Preparation method of electric brush for treadmill motor and electric brush prepared by the method

A technology of electric brushes and raw materials, applied in the fields of electric brushes for treadmill motors and their preparation, and electric brushes for electric motors, can solve the problems of easy occurrence of mechanical sparks, poor use performance of electric brushes, poor ability to suppress sparks, etc., and achieves mechanical processing. Excellent performance, strong anti-interference and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

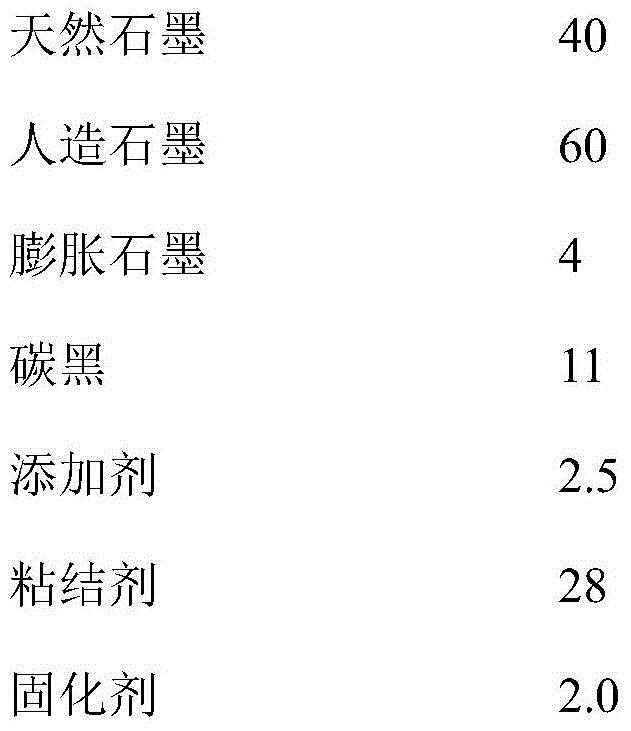

[0056] 1. Prepare materials according to the following weight ratio (kg):

[0057]

[0058] Among them, the additives include molybdenum disulfide and paraffin, and the weight ratio of molybdenum disulfide and paraffin is 1:1.5; the binder is bisphenol A epoxy resin, and its epoxy value is 0.25-0.45; the curing agent is selected from Latent curing agent T-31 curing agent (Changzhou Shanfeng Chemical Co., Ltd.);

[0059] 2) Put the raw materials of natural graphite, artificial graphite, expanded graphite, carbon black, additives, and curing agent in the kneading pot, turn on the heating device of the kneading pot, heat up to 150°C, and stop heating after mixing at 150°C for 2 hours. The material is cooled to ≤40°C to obtain a premix;

[0060] Heating to remove impurities such as moisture and ash in the raw material to ensure that the moisture content in the raw material is <0.5%.

[0061] 3) Dissolve 28kg of adhesive epoxy resin in 45kg of acetone and mix evenly to obtain ...

Embodiment 2

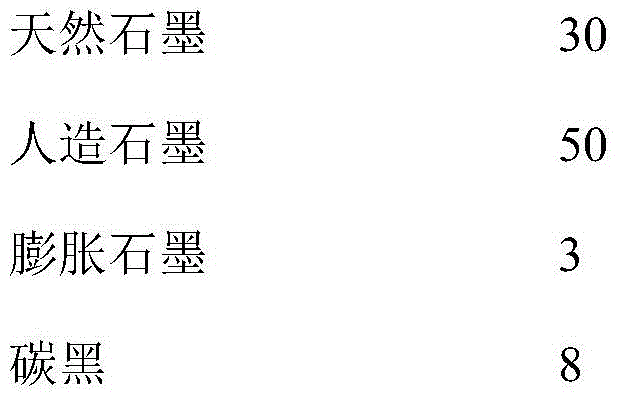

[0070] 1. Prepare materials according to the following weight ratio (kg):

[0071]

[0072]

[0073] Among them, the additives include molybdenum disulfide and paraffin, and the weight ratio of molybdenum disulfide and paraffin is 0.5:1; the binder is bisphenol A epoxy resin, and its epoxy value is 0.25-0.35; the curing agent is selected from Latent curing agent adipic acid dihydrazide (Wuxi Liangxi Fine Chemical Co., Ltd.).

[0074] 2) Put the raw materials of natural graphite, artificial graphite, expanded graphite, carbon black, additives, and curing agent in the kneading pot, turn on the heating device of the kneading pot, heat up to 170°C, mix at 170°C for 1.5h, and stop heating. After the material is cooled to ≤40°C, the premix is prepared;

[0075] 3) Dissolve 20kg of binder epoxy resin in 35kg of acetone and mix well to obtain a binder solution;

[0076] 4) Add the binder solution into the premix and stir, mix evenly, stir for 1 hour, take out the material af...

Embodiment 3

[0083] 1. Prepare materials according to the following weight ratio (kg):

[0084]

[0085] Among them, the additives include molybdenum disulfide and paraffin, and the weight ratio of molybdenum disulfide and paraffin is 1.5:2; the binder is bisphenol A epoxy resin, and its epoxy value is 0.25-0.45; the curing agent is selected from Epoxy resin latent curing agent T-31 curing agent.

[0086] 2) Put the raw materials of natural graphite, artificial graphite, expanded graphite, carbon black, additives, and curing agent in the kneading pot, turn on the heating device of the kneading pot, heat up to 160°C, mix at 160°C for 1.5h, and stop heating. After the material is cooled to ≤40°C, the premix is prepared;

[0087] 3) Dissolve 24kg of binder epoxy resin in 40kg of acetone and mix well to obtain a binder solution;

[0088] 4) Add the binder solution into the premix and stir, mix evenly, stir for 1.5 hours, take out the material after mixing evenly, place it at room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com