Preparation method of electric brush for vacuum cleaner motor and electric brush prepared by the method

A technology for vacuum cleaners and electric brushes, which is applied in the manufacture of brushes, circuits, and current collectors. It can solve the problems of poor stability of domestic brushes, failure to meet customer requirements, and poor resistance stability coefficients, etc., and achieve excellent mechanical processing performance. Good reversing performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

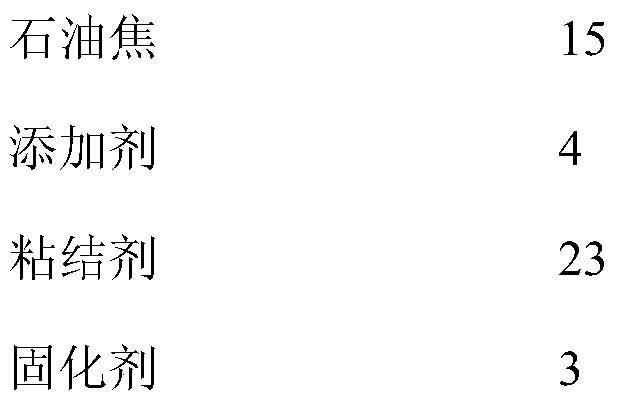

[0062] 1. Prepare materials according to the following weight ratio (kg):

[0063]

[0064]

[0065] Among them, the additives include molybdenum disulfide and carbon fiber, the weight ratio of molybdenum disulfide and carbon fiber is 1.5:2.5; the length of carbon fiber is 1-5mm, preferably 1-3mm; the binder is bisphenol A epoxy resin, Its epoxy value is 0.25-0.45; the curing agent is a latent curing agent T-31 curing agent (Changzhou Shanfeng Chemical Co., Ltd); the selected particle size of the petroleum coke is 300-400 mesh spherical cooked coke, preferably 300 mesh ;

[0066] 2) Put the raw materials of natural graphite, artificial graphite, petroleum coke, additives, and curing agent in the kneading pot, turn on the stirring device of the kneading pot, mix at a constant temperature (20°C) for 2 hours, and stop discharging to obtain a premix ;

[0067] 3) the binder epoxy resin of 23kg is dissolved in the acetone of 42kg, mix homogeneously, make binder solution;

...

Embodiment 2

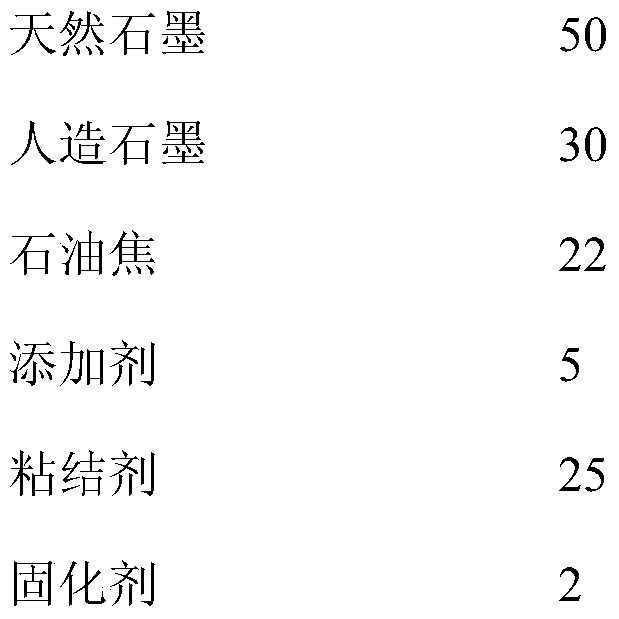

[0077] 1. Prepare materials according to the following weight ratio (kg):

[0078]

[0079] Among them, the additives include molybdenum disulfide and carbon fiber, the weight ratio of molybdenum disulfide and carbon fiber is 1.5:3.5; the length of carbon fiber is 1-3mm; the binder is bisphenol A epoxy resin, and its epoxy value is 0.25 -0.35; the curing agent is a latent curing agent adipate dihydrazide (Wuxi Liangxi Fine Chemical Co., Ltd); the selected particle size of the petroleum coke is 300-400 mesh needle-shaped cooked coke;

[0080] 2) Put the raw materials of natural graphite, artificial graphite, petroleum coke, additives, and curing agent in the kneading pot, turn on the stirring device of the kneading pot, mix at a constant temperature (25°C) for 1.5 hours, and then stop discharging to obtain a premix;

[0081] 3) the adhesive epoxy resin of 25kg is dissolved in the acetone of 50kg, mix homogeneously, make adhesive solution;

[0082] 4) Add the binder solution...

Embodiment 3

[0089] 1. Prepare materials according to the following weight ratio (kg):

[0090]

[0091] Among them, the additives include molybdenum disulfide and carbon fiber, the weight ratio of molybdenum disulfide and paraffin wax is 1.5:3; the length of carbon fiber is 1-5mm; the binder is bisphenol A epoxy resin, and its epoxy value is 0.25 -0.35; the curing agent is a latent curing agent adipate dihydrazide (Wuxi Liangxi Fine Chemical Co., Ltd); the selected particle size of the petroleum coke is 300-400 mesh spherical cooked coke;

[0092] 2) Put the raw materials of natural graphite, artificial graphite, petroleum coke, additives, and curing agent in the kneading pot, turn on the stirring device of the kneading pot, mix at a constant temperature (35°C) for 2.5 hours, and then discharge to obtain a premix ;

[0093] 3) the binder epoxy resin of 18kg is dissolved in the acetone of 39.6kg, mix homogeneously, make binder solution;

[0094] 4) Add the binder solution into the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com