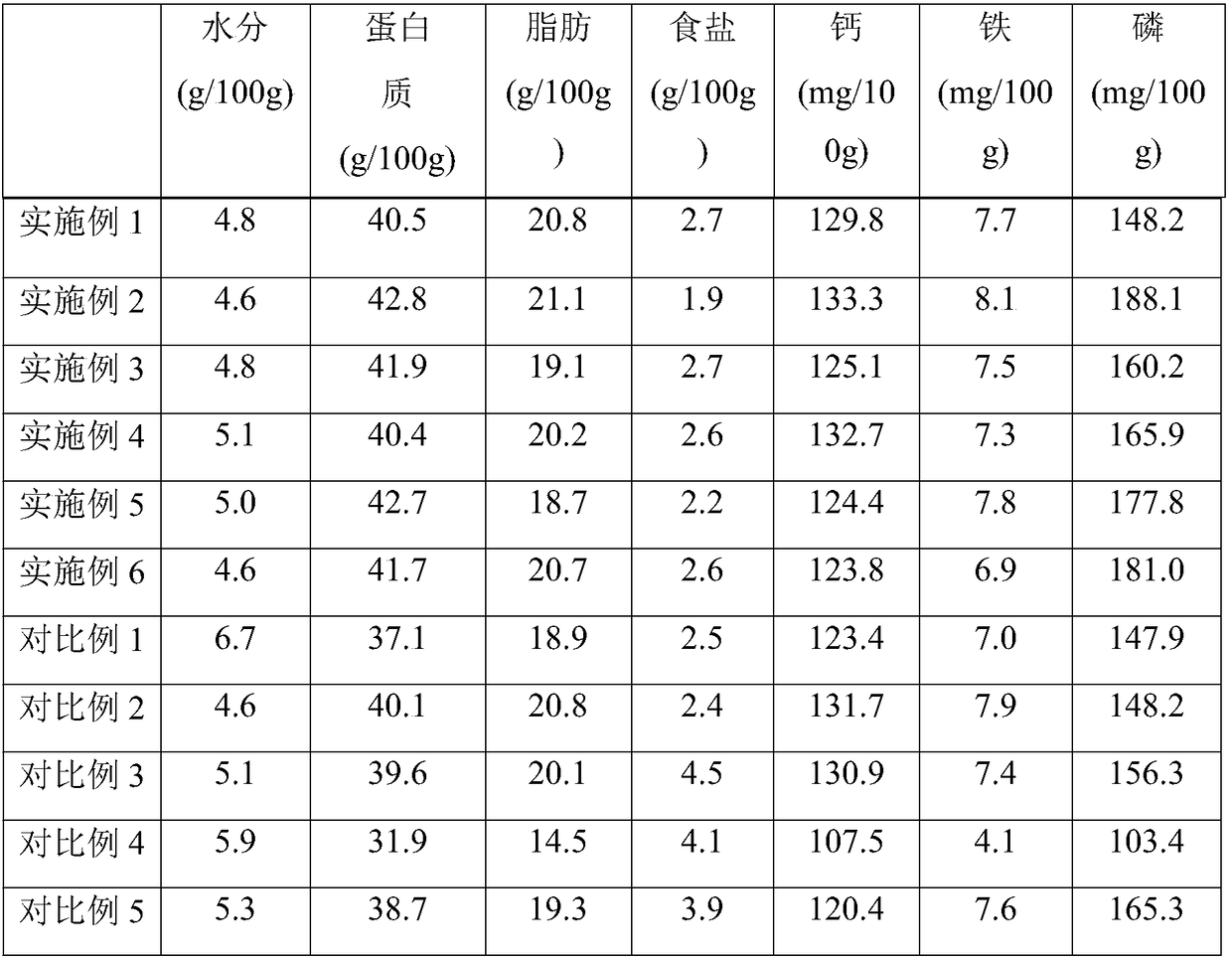

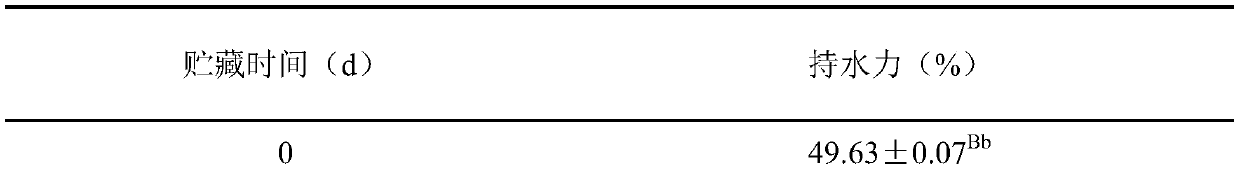

Beef paste and preparation method thereof

InactiveCN106942696AAdd reasonableReasonable supplementFood scienceDocosahexaenoic acidVegetable oil

The invention relates to the fields of foods and food processing, in particular to beef paste and a preparation method thereof. The beef paste is prepared from the following raw materials of beef, vegetable oil, isolated protein, starch, zinc gluconate, docosahexaenoic acid, a yeast extract, onion powder, olive oil, table salt, white granulated sugar, ginger powder, ground cinnamon, pricklyash peel powder, chili powder, garlic powder, pepper powder, gourmet powder, spices, phosphates, transglutaminase and D-isoascorbic acid, and is prepared through the technologies of treatment of the raw materials, injection, superfine comminution, mixing, decoction, and the like. Through the technology, zinc and the docosahexaenoic acid can be uniformly added to the beef paste, and through the edible amount of the beef paste, the total absorption amount of the zinc and the docosahexaenoic acid by human bodies can be accurately calculated and controlled; and finally, the purpose of reasonably complementing the zinc and the docosahexaenoic acid is realized.

Owner:山东如康清真食品有限公司

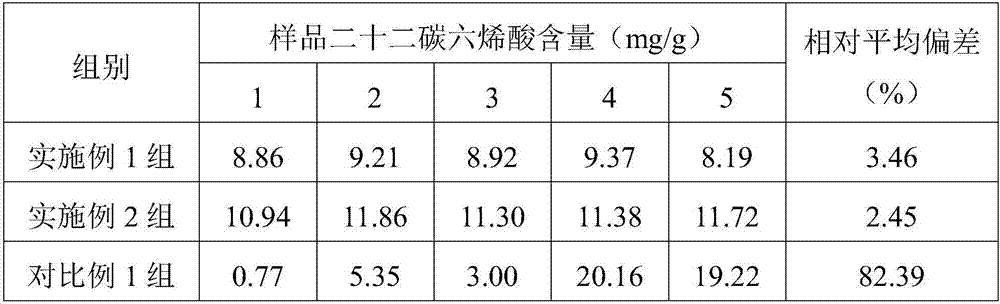

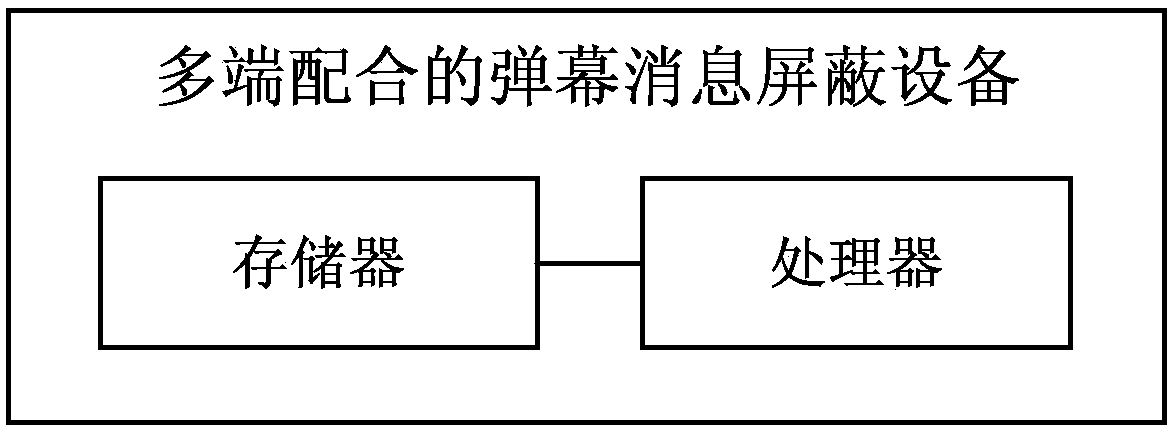

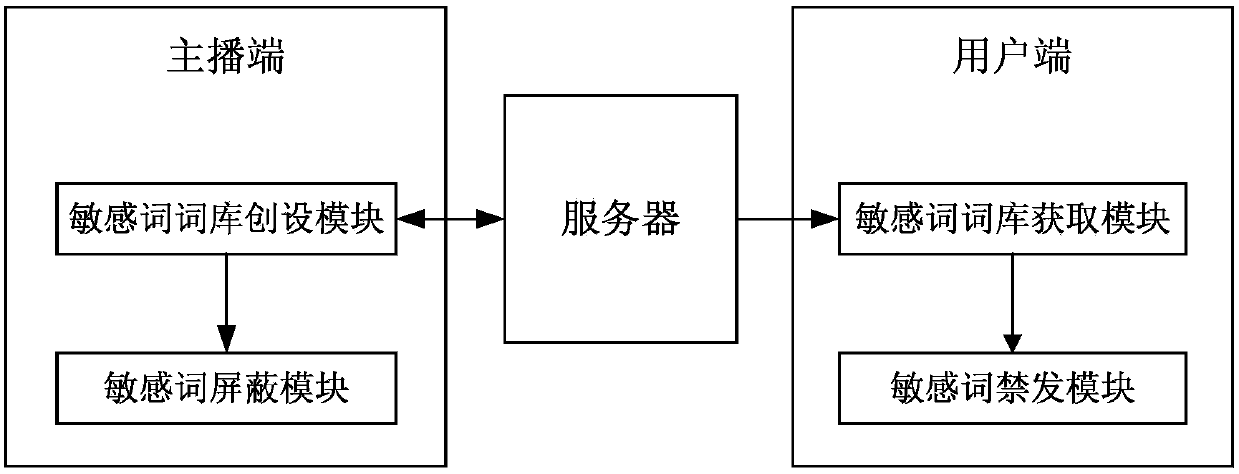

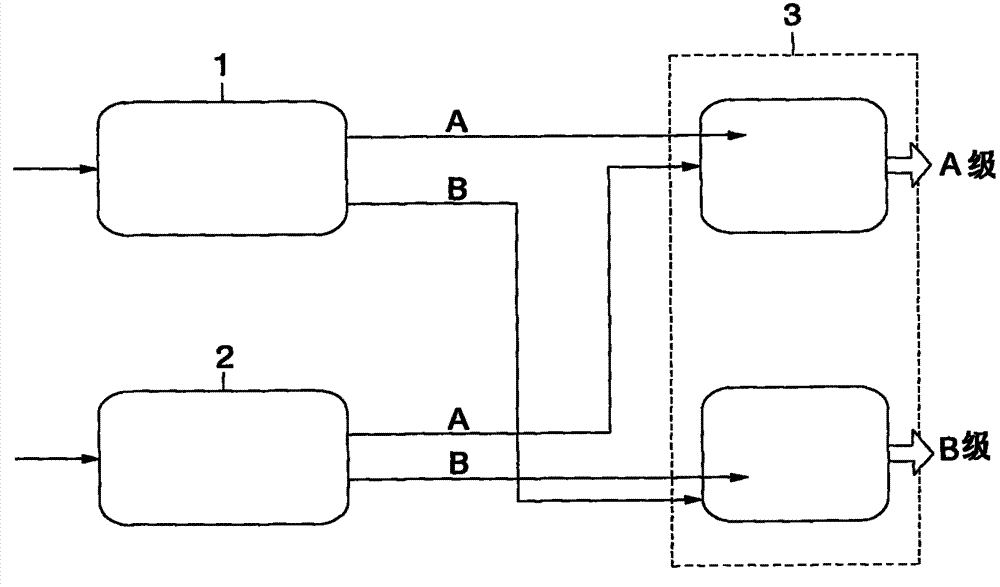

Multi-end cooperative bullet screen message blocking method, storage medium, equipment and system

InactiveCN109660869AImprove experienceRelieve pressureSelective content distributionQuality of serviceThe Internet

The invention discloses a multi-terminal cooperative bullet screen message blocking method, a storage medium, equipment and a system, and relates to the technical field of internet mobile terminal application development. The method comprises the steps that an anchor end sends sensitive words added by the anchor to a server for storage, and obtains a sensitive word library from the server for storage; a user end obtains a corresponding sensitive word library when the user enters a live broadcast room; when the user is about to send a bullet screen message, the bullet screen message is comparedwith the sensitive word library, and if the bullet screen message contains sensitive words, the user is forbidden from sending the bullet screen message; each time the anchor end receives one bulletscreen message, the bullet screen message is compared with a locally stored sensitive word library, and if the bullet screen message contains sensitive words, the bullet screen message can be blocked.According to the method and device, the blocking process of the sensitive word bullet screen messages can be transmitted to the user end and the anchor end for cooperative processing, so that the pressure of the server is greatly reduced, the service quality of the server is high, and the user experience is good.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

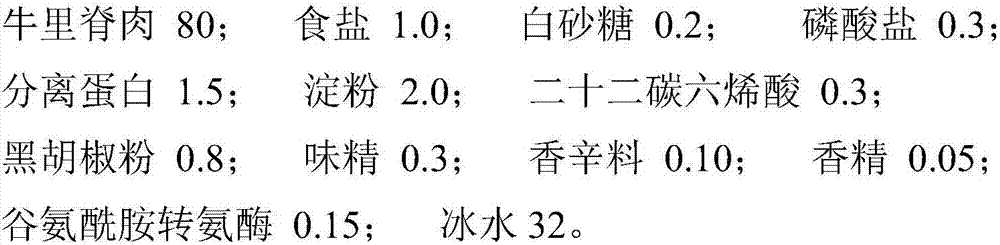

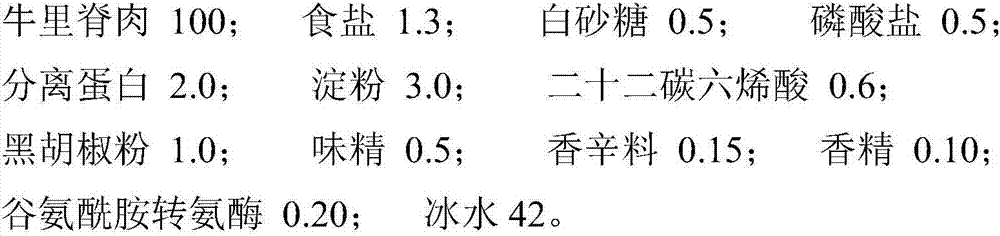

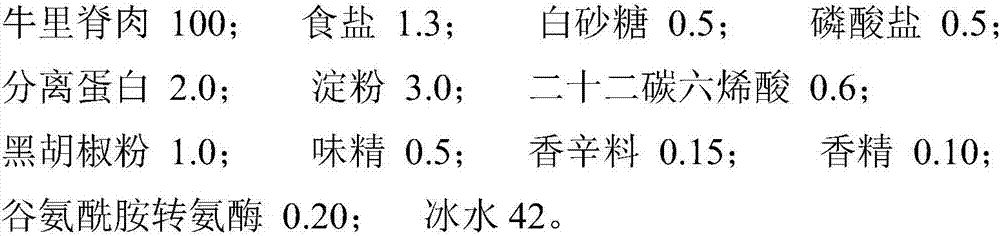

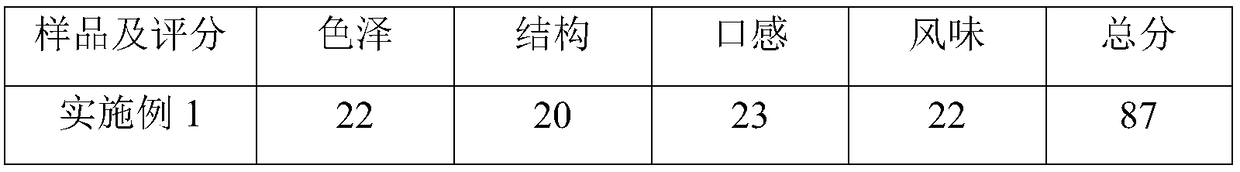

Children beefsteak capable of supplementing docosahexaenoic acid and preparation method of children beefsteak

The invention relates to the fields of food and food processing and particularly relates to a children beefsteak capable of supplementing docosahexaenoic acid and a preparation method of the children beefsteak. The children beefsteak capable of supplementing the docosahexaenoic acid, provided by the invention, is prepared from raw materials, i.e., beef short loin, common salt, white granulated sugar, phosphate, isolated protein, starch, docosahexaenoic acid, spices, black pepper powder, monosodium glutamate, flavoring essence, glutamine transaminage and ice water through the processes of unfreezing, segmentation, feed solution preparing, injection, twice rolling and kneading, encapsulation, standing, quick freezing and the like. An unsaturated fatty acid, i.e., docosahexaenoic acid can be uniformly added into the children beefsteak through the method provided by the invention, the total intake amount of the docosahexaenoic acid of children is accurately calculated and controlled by the beefsteak intake of the children, and finally, the aim of reasonably supplementing the docosahexaenoic acid is achieved.

