Hydraulic tensioner for timing chain of engine

A technology of hydraulic tensioner and engine, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., to reduce the risk of abnormal chain system, simple structure and installation, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

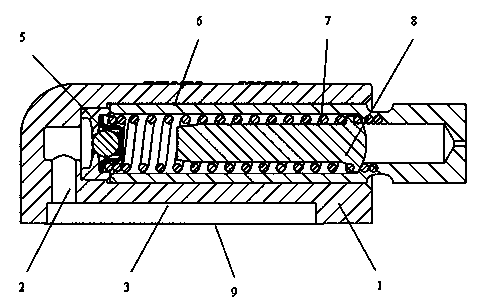

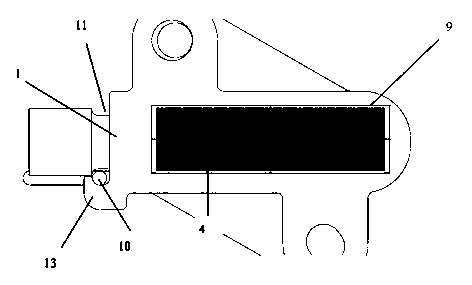

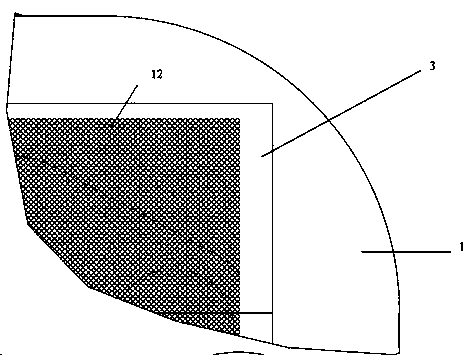

[0019] like figure 1 As shown, the tensioner is composed of a housing 1, a one-way valve 5, a piston 6, a spring 7, a plunger 8 and a metal filter 9, and the piston 6, spring 7 and plunger 8 are installed in the inner cavity of the housing 1 In 4, an oil storage chamber 3 is opened on one side of the housing 1, and the oil storage chamber 3 is connected to the inner cavity through the oil inlet hole 2, and the outside of the oil storage chamber is connected with the oil passage of the engine, and the metal filter screen 9 is covered on this side. The engine oil in the oil storage chamber 3 comes from the engine. Oil is introduced into the housing cavity 4 through the oil inlet hole 2 . The one-way valve 5 is arranged between the oil inlet hole 2 and the inner cavity 4 of the housing. When the oil pressure from the oil inlet hole 2 is greater than a certain value, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com