A preparation method of powder metallurgy brake shoe for electric locomotive

A powder metallurgy and brake shoe technology is applied in the preparation of powder metallurgy brake shoes for medium and low-speed electric locomotives, and in the field of electric locomotive brake pads. Excellent processing performance, good lubricating performance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

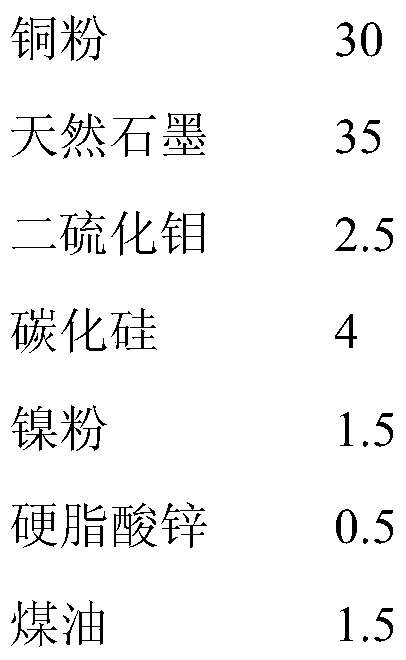

[0096] 1. Prepare the raw materials according to the following proportions by weight:

[0097]

[0098]

[0099] 2. Under normal temperature, iron powder, copper powder, additives and zinc stearate are uniformly mixed to obtain the first premix; then natural graphite and kerosene are uniformly mixed to obtain the second premix; The first premix and the second premix were added to the mixing equipment and mixed for 7 hours to prepare the premix.

[0100] 3. Put the premixed material in a mold for pressing treatment. The pressing equipment is a 315-ton hydraulic press with a pressing specific gravity of 5.3 to obtain a tile-shaped powder metallurgy brake shoe friction block blank.

[0101] 4. Roast the tile-shaped powder metallurgy brake shoe friction block blank, firstly increase the temperature of the sintering furnace to 1050°C within 5.5 hours, then keep it at this temperature for 4.5 hours, and then cool it to room temperature with cold water to obtain A tile-shaped ...

Embodiment 2

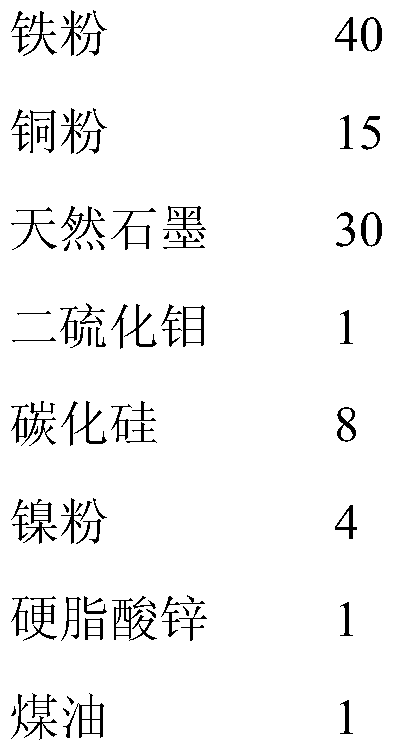

[0108] 1. Prepare the raw materials according to the following proportions by weight:

[0109]

[0110] 2. Under normal temperature, iron powder, copper powder, additives and zinc stearate are uniformly mixed to obtain the first premix; then natural graphite and kerosene are uniformly mixed to obtain the second premix; The first premix and the second premix were added to the mixing equipment and mixed for 6 hours to prepare the premix.

[0111] 3. Put the premixed material in a mold for pressing treatment. The pressing equipment is a 315-ton hydraulic press with a pressing specific gravity of 5.6 to prepare a powder metallurgy brake shoe friction block blank.

[0112] 4. Roast the powder metallurgy brake shoe friction block blank, firstly increase the temperature of the sintering furnace to 1000°C within 5 hours, then keep it at this temperature for 6 hours, and then cool it to room temperature with cold water to obtain a tile-shaped powder metallurgy Brake shoe friction b...

Embodiment 3

[0119] 1. Prepare the raw materials according to the following proportions by weight:

[0120]

[0121] 2. Under normal temperature, iron powder, copper powder, additives and zinc stearate are uniformly mixed to obtain the first premix; then natural graphite and kerosene are uniformly mixed to obtain the second premix; The first premix and the second premix were added to the mixing equipment and mixed for 10 hours to prepare the premix.

[0122] 3. Put the premixed material in a mold for pressing treatment. The pressing equipment is a 315-ton hydraulic press with a pressing specific gravity of 5.0 to prepare a powder metallurgy brake shoe friction block blank.

[0123] 4. Roast the powder metallurgy brake shoe friction block blank, firstly increase the temperature of the sintering furnace to 1100°C within 6 hours, then keep it at this temperature for 3 hours, and then cool it to room temperature with cold water to obtain a tile-shaped powder metallurgy Brake shoe friction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com