Owner:中和澳亚(天津)实业有限公司

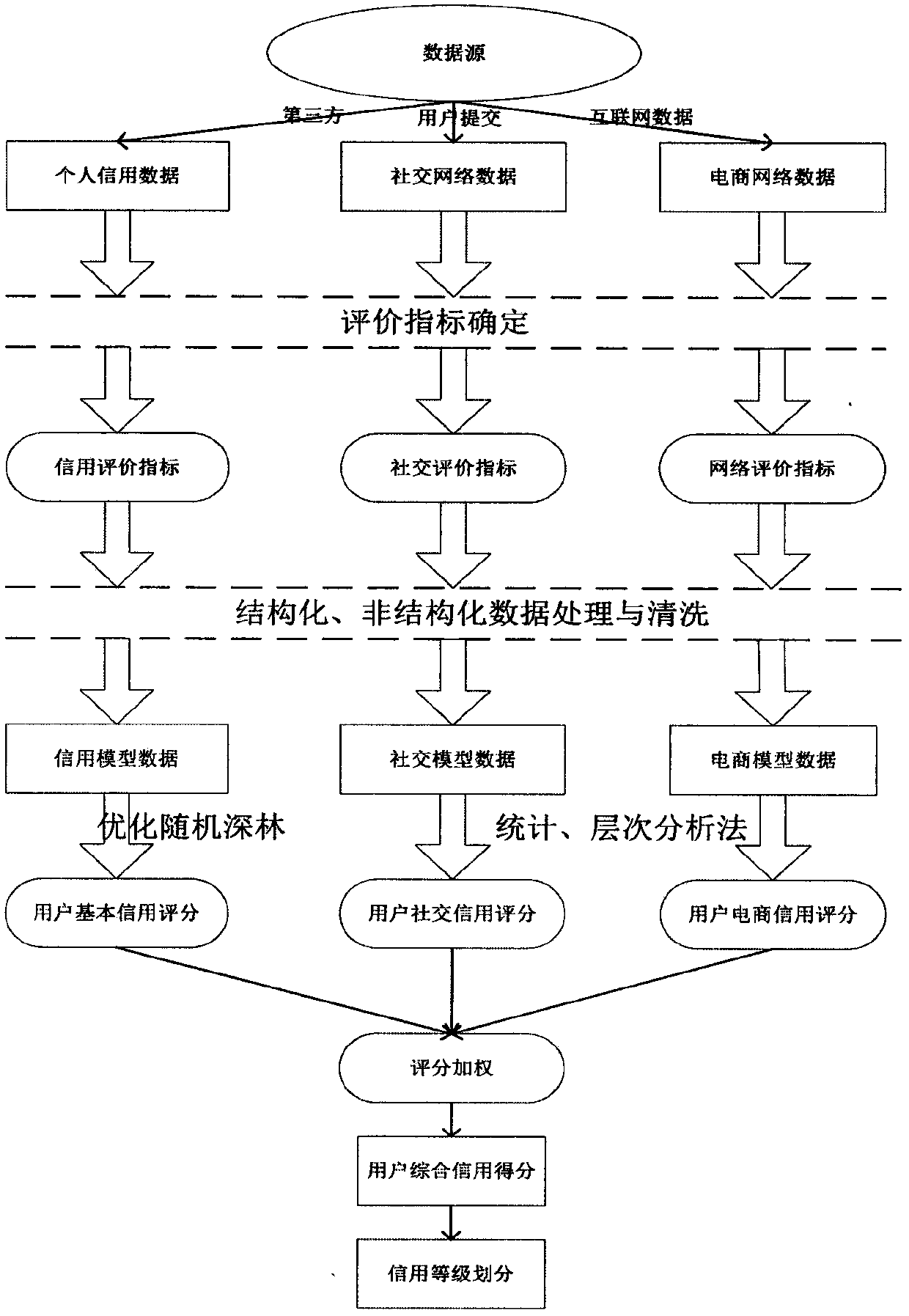

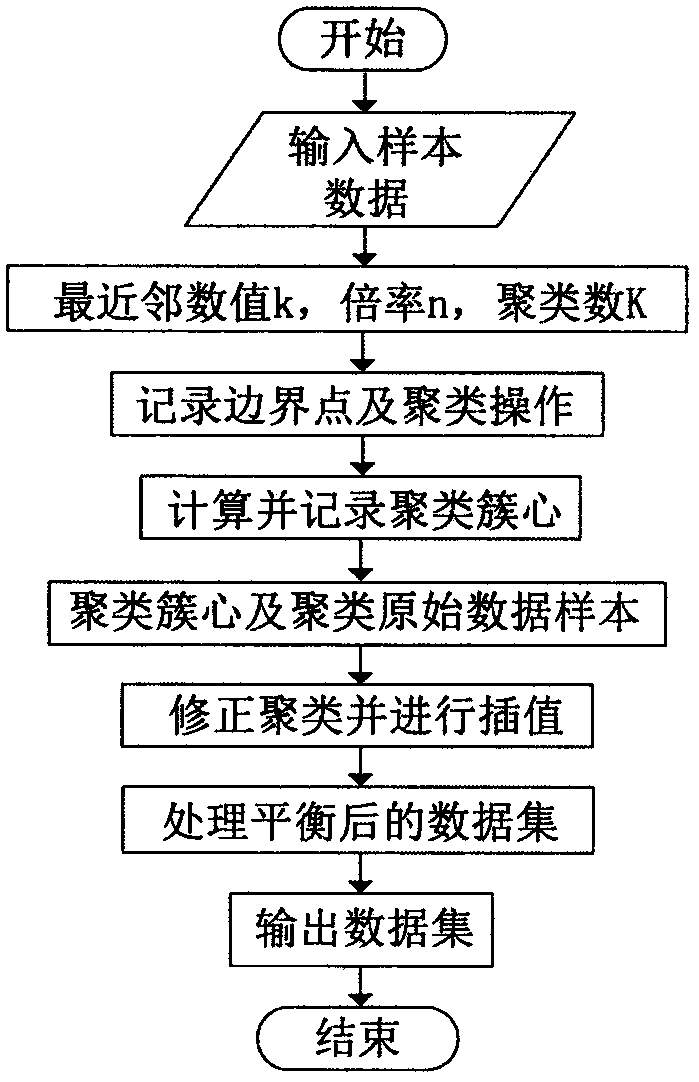

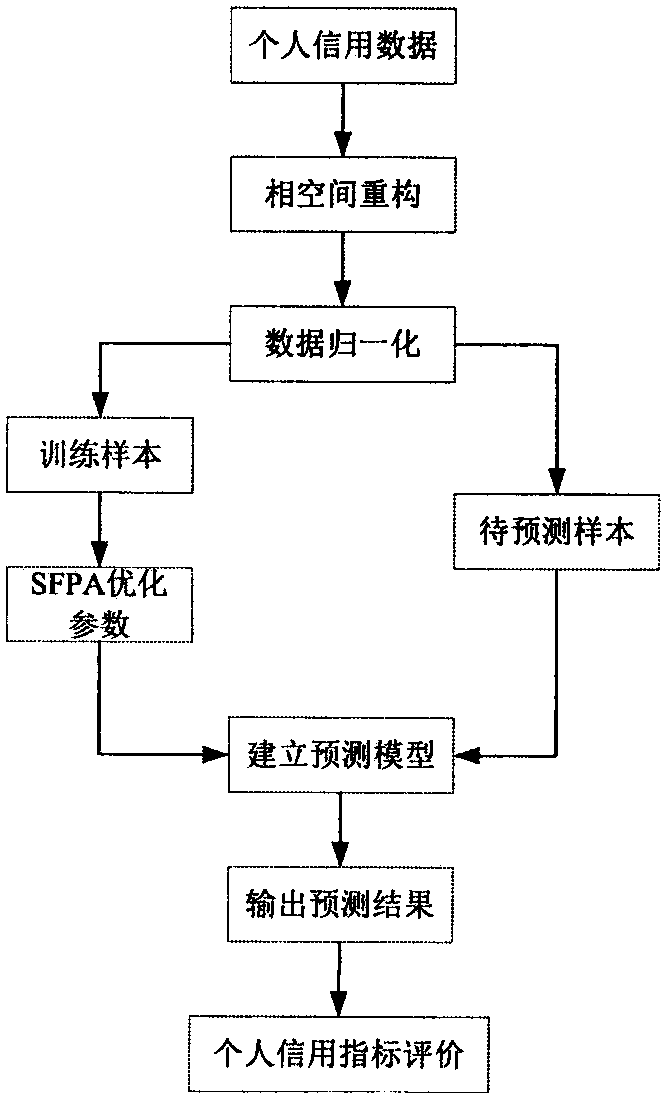

P2P personal-credit evaluation method and device based on data mining

InactiveCN108876595AEasy to operateAdd reasonableFinanceCharacter and pattern recognitionSupport vector machinePollination

The invention provides a P2P personal-credit evaluation method and device based on data mining. The method includes: S101, collecting data of a money borrower, wherein the data of the money borrower include personal-credit data, social-network data and e-commerce network data; S102, preprocessing the data of the money borrower in S101; S103, improving a flower pollination algorithm on the basis ofa simulated annealing algorithm, and optimizing parameters of support vector machines on the basis of improvement; S104, inputting the preprocessed personal-credit data to an optimized data trainingmodel to obtain a basic score of the money borrower; S105, using counting or an analytic hierarchy process to analyze the preprocessed social-network data and e-commerce network data to obtain two additional scores of the money borrower; and S106, determining a credit score of the money borrower on the basis of results obtained in S104 and S105. According to the technical solution provided by theinvention, the multi-faceted data can be fused for credit evaluation to improve accuracy of credit evaluation.

Owner:NANJING UNIV OF TECH

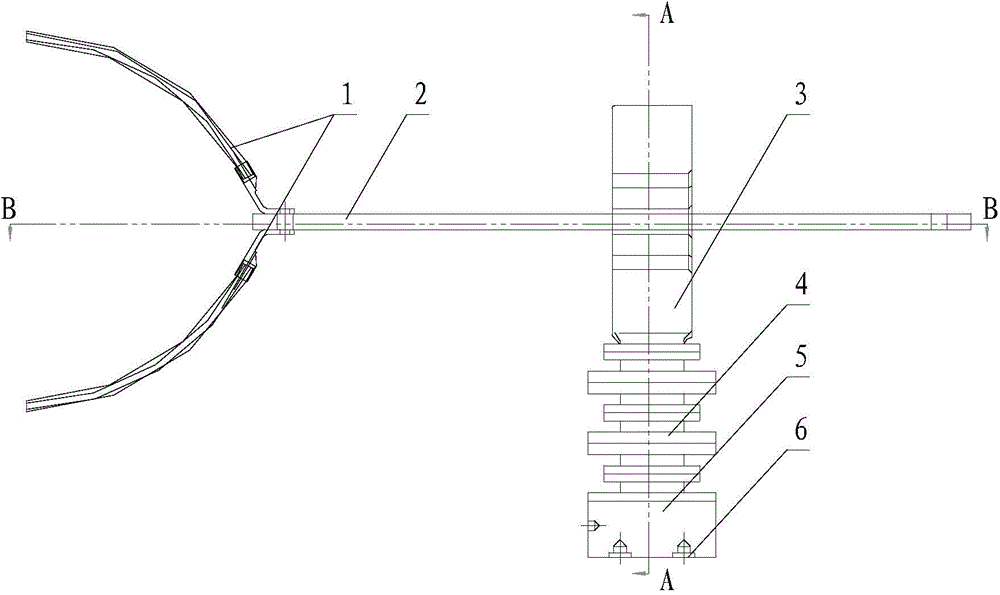

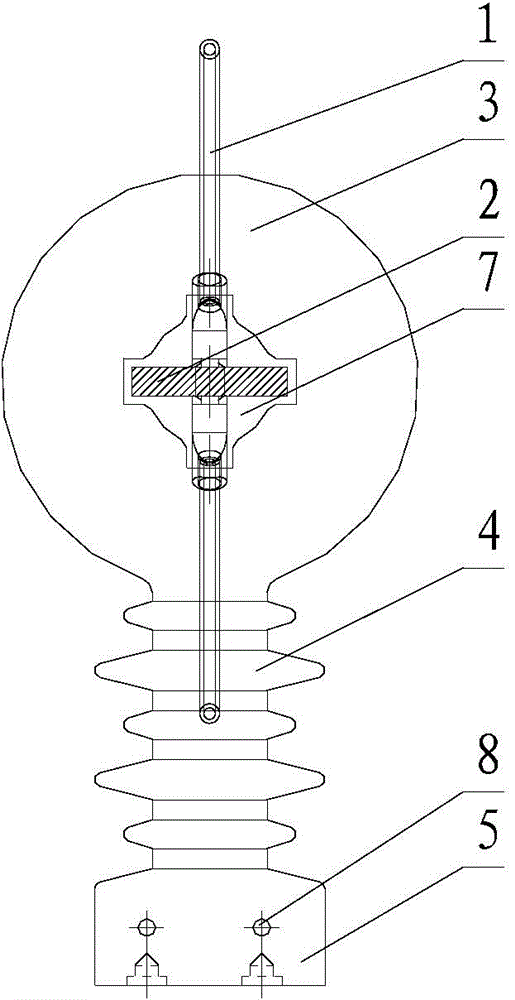

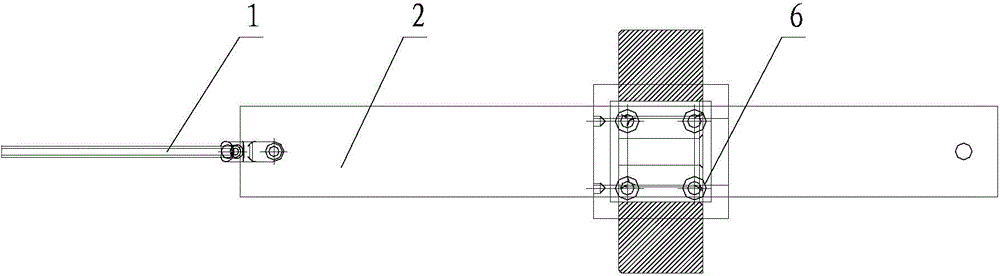

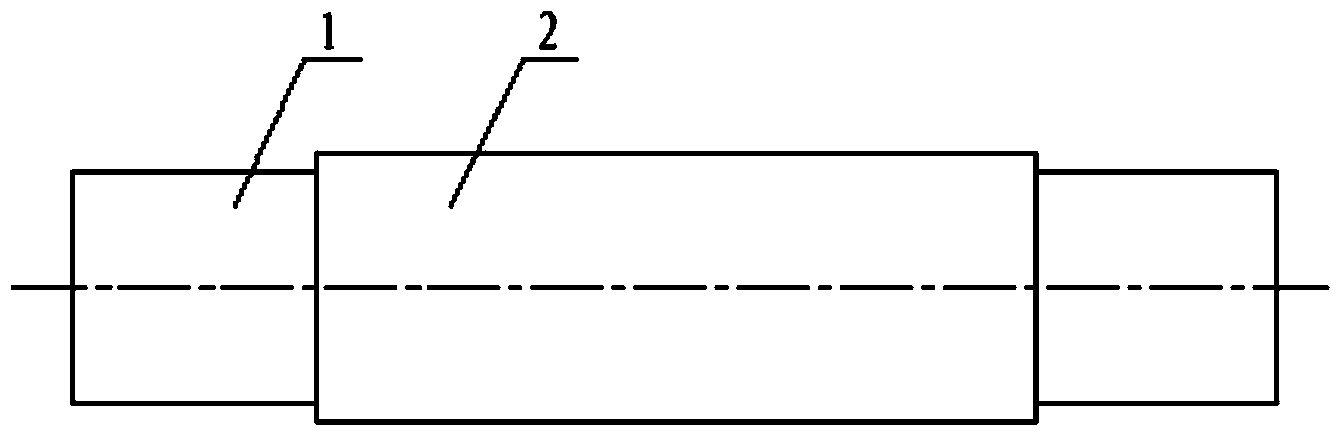

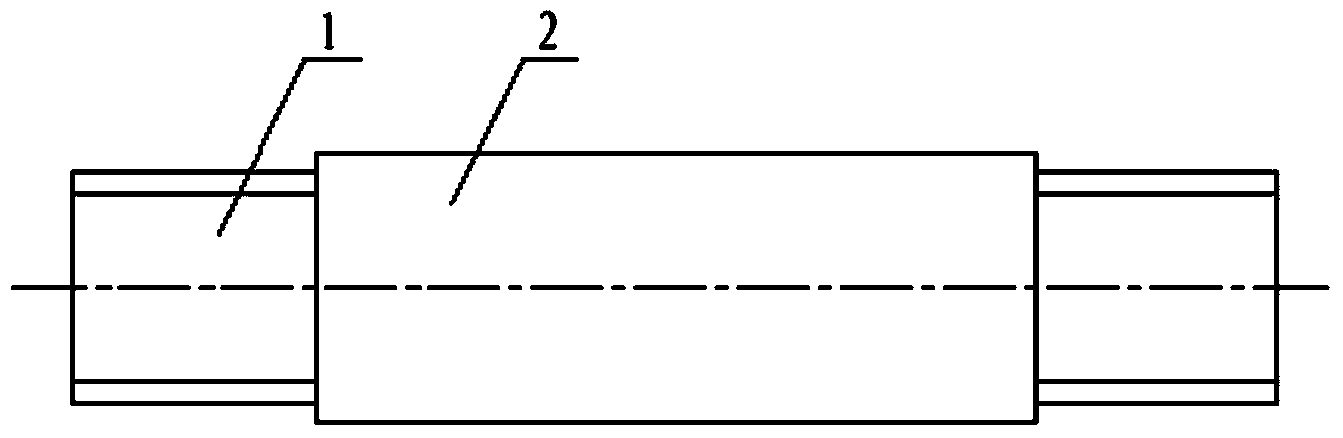

Inverted type current transformer

InactiveCN104064341AReduce economic costsHigh measurement accuracyTransformers/reacts mounting/support/suspensionTransformersCost (economic)Electricity

The invention relates to an inverted type current transformer. The current transformer comprises a transformer winding and a junction terminal, a bus hole for a copper bar or a single cable to pass through is formed in the axis of the transformer winding, the bus hole is in a shape of combination of a circle and a cross, the lower part of the transformer winding is mounted on a base through an insulated support, the base is provided with the junction terminal, and the transformer winding is electrically connected to the junction terminal through a conducting wire arranged in the insulated support. The inverted type current transformer provided by the invention is ingenious in design, novel in structure, reasonable in improvement and high in practicability, the transformer can be connected with a single cable, and can also be simultaneously connected with double cables, after the transformer is used, the economic cost can be greatly reduced, the measurement accuracy can be improved, the work efficiency can be improved, and the work safety can be ensured.

