Welding process for equal-diameter large quartz pipes

A welding process and quartz technology, applied in the field of welding process of large diameter quartz tubes, can solve the problems of high welding qualification rate, insufficient length of small-sized quartz tubes, and high difficulty in adding solder, so as to improve the welding yield, rotation safety and convenience. , good welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: prepare a diameter and be 465mm, the quartz large tube that length is 2500mm

[0039] Include the following steps:

[0040] A. Take two large quartz tubes with a length of 2000mm and a diameter of 465mm, cut one of them to obtain a tube A with a length of 550mm for use, and then take an uncut tube B with a length of 2000mm for use, and carry out the two tubes respectively unilateral pour;

[0041] B. Clean and dry the pour end;

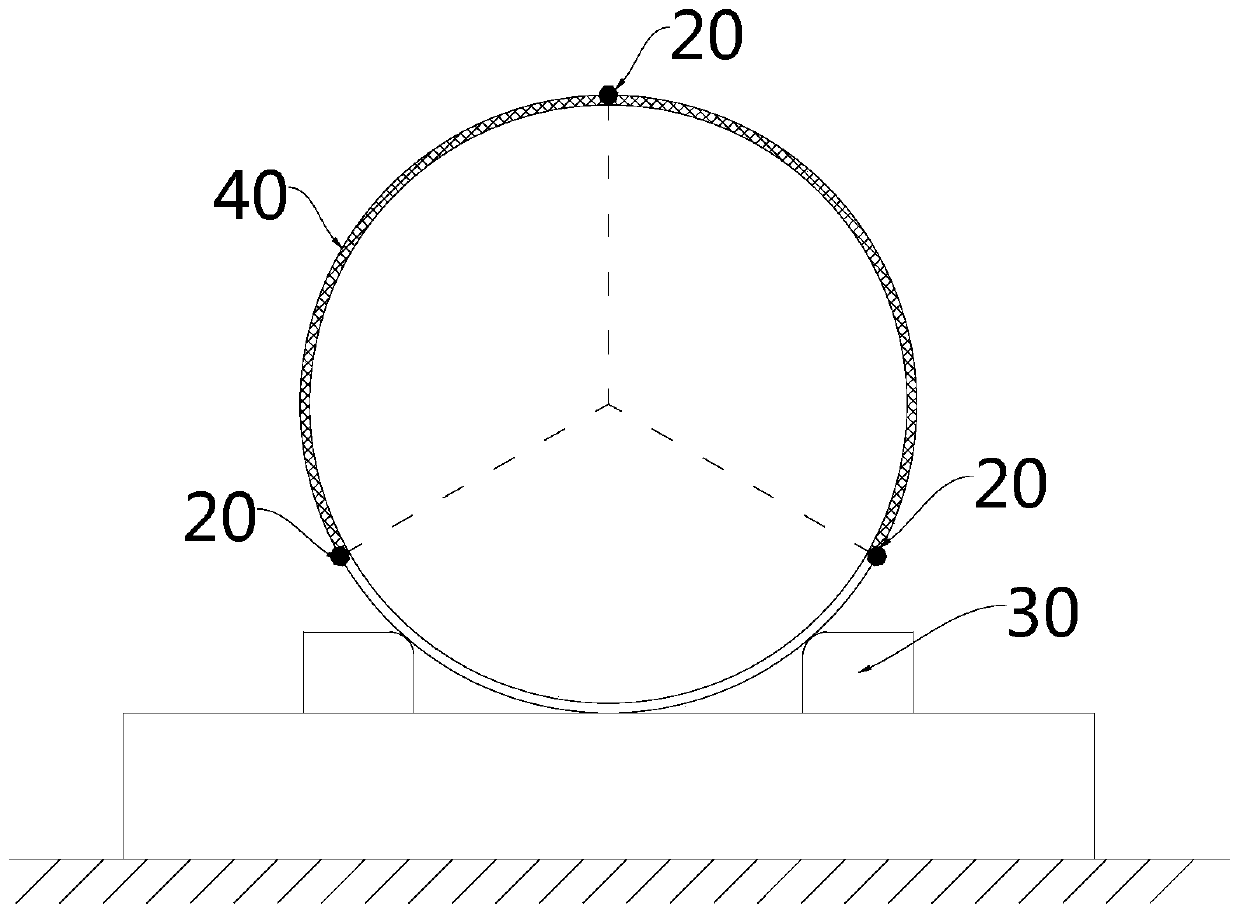

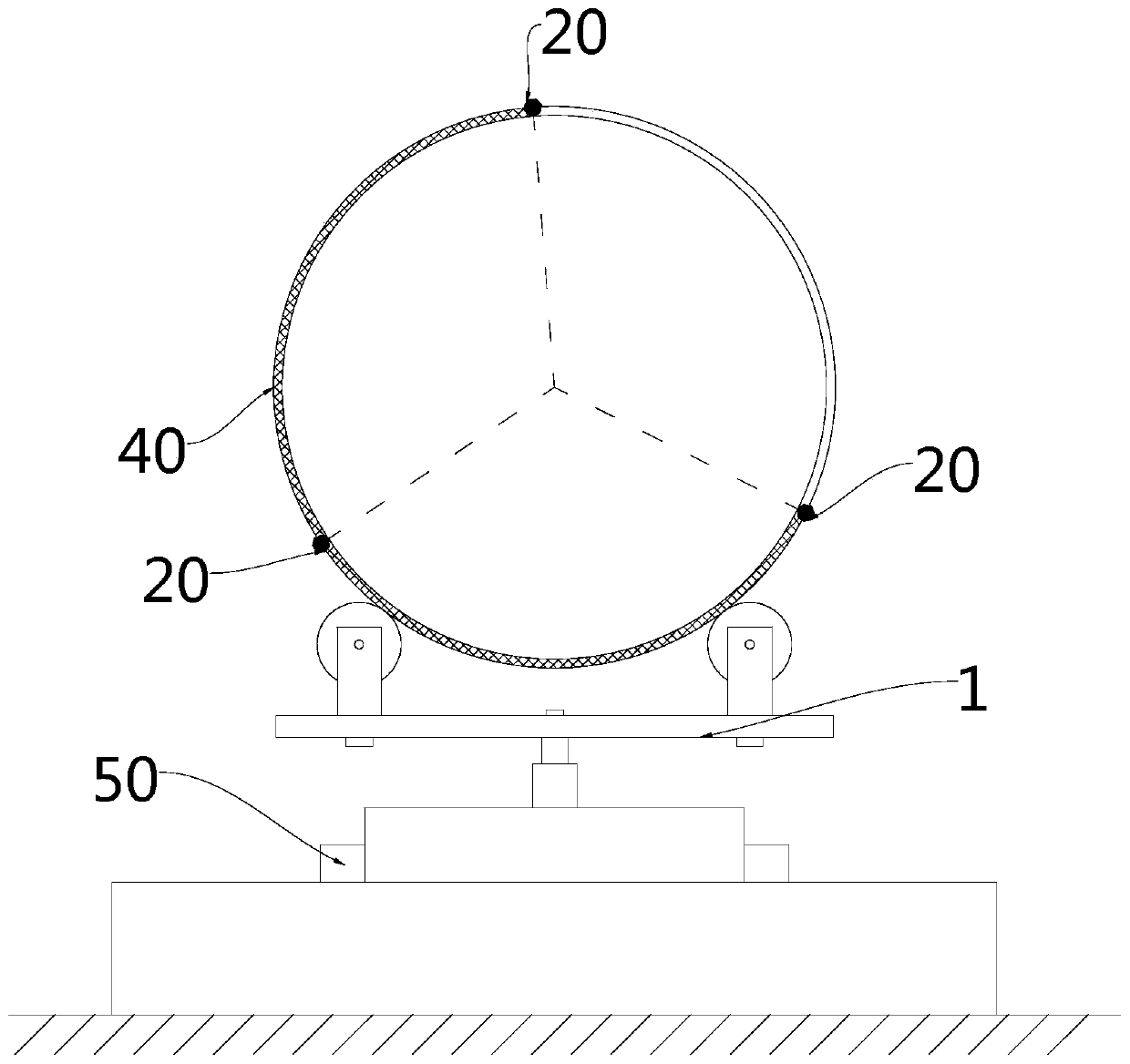

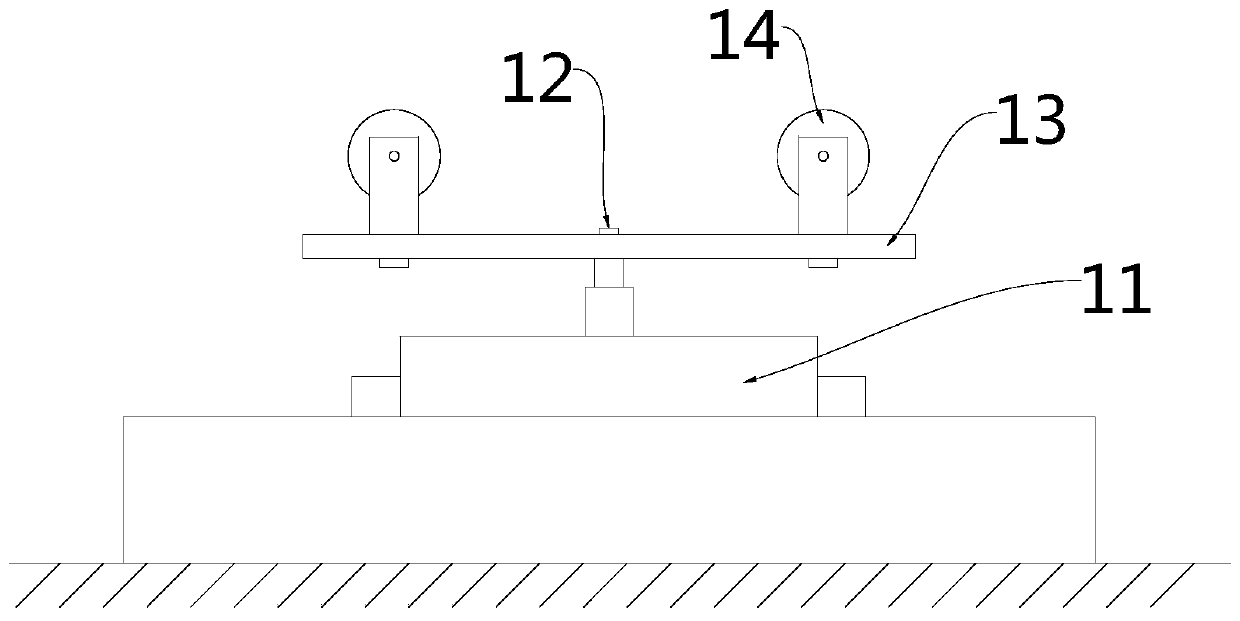

[0042]C. Put the pour ends of tube A and tube B facing each other and keep the axis horizontal on the marble platform, reserve a gap of 1mm between them, and use two quartz bricks 30 to limit them, the limit between the two quartz bricks The position is less than 1 / 3 of the circumference of the large quartz tube, and the contact between the quartz brick and the large quartz tube is provided with an arc-shaped chamfer;

[0043] D. Weld three welding spots 20 evenly distributed along the circumference with solder at the gap betwe...

Embodiment 2

[0058] Embodiment 2: prepare a diameter and be 480mm, the quartz large tube that length is 3500mm

[0059] Include the following steps:

[0060] A. Take two large quartz tubes with a length of 2000mm and a diameter of 480mm, cut one of them to obtain a tube A with a length of 1550mm for use, and then take an uncut tube B with a length of 2000mm for use, and carry out the two tubes respectively unilateral pour;

[0061] B. Clean and dry the pour end;

[0062] C. Put the pour ends of tube A and tube B facing each other and keep the axis horizontal on the marble platform, reserve a gap of 1mm between them, and use two quartz bricks 30 to limit them, the limit between the two quartz bricks The position is less than 1 / 3 of the circumference of the large quartz tube, and the contact between the quartz brick and the large quartz tube is provided with an arc-shaped chamfer;

[0063] D. Weld three welding spots 20 evenly distributed along the circumference with solder at the gap bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com