Powder metallurgy brake shoe for electric locomotive

A technology of powder metallurgy and electric locomotives, applied in the direction of mechanical equipment, friction linings, brake parts, etc., can solve the problems of train braking, tread wear, cracks or peeling, etc., and achieve excellent machining performance and lubricating performance OK, add reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

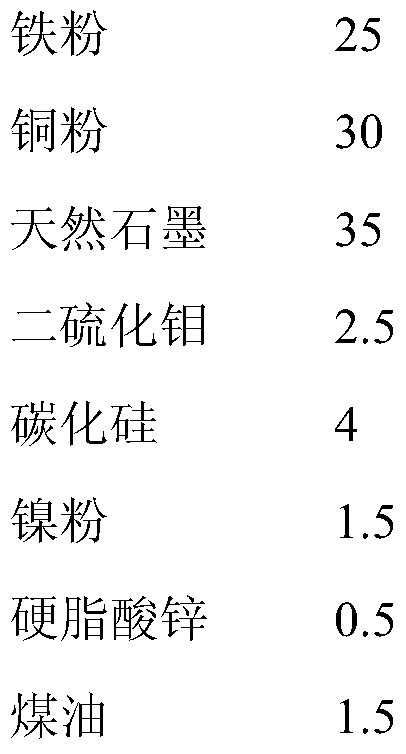

[0101] 1. Prepare the raw materials according to the following proportions by weight:

[0102]

[0103] 2. Under normal temperature, iron powder, copper powder, additives and zinc stearate are uniformly mixed to obtain the first premix; then natural graphite and kerosene are uniformly mixed to obtain the second premix; The first premix and the second premix were added to the mixing equipment and mixed for 7 hours to prepare the premix.

[0104] 3. Put the premixed material in a mold for pressing treatment. The pressing equipment is a 315-ton hydraulic press with a pressing specific gravity of 5.3 to obtain a tile-shaped powder metallurgy brake shoe friction block blank.

[0105] 4. Roast the tile-shaped powder metallurgy brake shoe friction block blank, firstly increase the temperature of the sintering furnace to 1050°C within 5.5 hours, then keep it at this temperature for 4.5 hours, and then cool it to room temperature with cold water to obtain A tile-shaped powder metal...

Embodiment 2

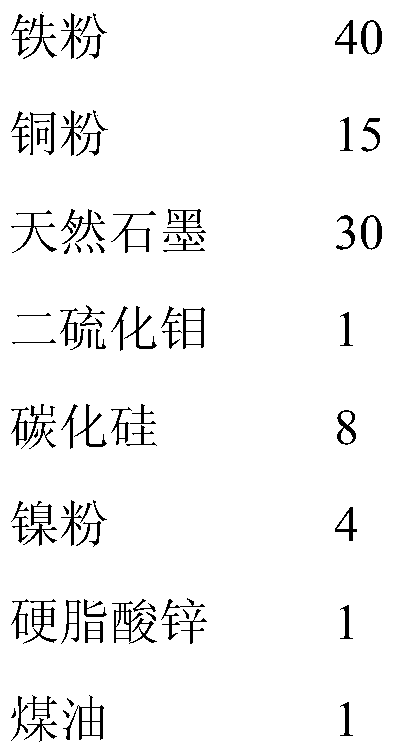

[0112] 1. Prepare the raw materials according to the following proportions by weight:

[0113]

[0114] 2. Under normal temperature, iron powder, copper powder, additives and zinc stearate are uniformly mixed to obtain the first premix; then natural graphite and kerosene are uniformly mixed to obtain the second premix; The first premix and the second premix were added to the mixing equipment and mixed for 6 hours to prepare the premix.

[0115] 3. Put the premixed material in a mold for pressing treatment. The pressing equipment is a 315-ton hydraulic press with a pressing specific gravity of 5.6 to prepare a powder metallurgy brake shoe friction block blank.

[0116] 4. Roast the powder metallurgy brake shoe friction block blank, firstly increase the temperature of the sintering furnace to 1000°C within 5 hours, then keep it at this temperature for 6 hours, and then cool it to room temperature with cold water to obtain a tile-shaped powder metallurgy Brake shoe friction b...

Embodiment 3

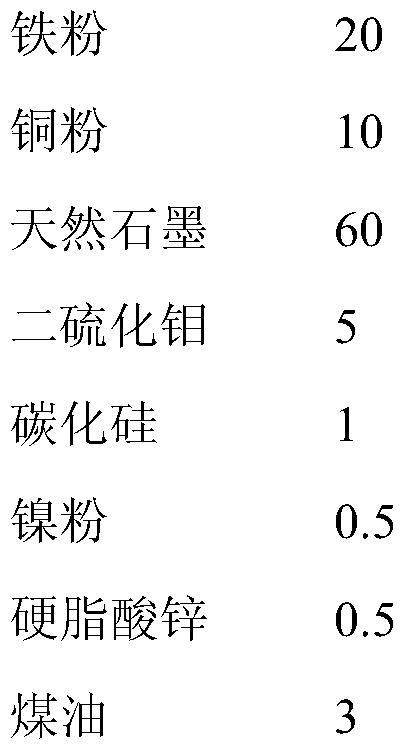

[0123] 1. Prepare the raw materials according to the following proportions by weight:

[0124]

[0125] 2. Under normal temperature, iron powder, copper powder, additives and zinc stearate are uniformly mixed to obtain the first premix; then natural graphite and kerosene are uniformly mixed to obtain the second premix; The first premix and the second premix were added to the mixing equipment and mixed for 10 hours to prepare the premix.

[0126] 3. Put the premixed material in a mold for pressing treatment. The pressing equipment is a 315-ton hydraulic press with a pressing specific gravity of 5.0 to prepare a powder metallurgy brake shoe friction block blank.

[0127] 4. Roast the powder metallurgy brake shoe friction block blank, firstly increase the temperature of the sintering furnace to 1100°C within 6 hours, then keep it at this temperature for 3 hours, and then cool it to room temperature with cold water to obtain a tile-shaped powder metallurgy Brake shoe friction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com