Owner:STATE GRID CORP OF CHINA +1

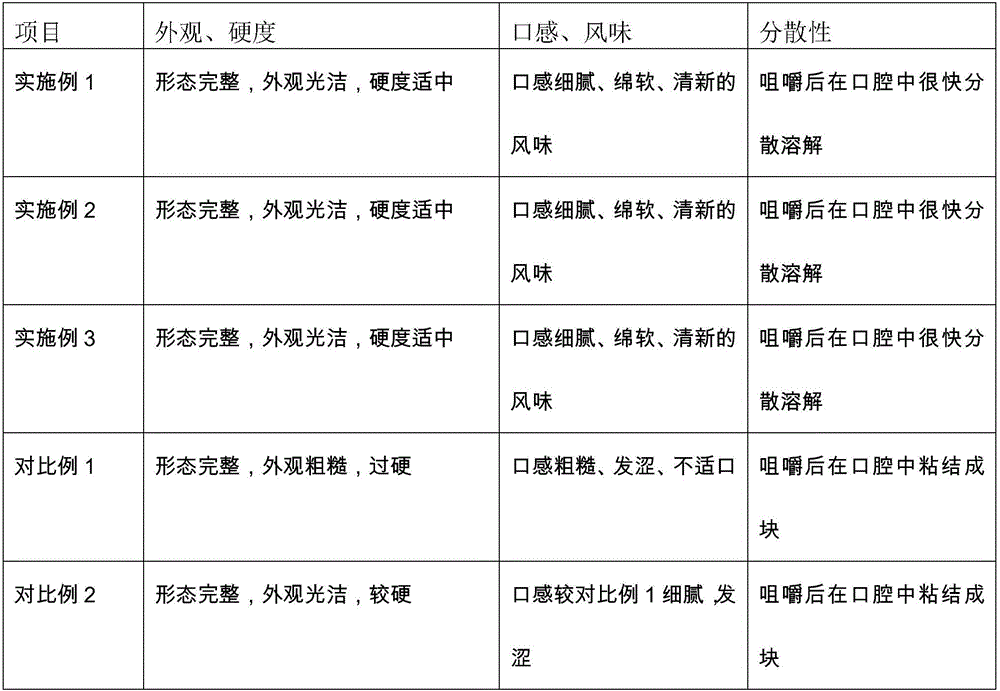

Maize germ chewable tablet and preparation method thereof

InactiveCN106360670ANutritional diversityEasy to eatSugar food ingredientsFood ingredient functionsImpurityMaltodextrin

The invention relates to a maize germ chewable tablet and a preparation method thereof. The preparation method includes the steps of: removing impurities, performing enzyme deactivation, crushing the maize germ and mixing the maize germ with crystalline glucose, crystalline xylose, maltodextrin, corn starch and the like auxiliary materials to perform granulation, and tabletting the granules into the maize germ chewable tablet. With the maize germ as a raw material, endogenous nutrients in the endogenous are utilized. The maize germ flour, the crystalline glucose and the crystalline xylose are compounded to solve the defects that the maize germ product is astringent, is poor in rehydration and dispersion properties and is monotonic in taste. The maize germ chewable tablet is an instant food containing abundant nutrients and being green and safe.

Owner:SHANDONG LUZHOU FOOD GROUP

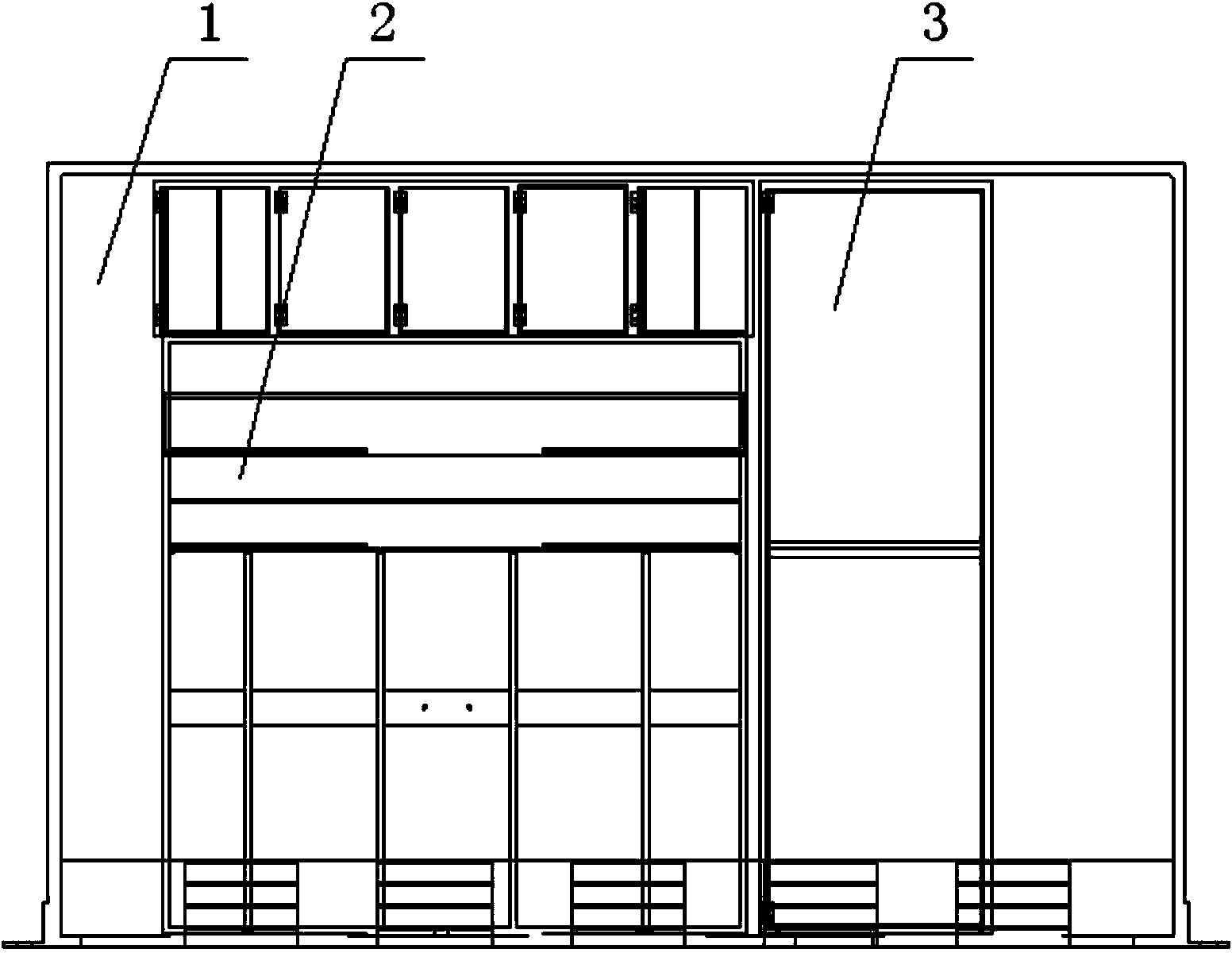

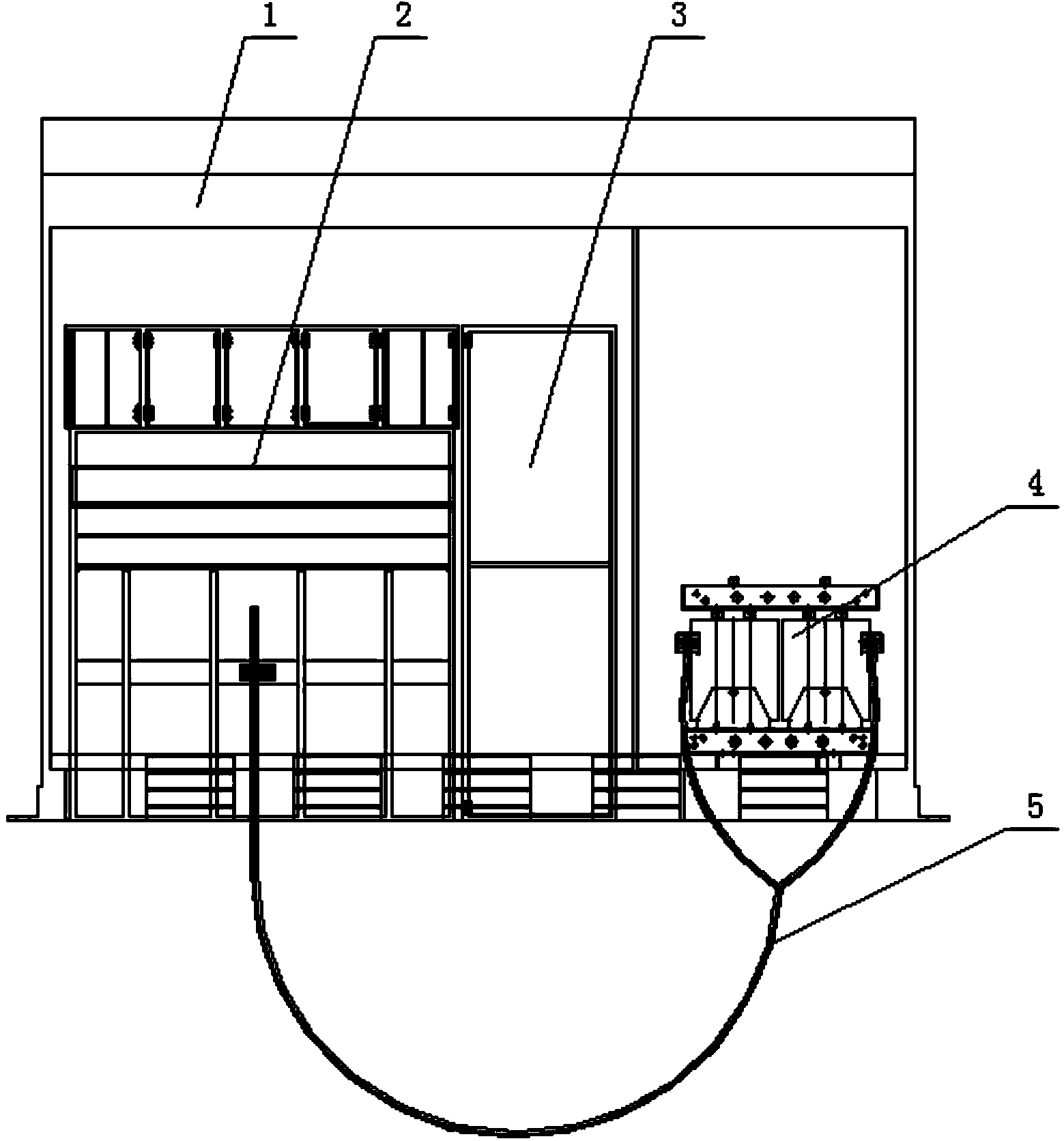

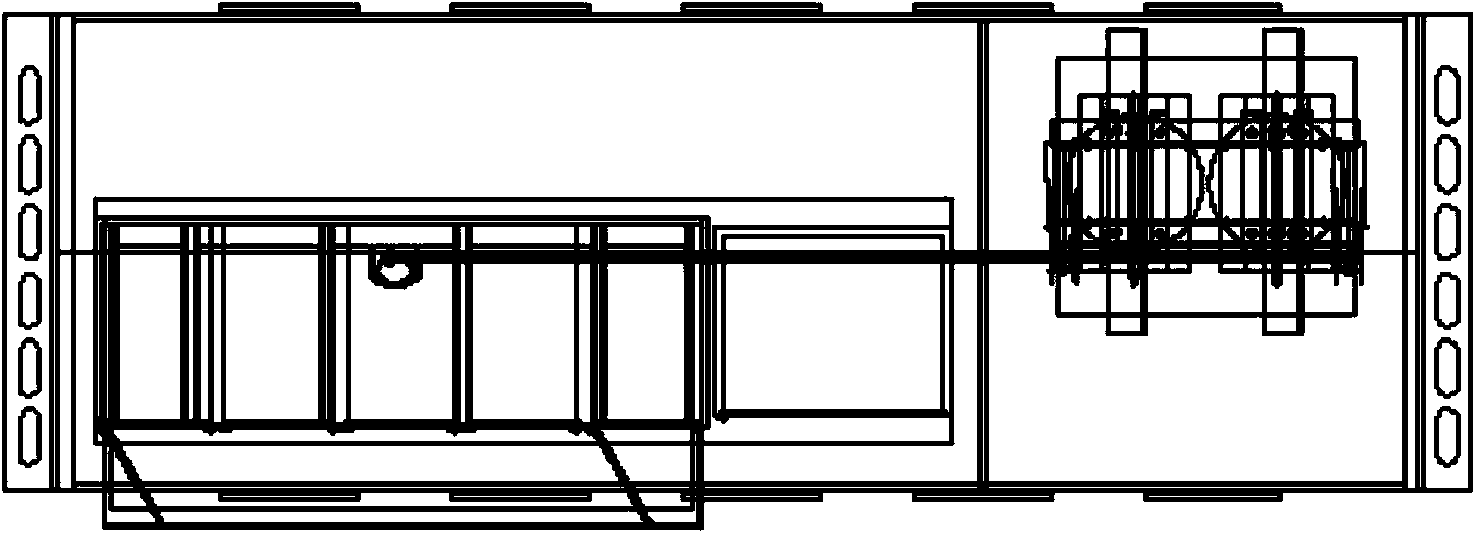

Box-type opening and closing station without external power supply

InactiveCN104167673ARealize power supplyLow costSubstation/switching arrangement detailsElectricityTransformer

The invention relates to a box-type opening and closing station without an external power supply. The opening and closing station includes a casing, a ring main unit and a power supply communication screen. The ring main unit and the power supply communication screen are installed in a casing. The ring main unit is electrically connected with the power supply communication screen. A station dry-type transformer is installed in the casing. The ring main unit is connected with a high-voltage side of the station dry-type transformer through a cable. A low-voltage side of the station dry-type transformer is connected with the power supply communication screen. The opening and closing station is a box-type opening and closing station which is ingenious in design, reasonable in improvement, easy to realize and free from an external power supply so that use of the box-type opening and closing station is capable of simplifying work procedure, reducing workload, speeding up construction progress and reducing construction cost.

Owner:天津三源电力智能科技有限公司

Low-salt preserved fishes and preparation method thereof

InactiveCN109452577AReduce salt contentShorten drying timeFood thermal treatmentMeat/fish preservation by heatingCooking & bakingFreeze-drying

The invention discloses low-salt preserved fishes and a preparation method thereof. Fresh live fishes are selected, pretreated, pickled with pickling materials, then subjected to thermal processing, subjected to baking or freeze drying, and subjected to packaging and sterilization so as to obtain the low-salt preserved fishes with the salt content of 3% or below. According to the invention, the preserved fishes obtained by pickling with the self-made pickling materials not only can restore the fresh and tender meat quality of fresh fishes, but also retain various nutrient components in the fresh fishes, wherein the content of vitamin A is particularly high, and the contents of elements such as phosphorus, calcium and iron are very high. The preserved fishes prepared by the method have theadvantages of low salt content, uniform color, sanitation, health, convenience for eating and traditional smoking flavor, are a healthy fish product, and have good market prospect and market popularization value.

Owner:湖南唐人神肉制品有限公司

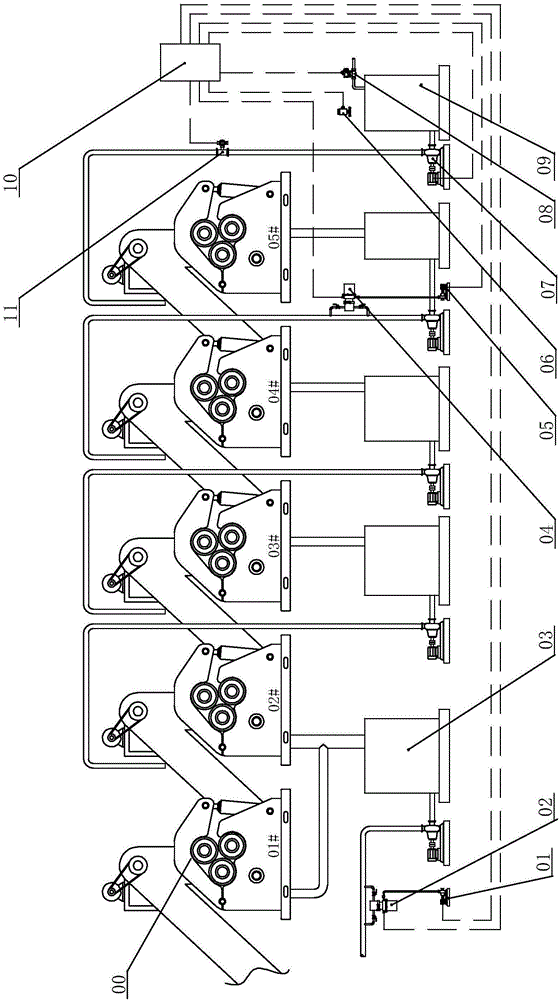

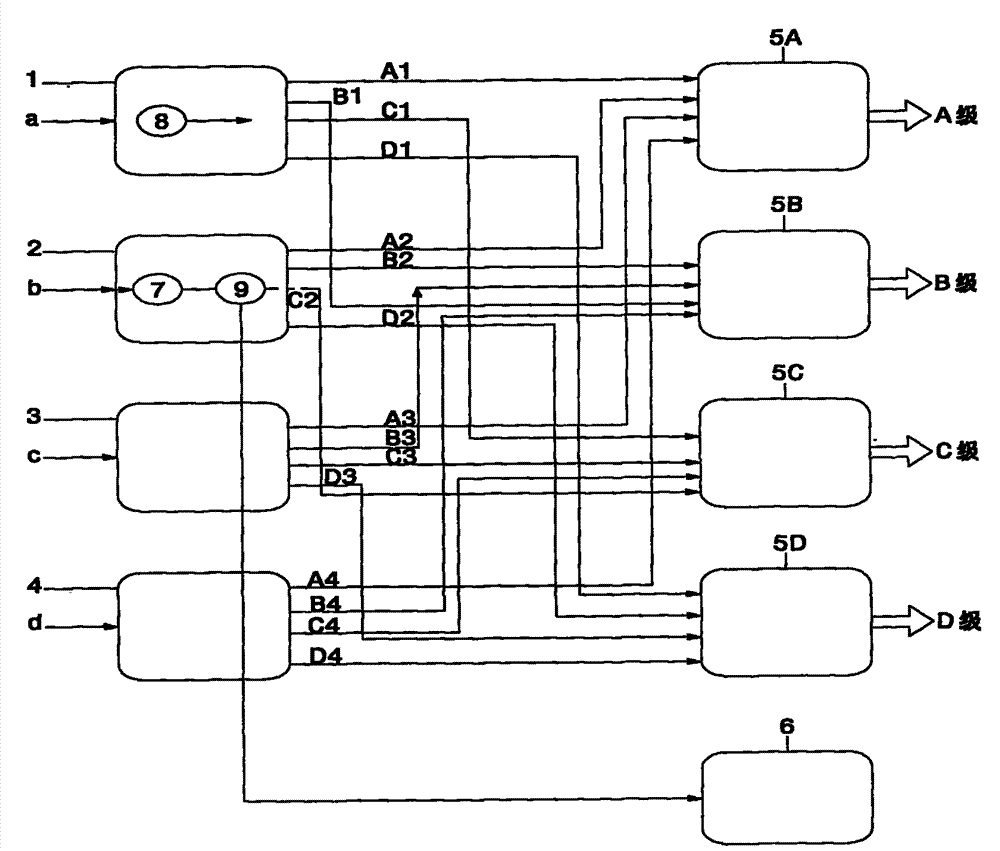

Online automatic control system and control method for permeation water of sugarcane pressing machine

ActiveCN106515081AAdd reasonableThe amount added is reasonablePressesAutomatic controlControl system

The invention discloses an online automatic control system and control method for permeation water of a sugarcane pressing machine. According to the system, a first sugarcane juice concentration detector is installed on an outlet of a number 1& 2 sugarcane juice box; a last sugarcane juice concentration detector is installed at the position of an outlet of a last sugarcane juice box; a permeation water hot water pipeline of a last pressing machine is provided with a hot water flow meter; and the first sugarcane juice concentration detector, the last sugarcane juice concentration detector, a hot water pump and the hot water flow meter are all connected with a control host. A hot water tank liquid level meter of a hot water tank and a self-holding electromagnetic valve at a connected-in hot water pipeline are also connected with the control host. According to the control method, a sugarcane juice concentration value of the control host is compared with a set value, and the rotating speed of the hot water pump is adjusted; and the control host reckons whether the current permeation water adding amount meets the requirement or not according to the hot water flow and a last sugarcane juice concentration value, accordingly the hot water pump is controlled, and the permeation water adding amount is adjusted. The control host controls the self-holding electromagnetic valve to perform automatic hot water adding according to a signal of the hot water tank liquid level meter. The online automatic control system and control method for the permeation water of the sugarcane pressing machine perform automatic detection and real-time control on reasonable adding of the permeation water, and energy conservation and emission reduction are achieved.

Owner:钦州华成自控设备有限公司

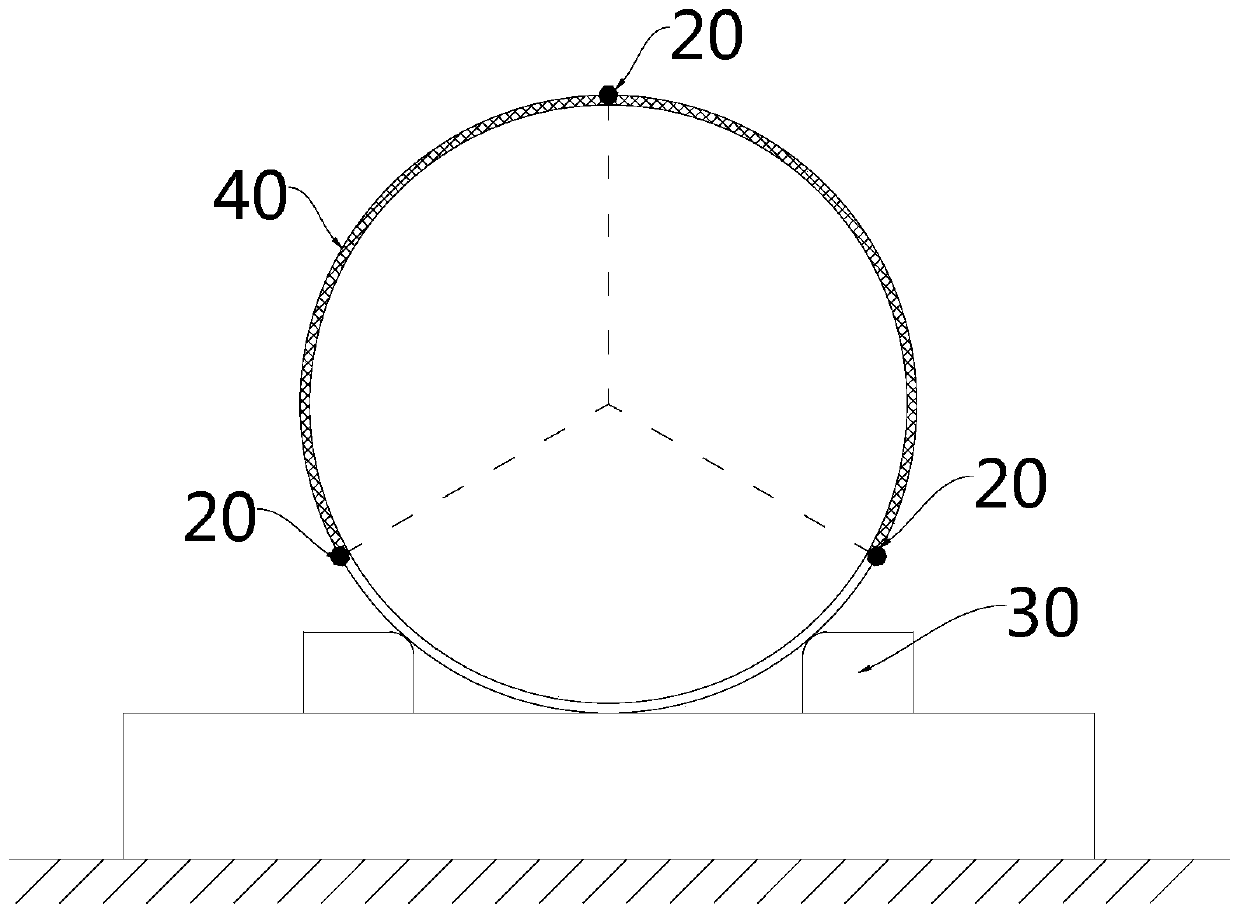

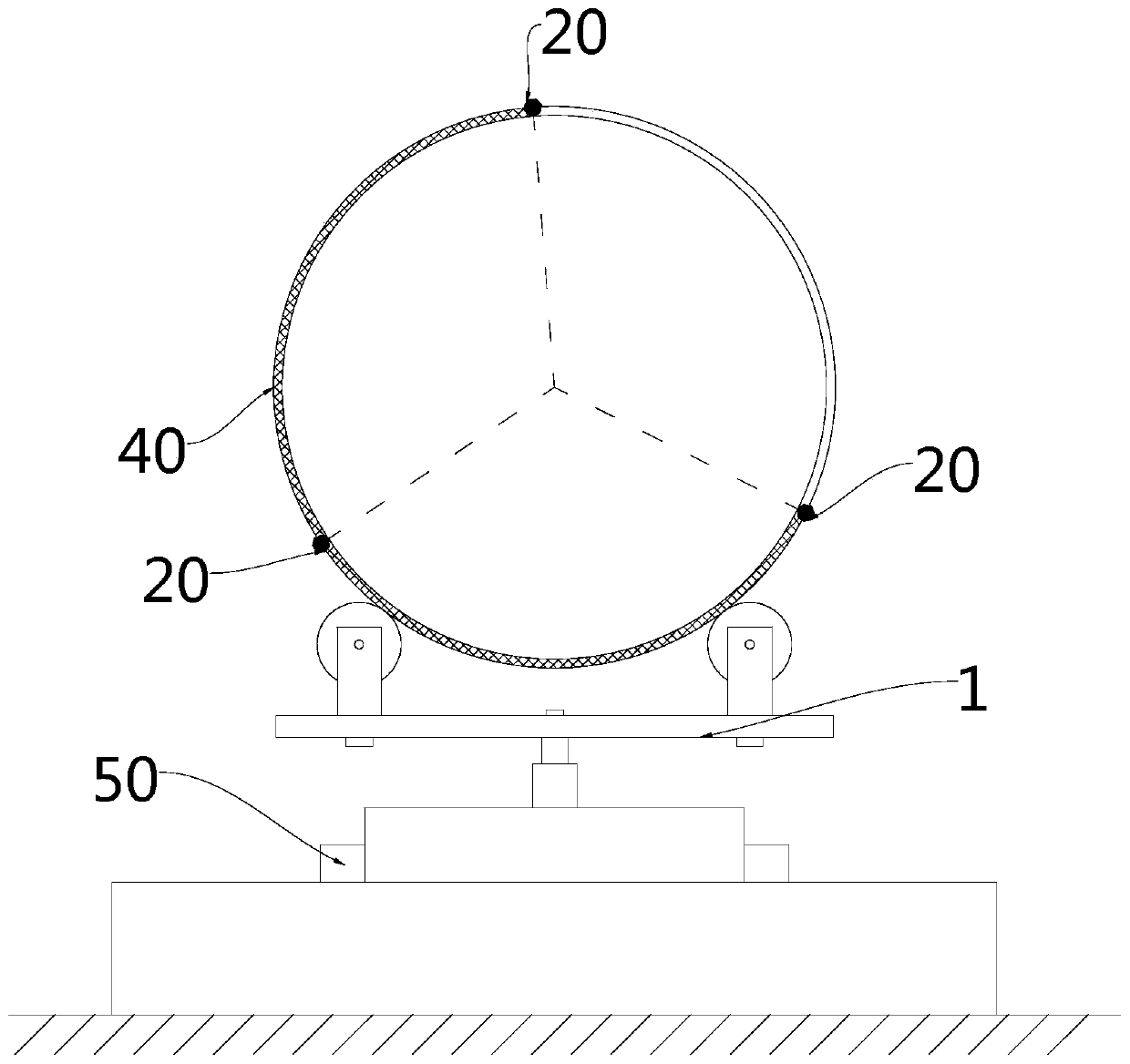

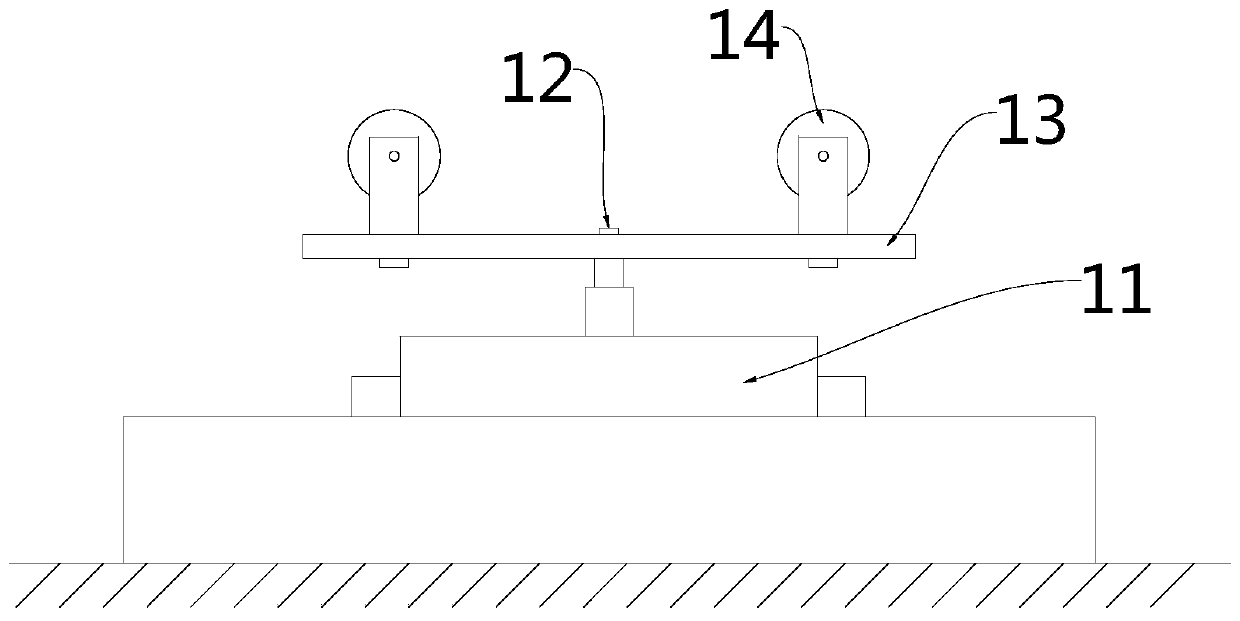

Welding process for equal-diameter large quartz pipes

The invention discloses a welding process for equal-diameter large quartz pipes. The welding process for the equal-diameter large quartz pipes comprises the following steps of A. carrying out chamfering; B. carrying out cleaning and drying; C. placing the two large quartz pipes on a marble platform, and reserving a gap with a size of 1mm; D. welding three welding points which are uniformly distributed along the circumference; E. taking two sections of an arc-shaped welding flux, and fusing the arc-shaped welding flux to complete welding for 2 / 3 of the circumferences of the large quartz pipes; F. carrying out lifting, placing a plurality of graphite rolling wheel assemblies under the large quartz pipes, and rotating the large quartz pipes by 90-180 degrees; G. adding the arc-shaped welding flux to the gap of the unwelded 1 / 3 of the circumferences, and fusing the arc-shaped welding flux to complete welding for the remainder 1 / 3 of the circumferences; and meanwhile, carrying out filler supplementing on the welded 2 / 3 of the circumferences; H. carrying out filler supplementing on the remainder 1 / 3 of the circumferences; and I. carrying out finished product inspection. The welding process for the equal-diameter large quartz pipes has the advantages of being capable of ensuring the concentricity of the two large quartz pipes well, reasonable in welding flux distribution and addition, capable of carrying out rapid welding on the whole circumferences of the large quartz pipes, good in welding effect, and high in welding yield.

Owner:HUZHOU DONGKE ELECTRONICS QUARTZ

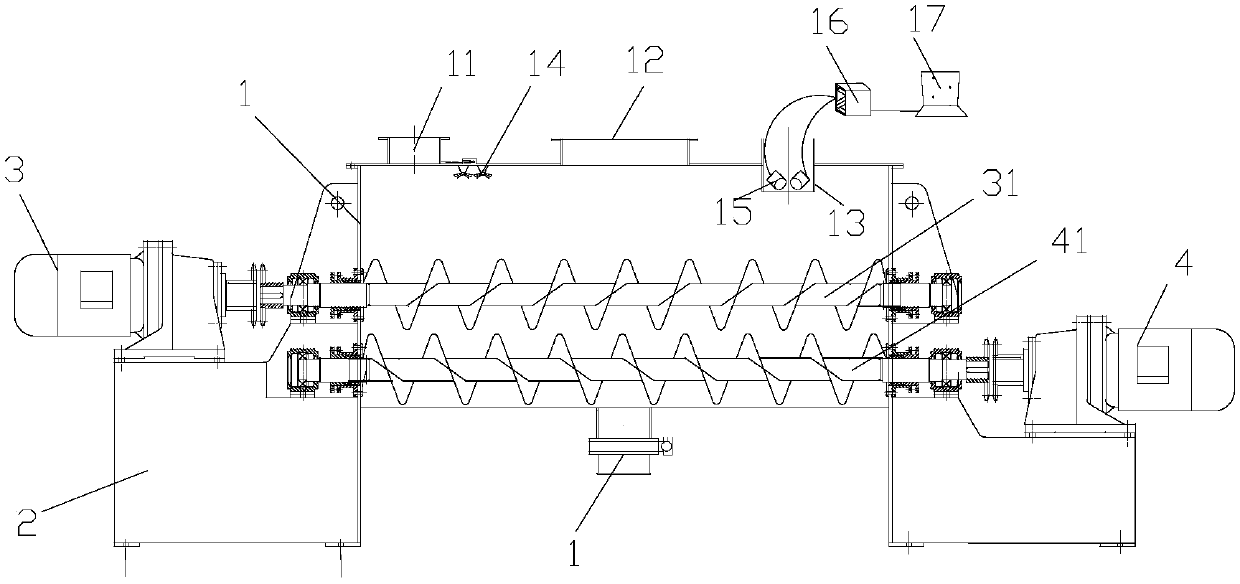

Stirring equipment capable of realizing online near infrared spectrum monitoring of soil stabilizing process

InactiveCN109569358AEconomic benefit maximizationAvoid collisionTransportation and packagingRotary stirring mixersPeak valueEngineering

Stirring equipment capable of realizing online near infrared spectrum monitoring of soil stabilizing process comprises a stirring device and a near infrared detection system. The stirring device comprises a stirring box, the top of the stirring box is provided with a soil feeding port, an agent feeding port and a monitoring port, a first spiral stirrer and a second spiral stirrer are arranged in the stirring box, the near infrared detection system comprises a near infrared detector, a cover made of quartz, an agent nozzle and a processor, the bottom of the monitoring port is closed through thecover, the cover protrudes into the stirring box, and at least one near infrared detection probe connected with the near infrared detector and facing soil in the stirring box are arranged in the cover. H-O peak value change in the soil is detected in real time through the probes to judge solid-liquid ratio of soil to water in the soil so as to judge stirring uniformity of the soil and a solidifying and stabilizing agent, so that reasonable agent adding is ensured, and economic maximization is realized.

Owner:长沙工研院环保有限公司

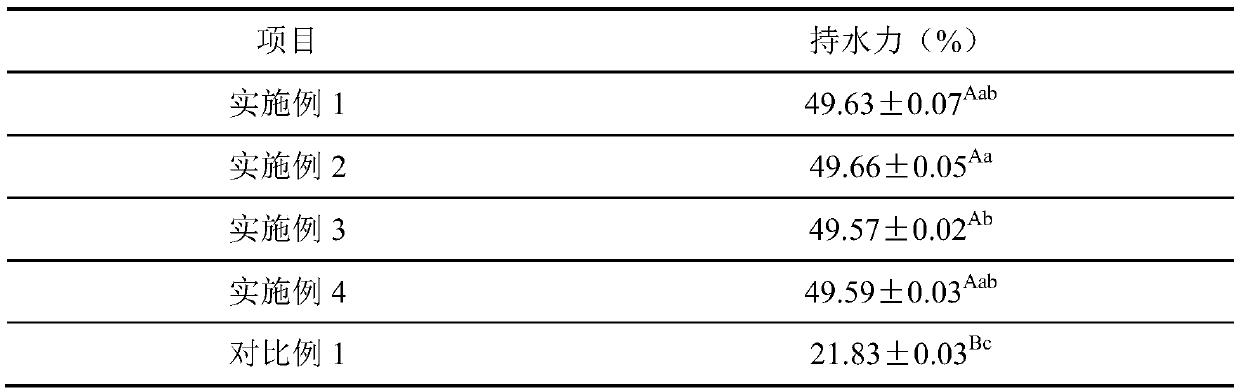

DHA-containing peanut yoghurt and preparation method thereof

InactiveCN110140771AAdd reasonableSolve the shortcomings of easy oxidation and deteriorationMilk preparationWater bathsGelatin

The present invention discloses DHA-containing peanut yoghurt and a preparation method thereof. The preparation method comprises the following steps: peanut protein liquid preparation, blending, homogenization, sterilization, cooling, fermentation and finished product preparation. The preparation method selects DHA micro-capsules to replace DHA algae oil, the DHA micro-capsules are added into theyoghurt, and the addition method is optimized, so that the addition process of DHA is more reasonable, and the preparation method solves a shortcoming that the DHA algae oil is liable to oxidation anddeterioration. Xanthan gum, CMC, pectin, modified starch, gelatin, sucrose ester and other stabilizers are compounded to obtain a compound stabilizer, water-bath heating enables the compound stabilizer to be easily dissolved, and the preparation method greatly improves storage stability of the DHA-containing peanut yoghurt and improves shelf life.

Owner:WUHAN POLYTECHNIC UNIVERSITY

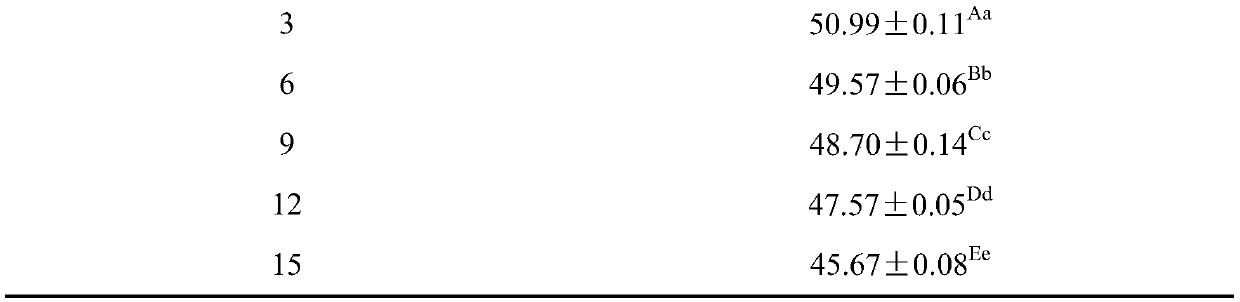

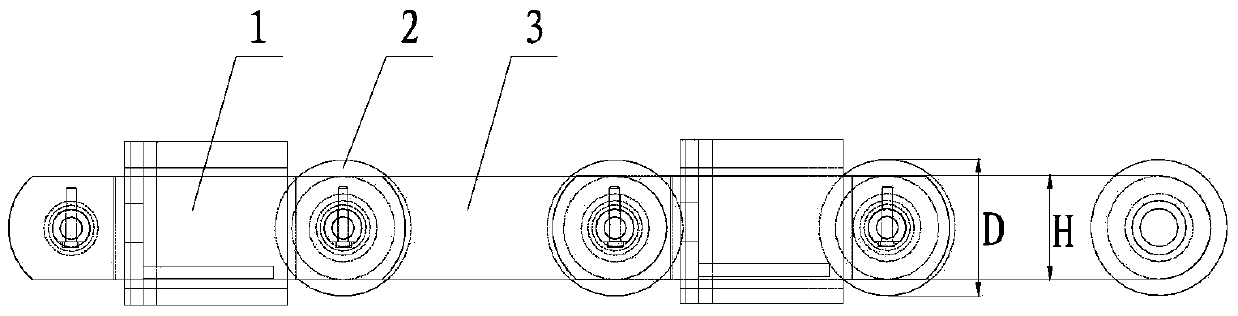

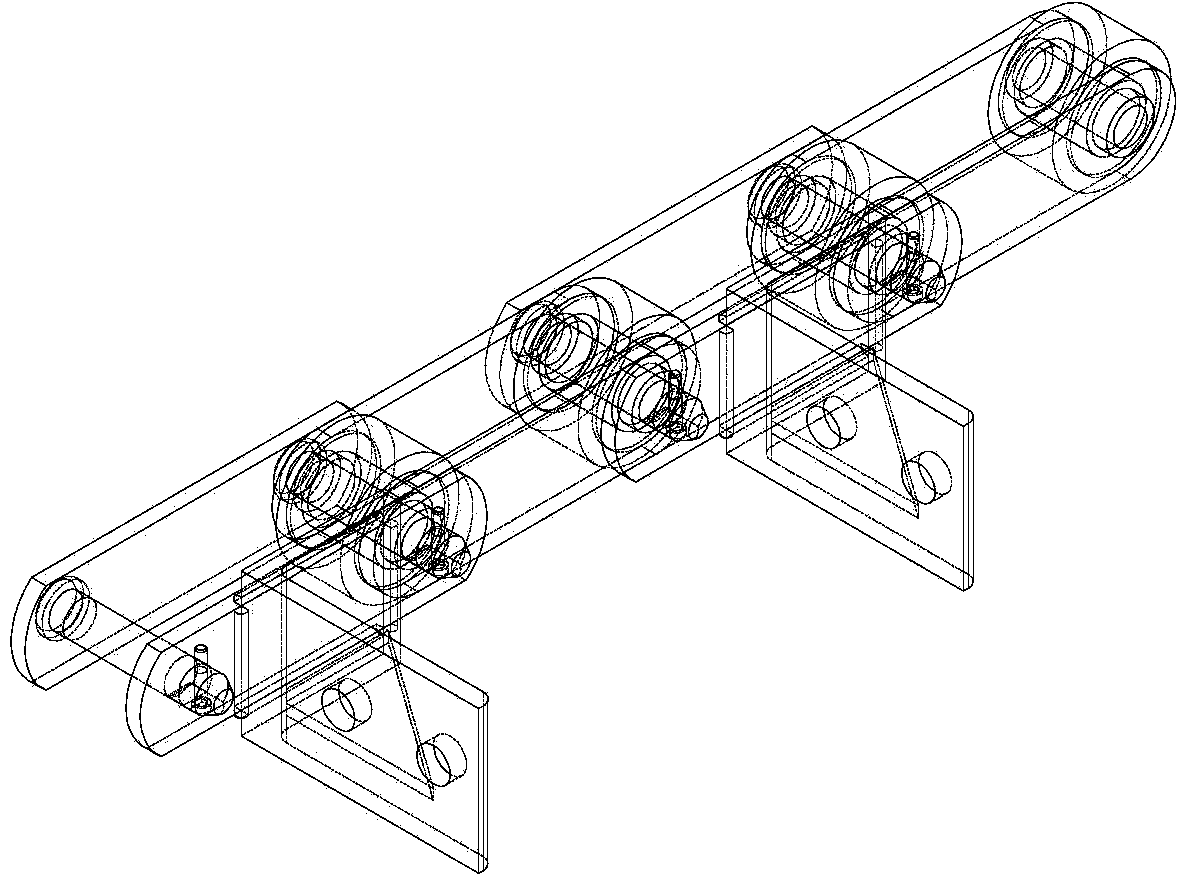

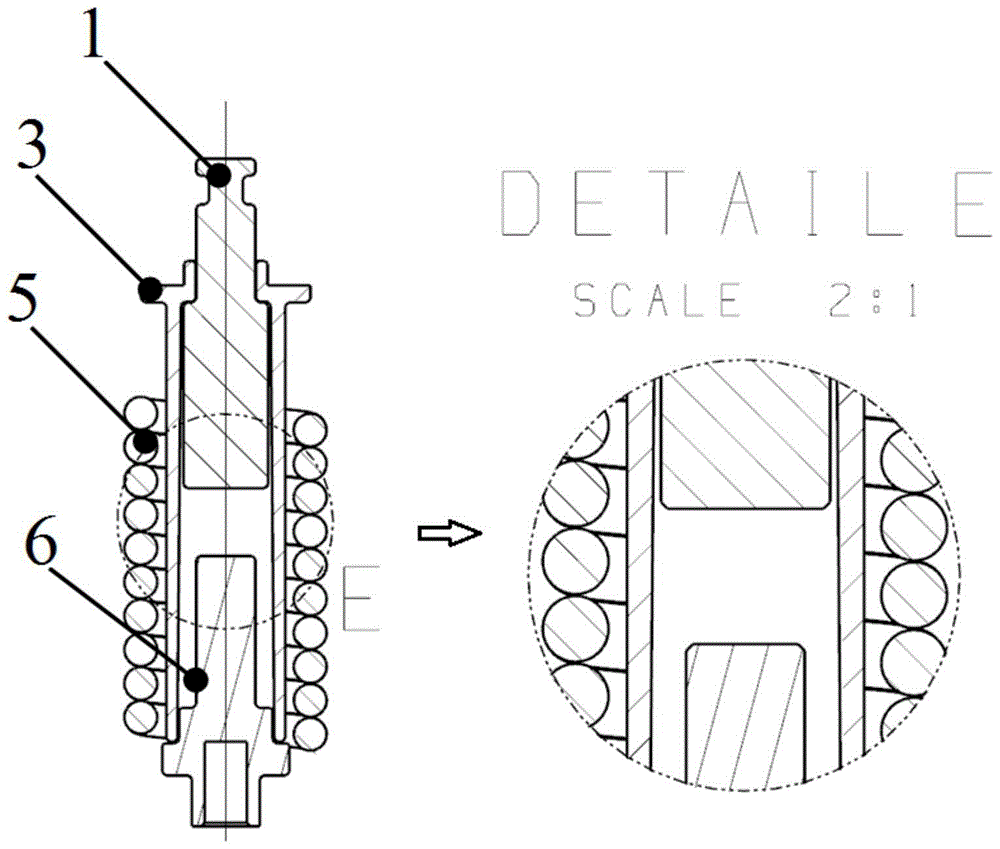

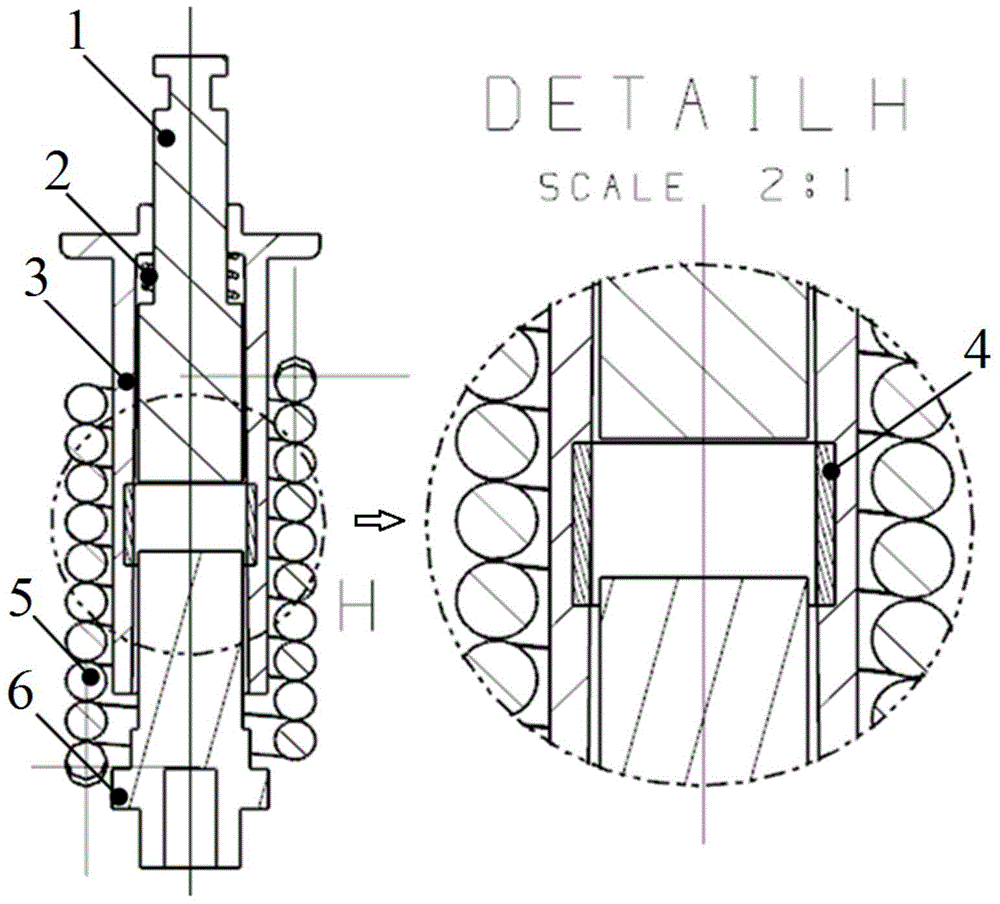

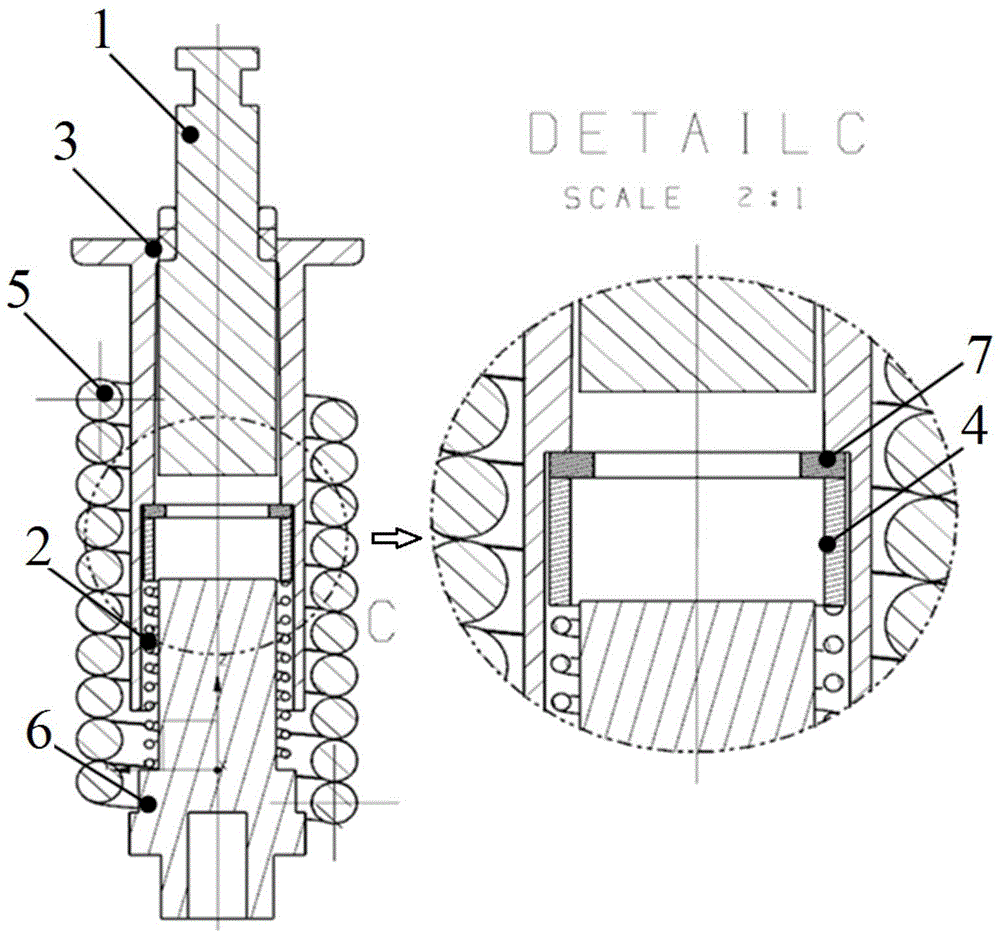

Abrasion-resisting chain

InactiveCN103496554AAvoid crushing the chainExtended service lifeConveyorsAgricultural engineeringChain link

The invention relates to an abrasion-resisting chain. The abrasion-resisting chain comprises a plurality of chain link units which are connected in an end-to-end mode. Each chain link unit comprises two chain boards which are arranged side by side, the chain boards of every two adjacent chain link units are connected through connecting shafts, a shaft sleeve is fixedly installed on each connecting shaft coaxially, the two ends of each shaft sleeve abut against the inner lateral walls of two corresponding chain boards respectively, an abrasion-resisting sleeve is coaxially arranged on the outer side of each shaft sleeve in a sleeved mode, and the diameter of each abrasion-resisting sleeve is larger than the height of each chain board. The abrasion-resisting chain is ingenious in design, reasonable in improvement, simple in structure, high in abrasion resistance, long in service life, and particularly suitable for transportation of heavy goods.

Owner:TIANJIN YUNZHOU MACHINERY PARTS

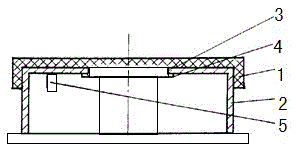

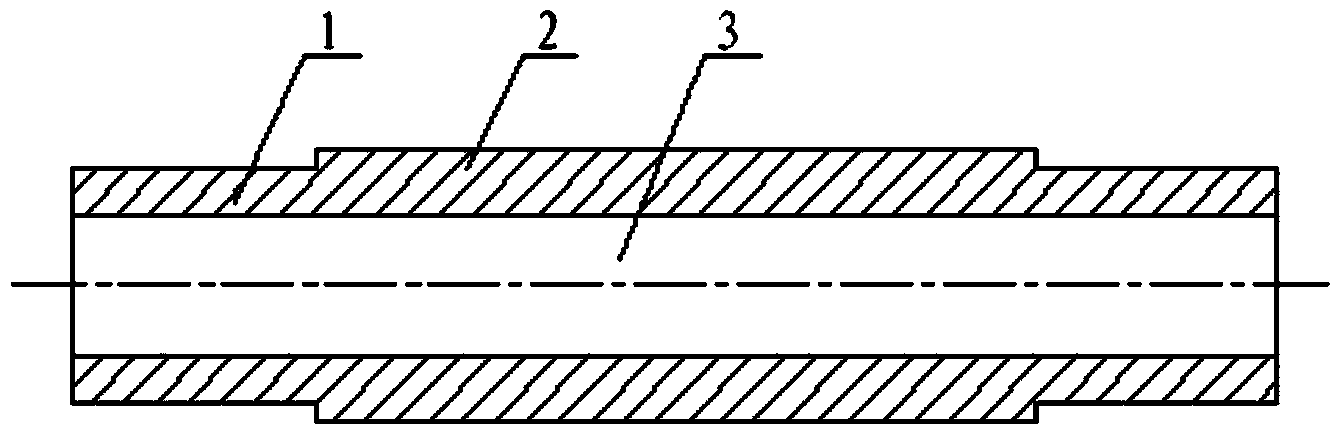

A controllable electromagnetic tripping device and tripping method with added magnetic conductor

ActiveCN104810217BReduce air gapIncrease electromagnetic attractionProtective switch operating/release mechanismsStructural engineeringShort circuit protection

The invention discloses a magnetizer-added controllable electromagnetic trip device and a tripping method and belongs to the technical field of electromagnetic trip devices. The device comprises a movable iron core, an outer sleeve, a coil and a statistic iron core; the outer sleeve sleeves the movable iron core and the statistic iron core; the movable iron core performs linear motions relative to the statistic iron core; the coil wraps the outer sleeve; a magnetizer is added between the movable iron core and the statistic iron core, and the position of the magnetizer corresponding to the movable iron core and the statistic iron core is adjustable. The air gap between the movable iron core and the statistic iron core is changed by adjusting the position of the magnetizer corresponding to the movable iron core and the statistic iron core; the rated current can be controlled in the certain range, the purpose of providing instantaneous short circuit protection for circuit breakers with various rated currents is achieved, and the higher maneuverability and adjustability are provided.

Owner:NANJING DAQO ELECTRICAL INST CO LTD

Full-function closed cyclic treatment and utilization system for comprehensive waste

InactiveCN102153376BLow costWell mixedBio-organic fraction processingClimate change adaptationLiquid wasteCompound organic

The invention relates to a full-function closed cyclic treatment and utilization system for comprehensive waste, which comprises a household solid waste treatment subsystem, a sewer-discharged liquid sedimentary waste treatment subsystem, a slime processing subsystem, a comprehensive waste mixing and molding subsystem and a finished fertilizer adding subsystem. The invention is characterized in that the solid waste treatment subsystem, the discharged liquid sedimentary waste treatment subsystem, the slime processing subsystem, the finished fertilizer adding subsystem and the comprehensive waste mixing and molding subsystem are connected with each other; and remaining solid waste, liquid waste, auxiliary molding materials and fertilizer effect additives which are subjected to preceding sorting treatment are classified and output to the mixing and molding subsystem according to a physical processing classification method, and are mixed and molded into compound organic fertilizers for different purposes according to a certain size. The waste treatment method based on the system realizes the low-cost mixing due to physical adhesive properties of the liquid and solid waste and the slime, and realizes the rational utilization due to the value of the waste which can be used as the organic substance, thereby changing the waste into fertilizer, causing no secondary pollution and generating no redundancy. The invention can be conveniently implemented and used for production.

Owner:TONGLU TIANYI TECH

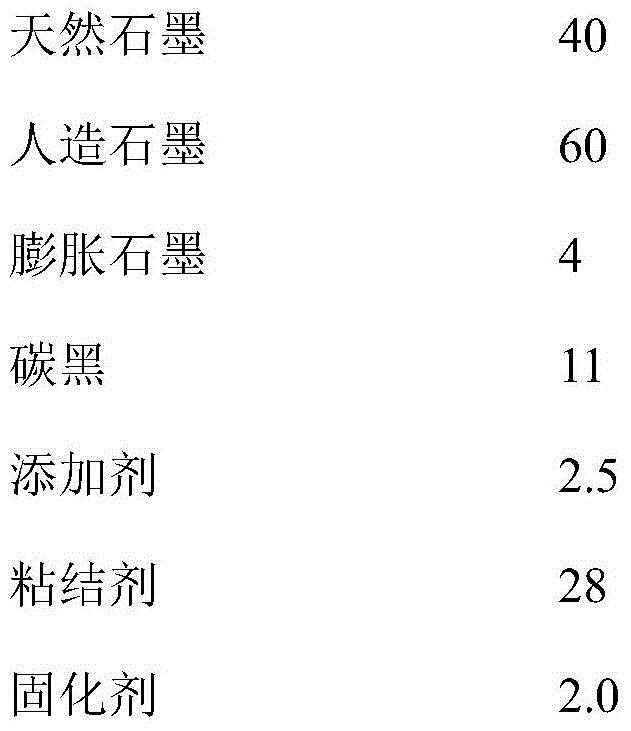

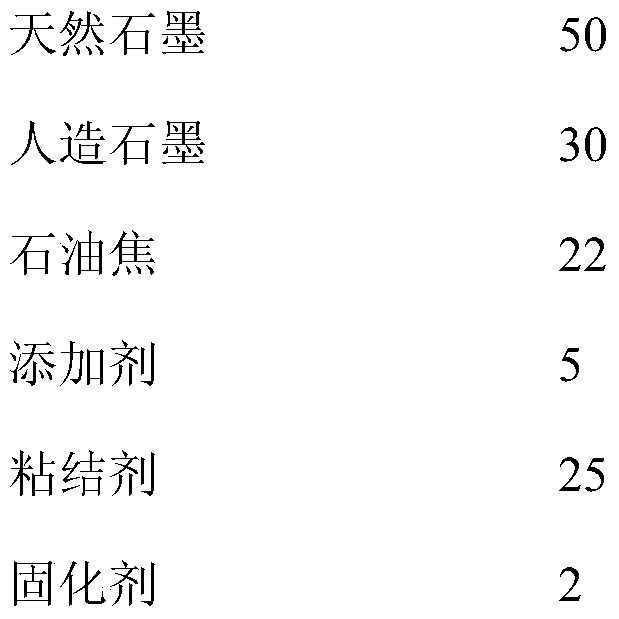

Preparation method of electric brush for treadmill motor and electric brush prepared by the method

ActiveCN104779511BImprove wear resistanceReduce noiseRotary current collectorBrushes manufactureElectrical resistance and conductancePunching

The present invention discloses a manufacturing method of an electric brush for a treadmill motor and an electronic brush manufactured using the method. The materials of the electric brush for the motor belong to the field of material science. The manufacturing method of the electric brush comprises: firstly, uniformly mixing graphite, carbon black, an additive, an adhesive and a firming agent under a condition of heating, then smashing and placing the mixture in a mold, and shaping the mixture via pressing; and secondly, conducting curing treatment, cutting, grinding, punching and line adding. The electric brush for the treadmill motor manufactured using the method is low in noise caused during operation, low in resistance, good in direction switching performance, powerful in interference resistance and long in service life. most importantly, the electric brush is high in abrasion resistance, low in noise and spark grade, sparkless in empty load, and good in product stability.

Owner:SUZHOU DONSUN CARBONWARE CO LTD

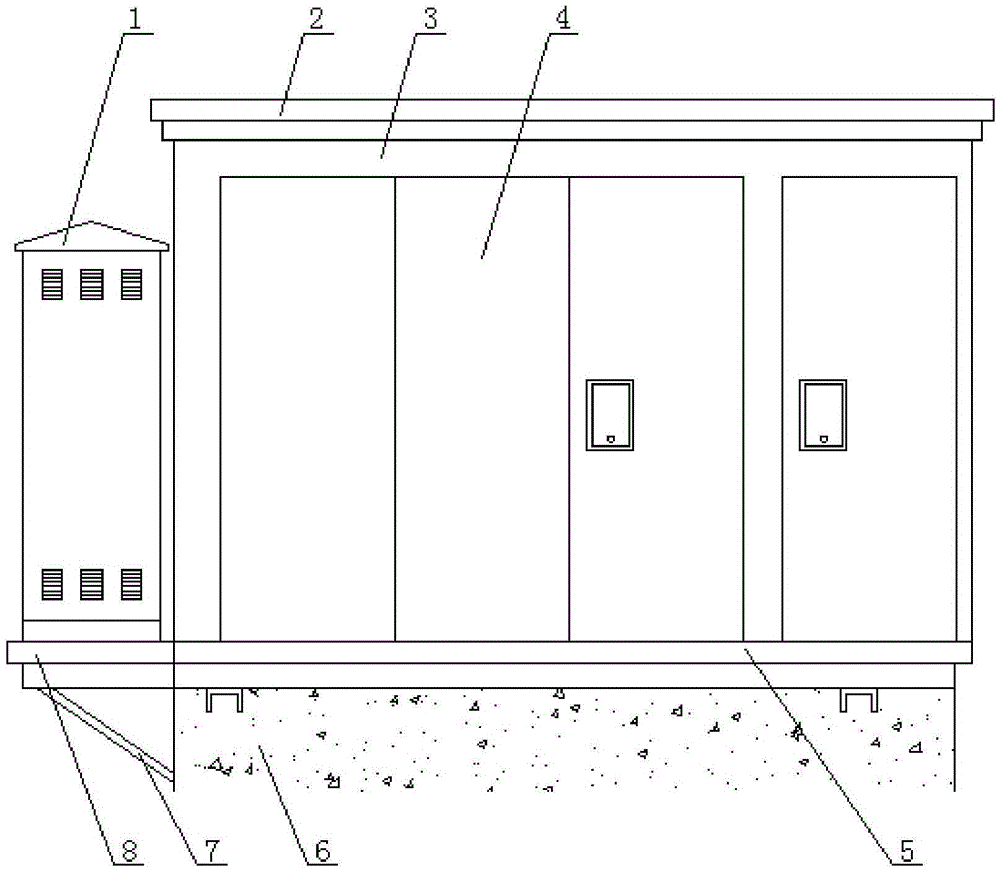

External comprehensive box type cement switching station

InactiveCN105490179AReduce construction difficultyImprove construction progressSubstation/switching arrangement detailsEngineeringCement

The invention relates to an external comprehensive box type cement switching station, comprising a box body, a base, a box cover and a cabinet door, wherein the box body is mounted on the base, the box cover covers the box body, the cabinet door is mounted on the front side of the box body, the base of the box body extends outwards horizontally to form a mounting platform for mounting a comprehensive box, and the lower bottom of the mounting platform is suspended in the air and is welded and mounted on the base. The external comprehensive box type cement switching station is smart in design, reasonable in improvement and high in practicability. The invention takes modification with a clear target after reasonable analysis according to the difficulties in construction, therefore the external comprehensive box type cement switching station has high practicability, not only can meet the requirement for site operation, but also has the advantages of short power failure time, low construction cost and simple and convenient later-stage maintenance and thus is suitable for generalization and use.

Owner:天津三源电力智能科技有限公司

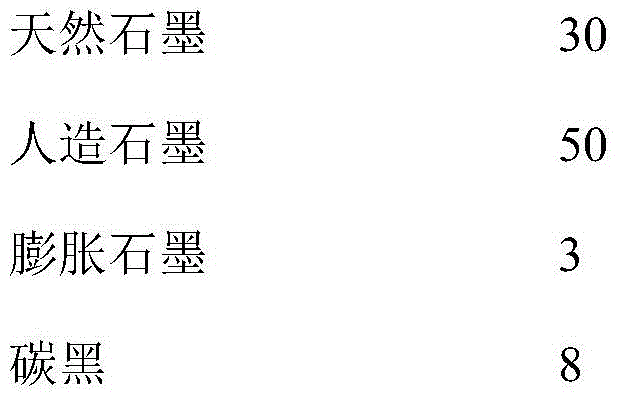

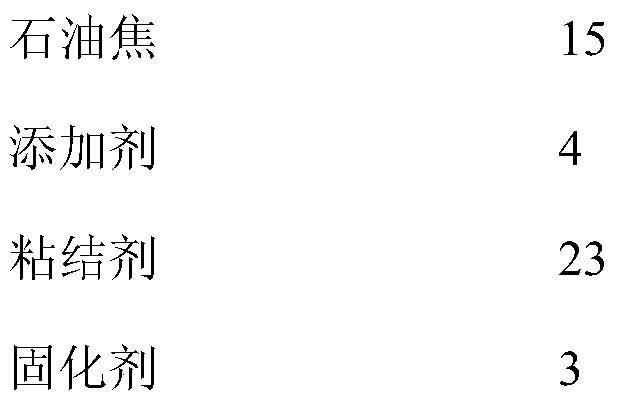

Preparation method of electric brush for vacuum cleaner motor and electric brush prepared by the method

ActiveCN105322410BImprove wear resistanceReduce noiseRotary current collectorBrushes manufactureAgricultural engineeringGraphite

The invention discloses a vacuum cleaner high-speed high-efficiency motor brush preparation method and a brush prepared by the method. Constituent materials of the motor brush belong to the field of material science. The brush preparation method comprises, to begin with, mixing graphite, petroleum coke, additive, binders and curing agents uniformly under an ambient temperature condition, smashing the mixture and then, placing the smashed mixture into a die; carrying out compression moulding; and then, carrying out curing processing, cutting, grinding machine, hole drilling and line filling. The vacuum cleaner high-speed high-efficiency motor brush prepared by the method is low in resistance in the using process, good in commutating performance and long in service life, and more importantly, has high wear resistance, low spark grade and good product stability.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

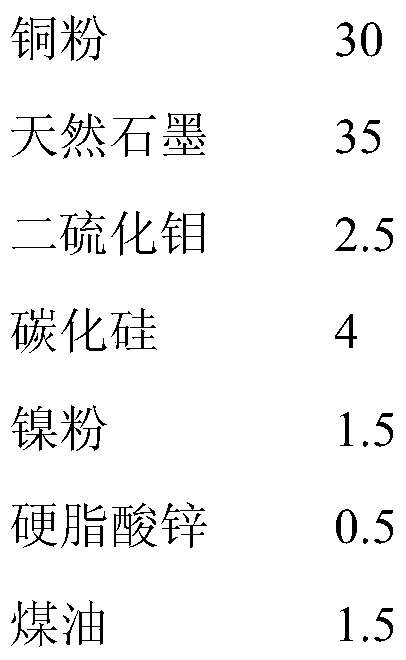

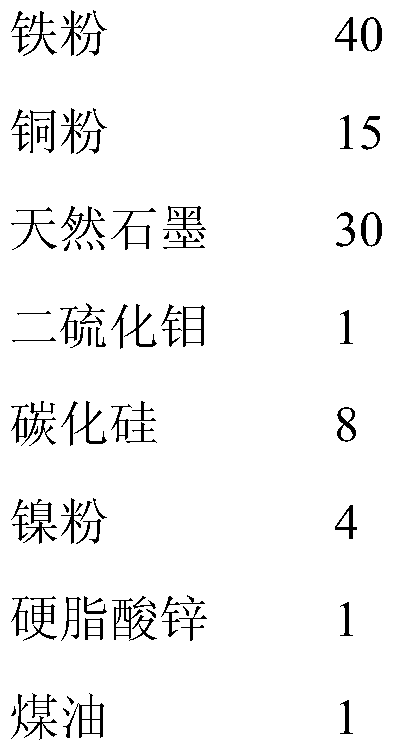

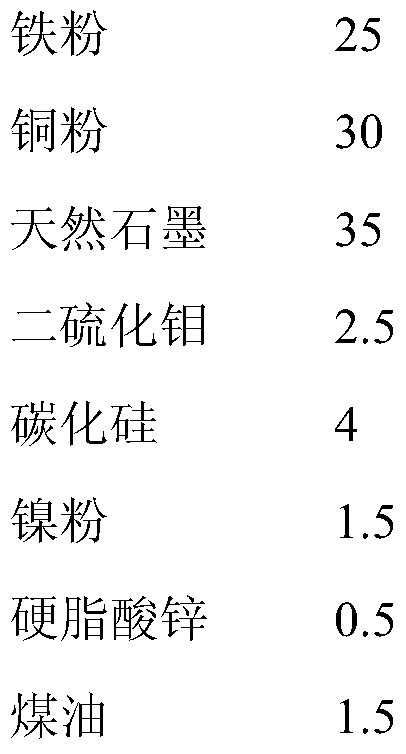

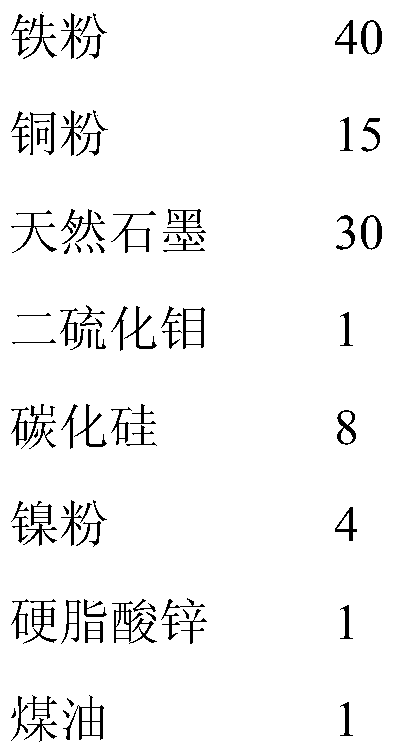

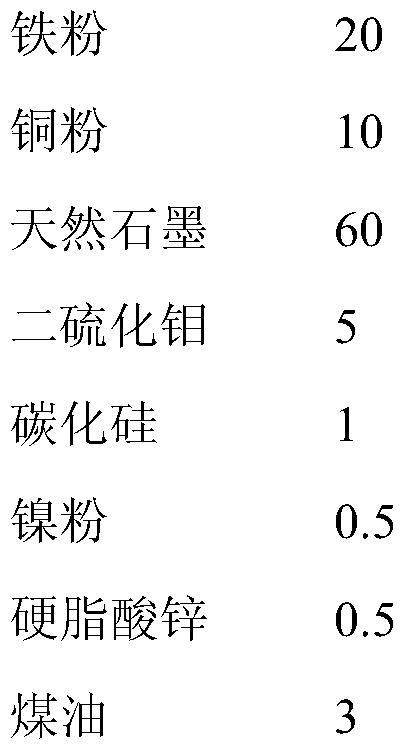

A preparation method of powder metallurgy brake shoe for electric locomotive

The invention provides a manufacturing method for a powder metallurgy brake shoe for an electric locomotive. The method comprises the steps that iron powder, copper powder, natural graphite, an additive and a lubricating agent are evenly mixed to obtain a premix; the premix is placed in a die to be pressed to obtain a tile-shaped powder metallurgy brake shoe friction block blank; the blank is sintered to obtain a powder metallurgy brake shoe friction block; the powder metallurgy brake shoe friction block and a steel backing are subjected to pressure sintering to obtain a brake shoe friction block assembly; a steel shoe, a retaining ring and a stop dog are subjected to combination welding treatment to obtain a brake shoe framework assembly, and the brake shoe framework assembly and the brake shoe friction block assembly are subjected to combination welding treatment to obtain a brake shoe blank; and the brake shoe blank is subjected to varnish dipping and painting treatment, and the powder metallurgy brake shoe is obtained, wherein the additive comprises molybdenum disulfide, silicon carbide and nickel powder, and the lubricating agent comprises zinc stearate and kerosene. The manufactured brake shoe for the locomotive is stable in frictional coefficient, small in attenuation and abrasion and good in heat conduction and has good physical, chemical and mechanical performance.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

Powder metallurgy brake shoe for electric locomotive

ActiveCN105987103BAdd reasonableLight in massBraking membersFriction liningKeroseneFrictional coefficient

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

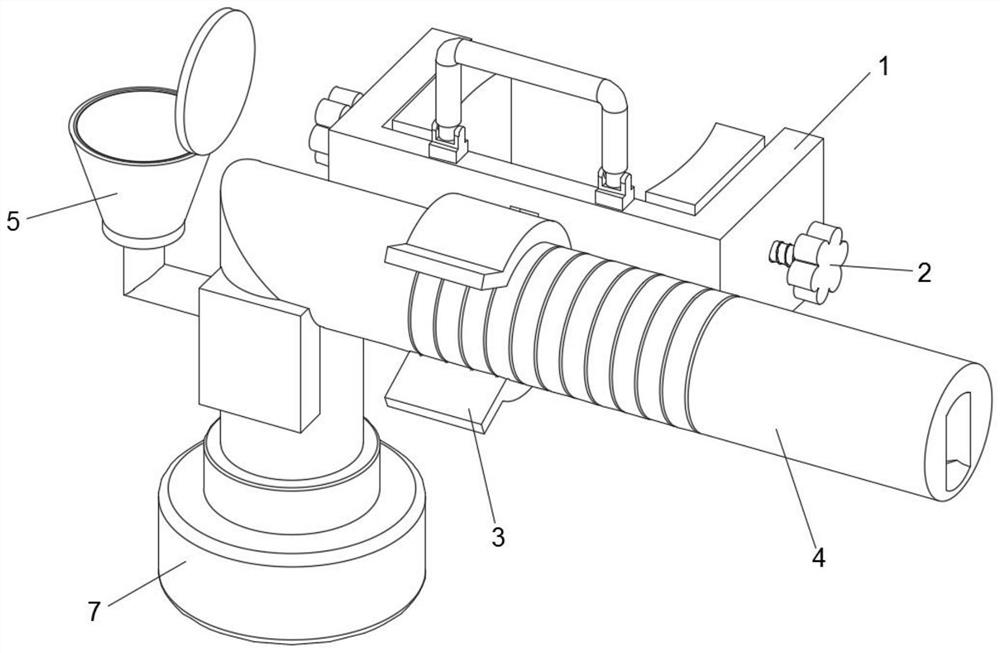

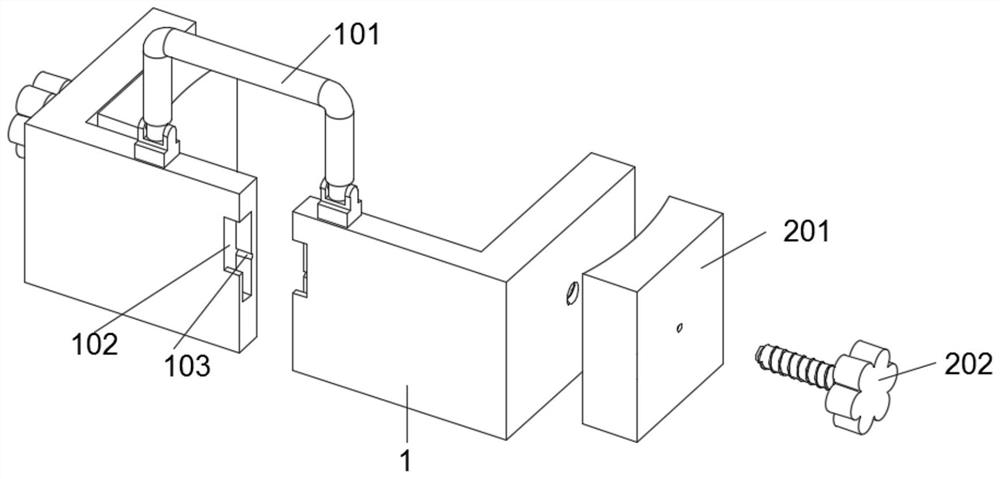

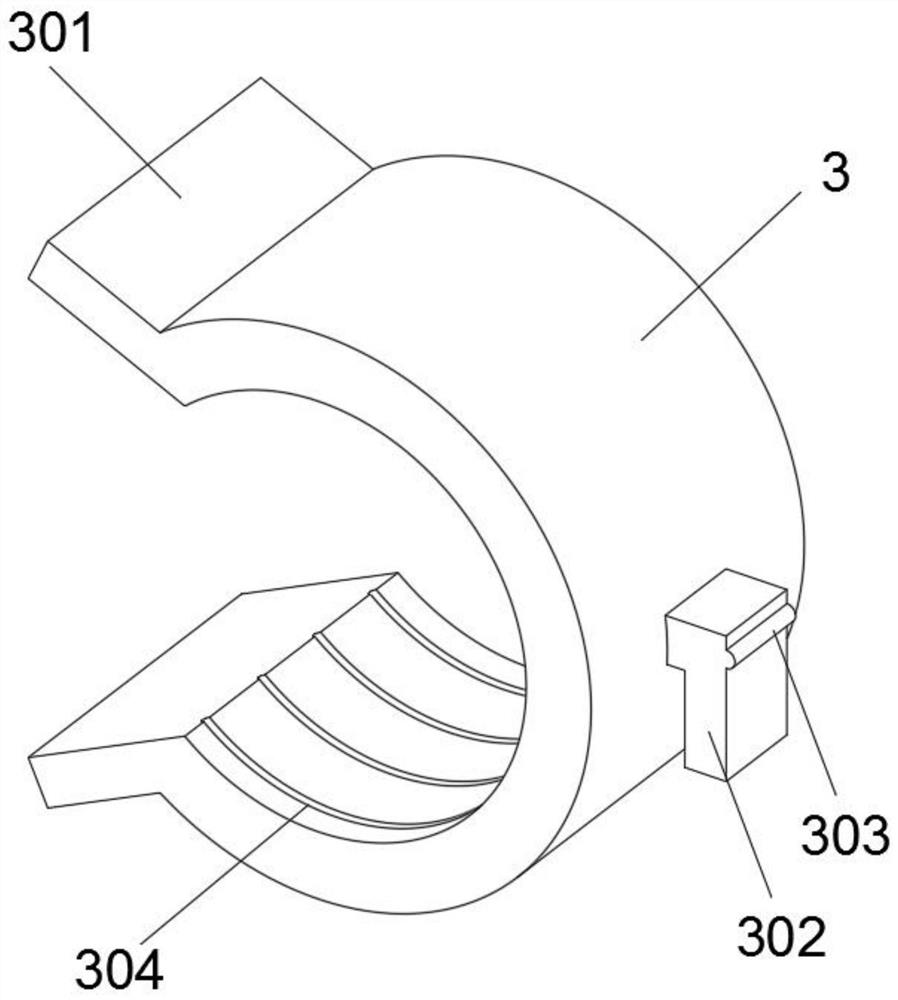

Forestry pest trapping device

ActiveCN112772594AEasy to handleEasy to addInsect catchers and killersAgainst vector-borne diseasesForest industryTrapping

The invention discloses a forestry pest trapping device, and belongs to the technical field of forestry engineering pest control. The forestry pest trapping device comprises a mounting base, a handle is mounted on the top surface of the mounting base, two clamping assemblies are symmetrically arranged at the left end and the right end of the mounting base, a clamping base is movably mounted at the front end of the mounting base, a trapping pipe is clamped in the clamping base, a trapping groove is formed in a transverse pipe of the trapping pipe, and a feeding assembly is rotationally connected to a vertical pipe of the trapping pipe; and a tiling assembly is arranged below the terminal of the feeding assembly, and the terminal of the vertical pipe of the trapping pipe is connected with a collecting bottle through screws. The forestry pest trapping device is installed at all positions in a garden through the mounting base, and the device can be clamped on a tree through screwing-in of the clamping assemblies; by means of the movably-installed clamping base, assembling of the device is facilitated, and the trapping pipe is conveniently installed movably; and the special labyrinth structure in the trapping pipe is utilized, so that after trapping agents are added into the feeding assembly on the trapping pipe, pests enter the trapping pipe along drifting smell, and then the trapping effect that the pests enter the trapping pipe easily and exit from the trapping pipe difficultly is achieved.

Owner:雄安爱树科技有限公司

Treatment plate

Owner:张永芳

Device with protruding part penetrating through inner cover

The invention discloses a device for a protrusion passing through an inner cover, which is characterized in that it includes an inner cover with a central hole and an easy-open indentation around the inner cover, and is characterized in that the outer cover is loosely fitted with the inner cover The half cover is placed on the inner cover, and the convex part on the reverse side of the outer cover passes through the central hole of the inner cover to form a flange and fix it with the inner cover. By adopting the above scheme, the present invention has simple structure, reasonable improvement, easy realization, fixed effect and prolonged service life.

Owner:赵越

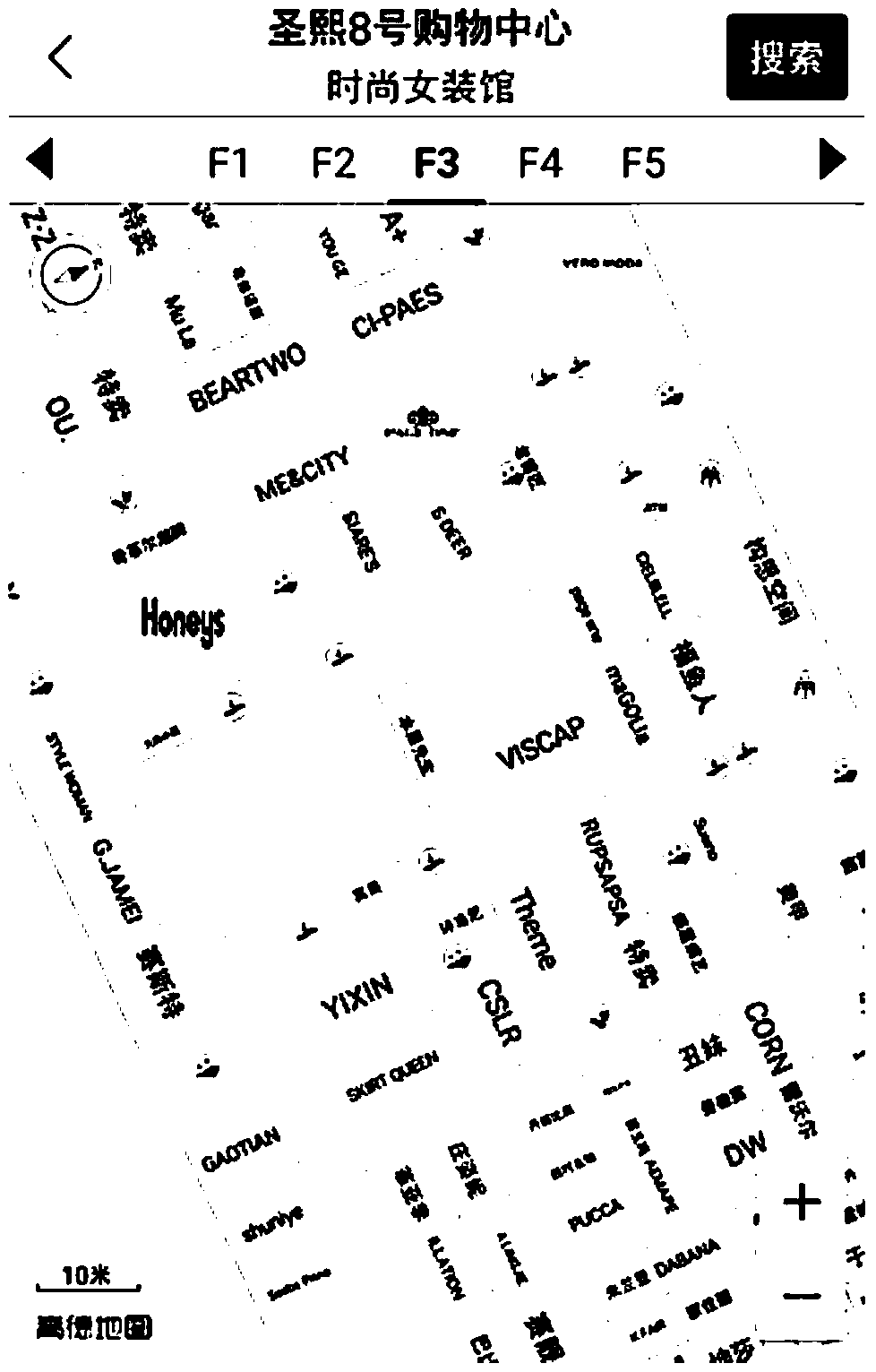

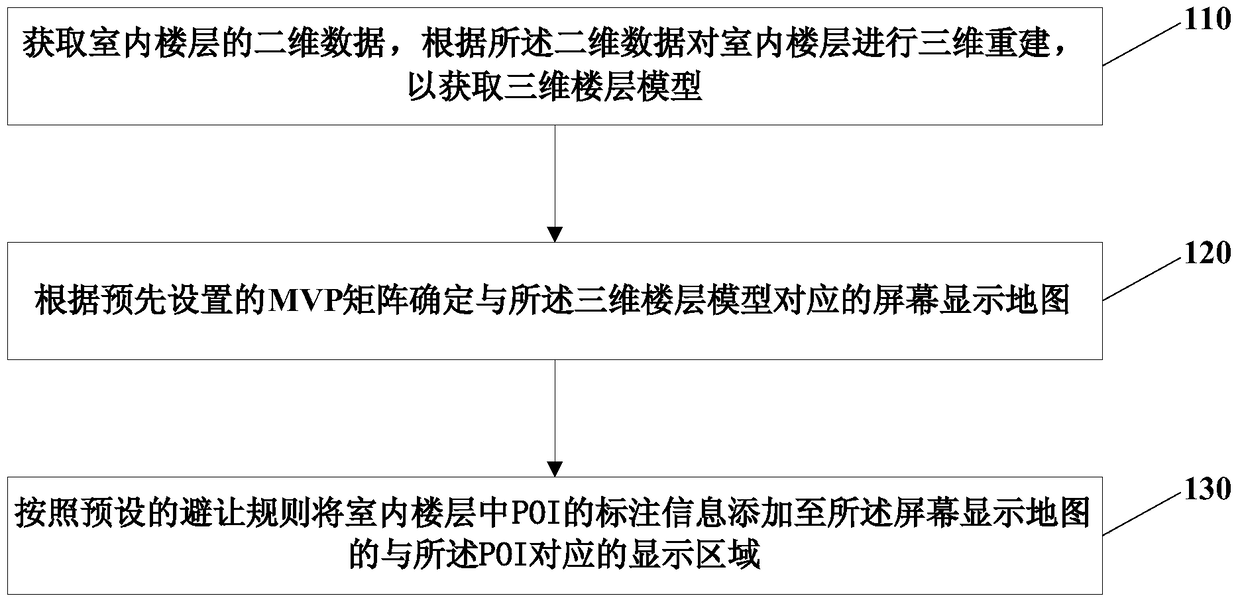

A POI labeling method and device

ActiveCN105183862BImprove the display effectAdd intuitiveSpecial data processing applicationsOn-screen displayComputer science

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

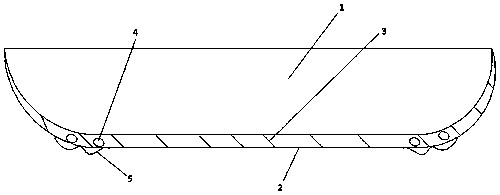

Medium chain sleeve for amphibious excavator

The invention relates to a medium chain sleeve for an amphibious excavator. The medium chain sleeve comprises a tubular medium sleeve body, a shaft hole is processed in the axis of the tubular medium sleeve body, an outer sleeve is processed on the outer side of the middle of the tubular medium sleeve body coaxially, and an upper end face and a lower end face, located on the left and right side of the outer sleeve, of the tubular medium sleeve body are processed into planes. The medium chain sleeve for the amphibious excavator is scientific in design, reasonable in improvement, easy to manufacture and convenient to used and is of an integrated structure, and the upper end face and the lower end face, located on the left and right side of the outer sleeve, of the tubular medium sleeve body are processed into the planes, so that sludge can be prevented from entering clearances, friction is reduced, and service life is prolonged.

Owner:TIANJIN QIANGLI CHAIN

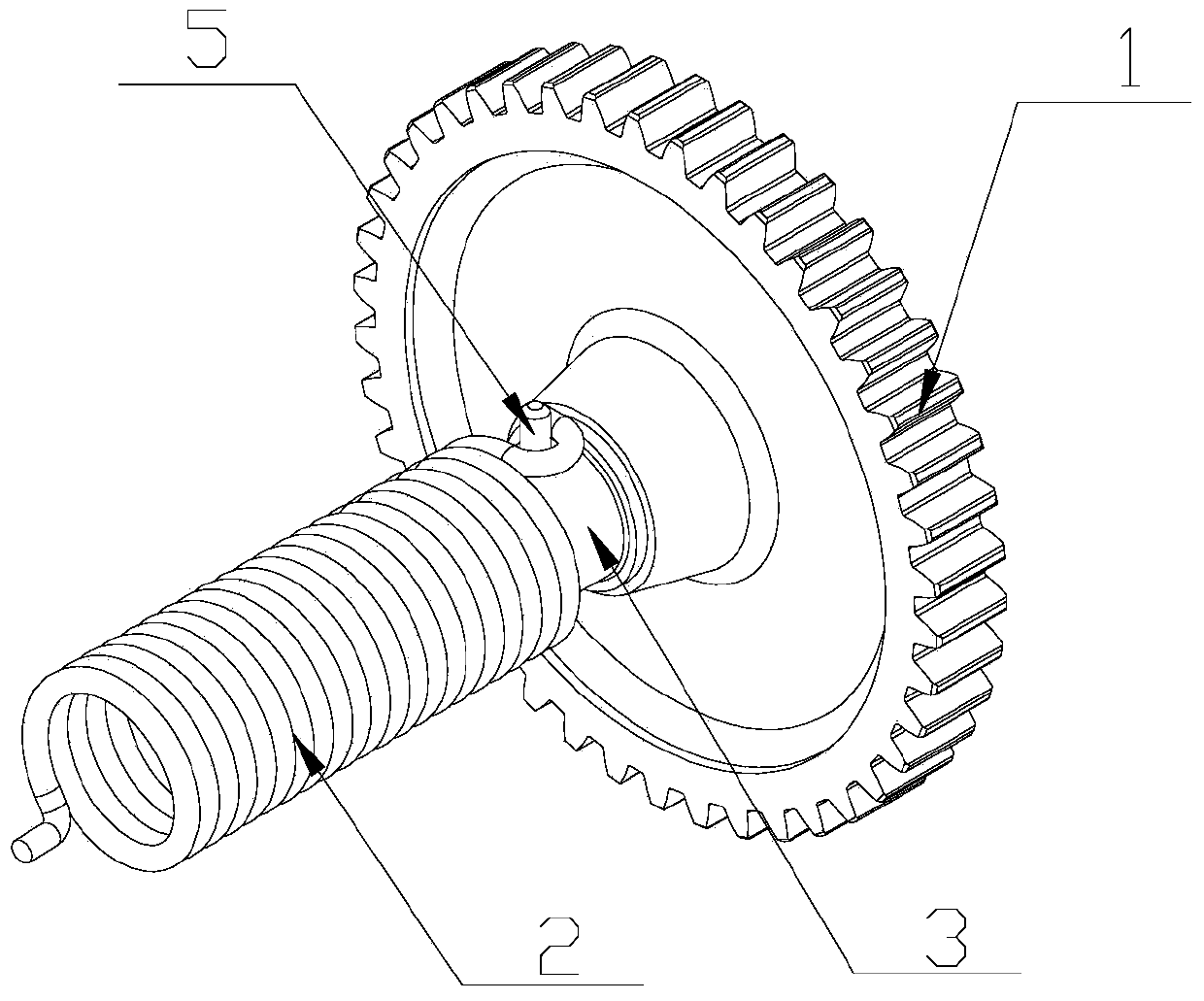

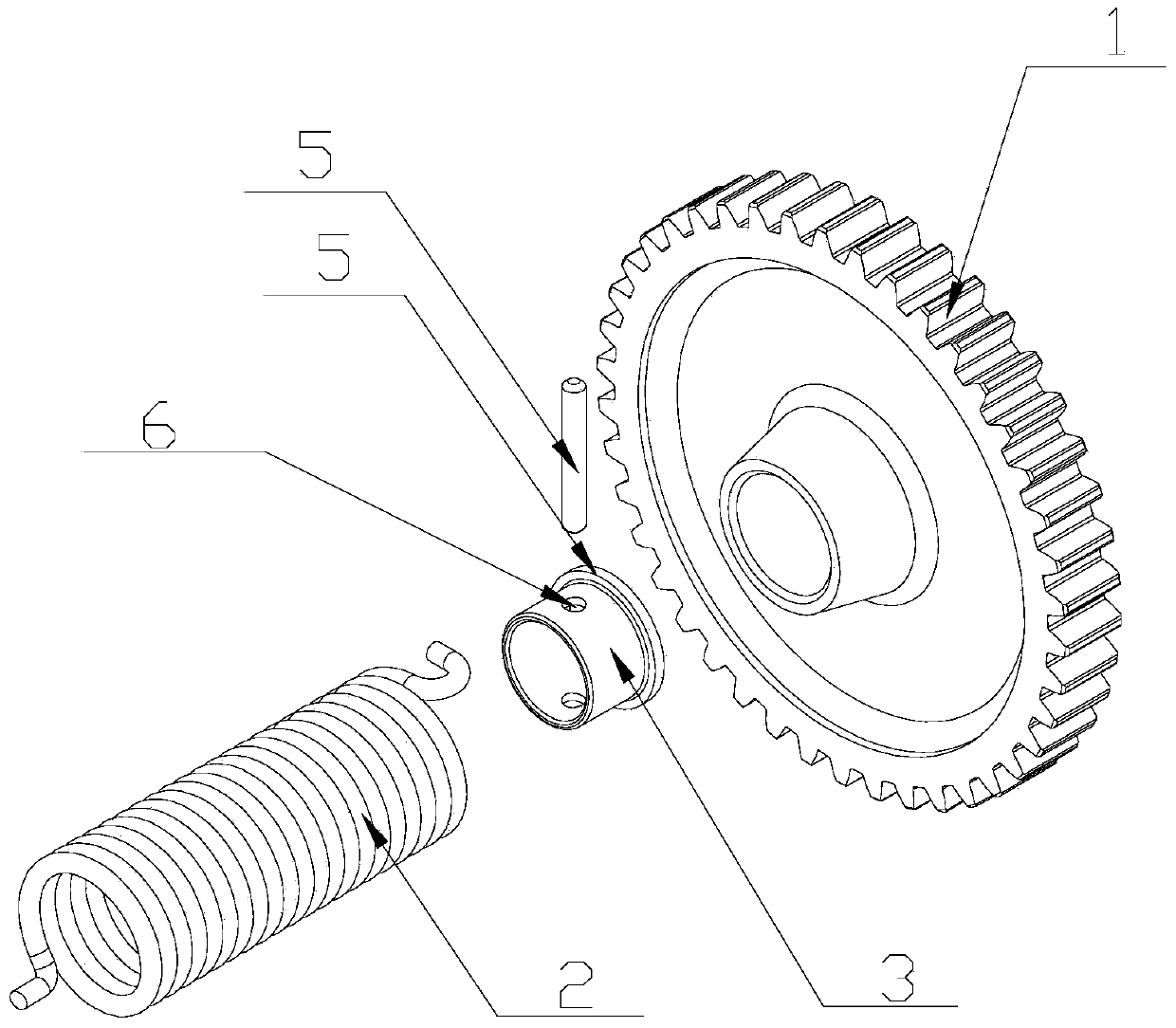

Starting gear structure on motorcycle starting shaft

The invention relates to a motorcycle engine part, in particular to a starting gear structure on a motorcycle starting shaft. The starting gear structure on the motorcycle starting shaft comprises a starting gear, a spring and a connecting piece located between the starting gear and the spring. The connecting piece is in a hollow cylinder shape, a flange is arranged at the edge of one end of the connecting piece and clamped into a hub of the starting gear, through holes for a positioning pin to be inserted into are formed in the connecting piece, and one end of the spring is fixed to the positioning pin. The starting gear structure is simple in structure and reasonable in improvement, a pair of carrier gears specially designed for foot starting in existing gear starting are removed, and the production cost is reduced.

Owner:徐亚珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com